Laser Cladding of cermets for high-temperature erosive wear resistance for thermal power plant components

- Developed the process by co-deposition of NiCr-Cr3C2 powder on SS-310 steel.

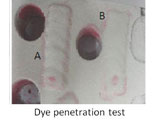

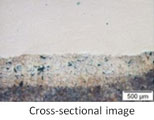

- The produced clad is crack-free and defect-free with

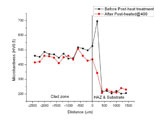

- A hardness of 1200-1400HV

- 2% dilution

- Clad thinckness of 0.9mm with uniform hardeness

- A seven-fold improvement in erosive wear resistance

Laser cladded boiler component