Power & Energy

2D-Nanolayered Transition Metal Sulfides (2D-NTMS)

Overview

Two dimensional nanosheet like structure in sulfides of transition metals like tungsten and molybdenum have shown wide range of attractive properties, which can be harnessed for various applications as catalyst or lubricant in petrochemical and automotive sectors, electrode material for Li-ion batteries and electrocatalyst for hydrogen evolution reaction (HER), etc. However, the absence of commercially viable routes for their synthesis in bulk quantity and reproducible quality has been a major issue hindering their commercial exploitation. Recently, a novel technique has been developed by ARCI to generate such 2D structure in WS2 and MoS2. The process offers unique control capabilities to synthesize tailor-made 2D nanolayered structure in these sulfides in bulk amount. Based on the application and/or required properties, the size and thickness of these nanosheets can be altered by changing various process control parameters.

Key Features

- Synthesis of pure as well as mixed WS2/MoS2 nanosheet powders

- Synthesis of doped-WS2/MoS2 nanosheet powders

- Reasonably good oxidation resistance

- Synthesis of 2D-nanostructured other transition metal sulphides feasible

- Scalable process for bulk production

Potential Applications

- Solid lubricant for aerospace and automotive sector

- Solid lubricant for forging and other manufacturing processes

- Additive to automobile Lub-oil

- Additive to grease for improved performance under high shear stress

- Petrochem catalyst

- Electrocatalyst for HER

- Li-ion battery electrode

- Self-lubricating composites and coatings (metallic/ceramics/polymer)

- Sensors and actuators

Intellectual Property Development Indices (IPDI)

- Stability in air validated at laboratory scale

- Consistency of the powder grade tested

- Scaled-up reactor successfully commissioned and tested for bulk production of 2DWS2/MoS2

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- . J. Joardar and M.S. Sylvester, Indian Patent (Ap. No. 1703/DEL/2012).

Major Publications

Oxide Dispersion Strengthened Steels for High Temperature Applications

Overview

Oxide dispersion strengthened (ODS) Ferritic-Martensitic/Ferritic/Austenitic steels are endowed with high temperature strength and resistance to creep, fatigue, oxidation and hot corrosion. Hence, these steels are potential candidates for the components in nuclear reactors, gas and ultra super critical steam turbines which are exposed to temperatures up to about 700C. The high temperature properties of ODS steels are due to the fine grained microstructure, nanosized oxide (Y-Ti-O complex) dispersoids and stability of the microstructure at high temperatures. ARCI has embarked on major programmes for development and demonstration of technologies for the manufacture of blades for ultra super critical steam turbines, clad tubes of fast breeder reactor and high pressure compressor and low pressure turbine blades for gas turbines.

Key Features

- High operating temperature of 650-700°C

- High yield strength and creep resistance

- Potential candidates to replace nickel based super alloys

- Resistance to swelling under irradiation

- Established manufacturing processes

Potential Applications

- Blades for ultra super critical steam turbines

- High pressure compressor and low pressure turbine blades of gas turbines

- Clad tubes for nuclear reactors

- Structural materials for fusion reactors

- Other high temperature applications

Intellectual Property Development Indices (IPDI)

- Established manufacturing processes at pilot plant scale

- Performance and stability are validated at prototype level

- Further evaluation is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- S. Santra, S. Amirthapandian, A. J. London, B. K. Panigrahi, R.M. Sarguna, S.Balaji, R.Vijay, C. S. Sundar and C. Grovenor, Effect of Ti and Cr on dispersion and structure of oxide nano-particles in model ODS alloys, Acta Mater. 97 (2015) 223-233.

- M. Nagini, R. Vijay, Koteswararao V. Rajulapati, K. Bhanu Sankara Rao, M. Ramakrishna, A.V. Reddy and G. Sundararajan, Effect of process parameters on microstructure and hardness of oxide dispersion strengthened 18Cr ferritic steel, Metall Mater. Trans. A, 47 (2016) 4197-4209

- K. Suresh, M. Nagini, R. Vijay, M. Ramakrishna, Ravi C. Gundakaram, A.V. Reddy and G. Sundararajan, Microstructural studies of oxide dispersion strengthened austenitic steels, Mater. Design, 110 (2016) 519-525.

- M. Nagini, R. Vijay, Koteswararao V. Rajulapati, A.V. Reddy and G. Sundararajan, Microstructure-mechanical property correlation in oxide dispersion strengthened 18Cr ferritic steel, Mater. Sci. Eng. A, 708 (2017) 451-459.

- M. Nagini, K.G. Pradeep, R. Vijay, A.V. Reddy, B.S. Murthy, G. Sundararajan, A combined electron microscopy, atom probe tomography and small angle X-ray scattering study of oxide dispersion strengthened 18Cr ferritic steel, Mater. Char., 164 (2020) 110306

Major Publications

High performance silicon carbide (SiC) tubes

Overview

SiC tubes have emerged as potential candidate material in the area of concentrated solar power generation, heat exchangers for recovery of heat from industrial waste, fuel cladding in nuclear reactors because of superior thermos-mechanical properties, high thermal conductivity, resistance to chemical attack and nuclear radiation. ARCI has developed the process for producing SiC tube by extrusion as well as cold iso-static pressing technique followed by sintering.

Key Features

- Extrusion press is capable of producing long tubes of different diameter and wall thickness.

- High production rate.

- Process flexibility to produce dense and porous SiC tubes.

Potential Applications

- Tubular solar receiver in CSP technology.

- Heat exchanger.

- Nuclear fuel cladding tubes.

- Support tubes in membrane separation.

Intellectual Property Development Indices (IPDI)

- SiC tubes produced by both extrusion and cold-isostatic pressing have been produced and properties tubes are being evaluated.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- S. Mubina, A. K. Khanra and B. P. Saha, Processing of sintered and CVD coated SiC/CNFs thin composite tubes, Mater. Chem. Phys., 220 (2018), 225-232.

Autogenous Laser Welding of Modified 9Cr-1Mo steel

Overview

Modified 9Cr-1Mo (P91) steel finds its usage in high temperature applications such as in supercritical and ultra super critical power plants. The weldability issues in P91 steel such as formation of delta ferrite in the fusion zone reducing the creep properties, hydrogen induced cracking due to high hardness in as-welded condition and Type-IV cracking in the intercritical zone away from the Heat Affected Zone (HAZ) are expected to be obviated through low heat input welding technique. Autogenous laser welding a low heat input technique when applied on 6 mm thick P91 steel plates using high beam quality (Gaussian,K>0.96) DC035 slab CO2 laser using a focal spot size of 180 µm could successfully address the above stated challenges.

Key Features

- Welds free from both hot and cold cracks and also fusion zone free of delta ferrite and no intercritical soft zone.

- The welds have 100 % joint efficiency with failure away from the weld in tensile testing and the welds have sufficient bend ductility.

Potential Applications

- Power plant

- Nuclear industry

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at coupon level

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- B. Shanmugarajan, G. Padmanabham, Hemant Kumar, S.K. Albert and A.K.Bhaduri, “Autogenous laser welding investigations on modified 9Cr-1Mo (P91) steels”, Science & Technology of Welding and Joining, Vol.6, No.6, 2011, p528

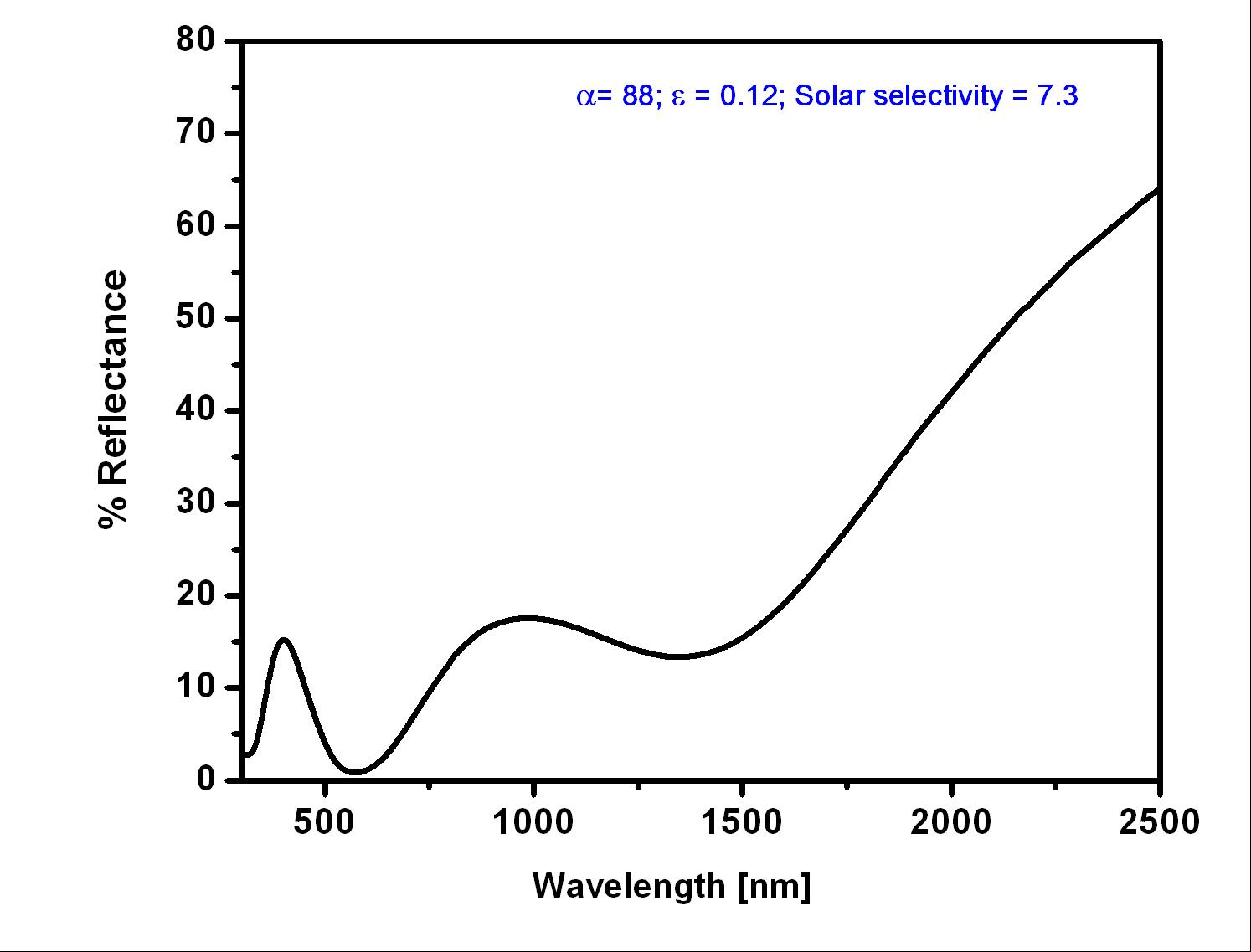

Design and development of open air compatible state-of-the-art solar selective coating for high temperature concentrated solar thermal power generation applications

Overview

The major objective of the project includes;

- To develop a wear resistant and high temperature stable (~ 500°C) metal nitride based hydrophobic solar selective coatings for concentrated solar power generation (CSPG) applications using Cathodic Arc Physical Vapor Deposition (CAPVD) Technique.

- To demonstrate state-of-art selective properties (α ~ 95%; ε < 0.15 at 500°C), high temperature and environmental stability of the developed receiver tube (with an overall length of 1.0 m). Also, evaluating the commercial viability in CSPG.

- To compare and analyze the cost effectiveness in indigenization of the receiver tube technology.

Key Features

The key features of the project include obtaining state-of-the-art selective properties (α ~ 95%; ε < 0.15 at 500°C) and demonstrating indigenously developed 1 m receiver tube.Potential Applications

The technology will be highly useful in solar thermal applications for generating electricity.Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- “An improved solar selective multi-layer coating and a method of depositing the same” application No.1567/DEL/2012, May 22nd 2012.

Major Publications

- “High temperature stable solar selective coatings by cathodic arc PVD for heat collecting elements” Krishna Valleti, D. Murali Krishna, P. Mohan Reddy, Shrikant V. Joshi, Solar Energy Materials and Solar Cells 145 (2016):447

- “Functional multi-layer nitride coatings for high temperature solar selective applications” Krishna Valleti, D. Murali Krishna, S.V. Joshi, Solar Energy Materials and Solar cells 121 (2014): 14

Large Scale Production of Lithium Titanate (Li4Ti5O12) Electrode Materials by Cost-effective & High Energy Milling Process

Overview

Lithium ion batteries play an important role in the field of electric vehicle (EV) industries due to their high energy density and power density in comparison to other secondary batteries. As there is a great demand for large quantities of electrode materials for EV application, ARCI is working on development of nano-structured electrode materials in large scale by cost-effective processes. Lithium titanium oxide (LTO) has emerged as a promising anode material for high-power LIBs owing to its abundance, low manufacturing cost, thermal stability, excellent cycle life of 20000 cycles and safety. LTO is also known as a ‘zero-strain’ material because it undergoes negligible volume change during charginf/discharging, which ensures an extremely long cycle life. Further, LTO anode based Li-ion batteries can work under harsh ambient temperatures (-30 to +55°C) and exhibit recharge efficiency exceeding 98%, compared to other carbon based anode materials. Hence, it is ideal for Indian climatic conditions where the temperature reaches 45-48 0C in summer, which is a motivating factor for indigenous LTO materials development. ARCI focused on developing the simple, economical scalable and energy efficient technique for production of LTO anode with improved electronic conductivity using TiO2 and Li2CO3 as precursors. The advantages of high energy milling method are short processing time, low contamination, high relative velocity of balls and high energy input. Further, ARCI’s technology has been tuned to be adaptable to any sort of precursers ARCI’s LTO has been validated in half cell and its performance was found to be very promising in terms of high specific capacity (170 mAh/g), good rate capability (20C) and long cyclic stability (upto 1000 cycles), which is better than the performance of coomercial LTO obtained from Geylon, China as it exhibits capacity of only 113 mAh/g with poor rate capability. Further LTO based LIB device (20 mAh capacity) fabricated in combination with high voltage cathode exhibited 80% retention of capacity after 1000 cycles. The production cost of ARCI’s LTO is comparable with the cost of imported LTO (~ 20 USD) by utilizing the pilot plant facility for the production of LTO at a level of 72kg/day. Patents are filed in India, USA, Japan, China, Germany and South Korea. A private company, who is making LTO based LIB for Hybrid Vehicle application is very much interested in ARCI’s LTO technology and efforts are underway for possible technology transfer.

Key Features

- Large scale production (2.5 Kg/batch) of lithium titanate (LTO) by high energy milling process

- Simple, economic and scalable processing method.

- Electrochemical performance of LTO is higher than commercial LTO material

- Capable of delivering high power performance

- Prototype LTO electrodes of 30 m length was prepared using LIB plant facility.

- LTO based LIB device (20 mAh capacity) with high voltage cathode

- 80% retention of capacity after 1000 cycles

Potential Applications

- High power density and thermally stable anode for electric hybrid electric vehicles

- Other portable devices where LIB s are used.

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up has been carried out successfully

- Prototype testing is under process using pilot plant facility.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, Indian Patent Application No. 201711006147 dated 27.12. 2017.

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, PCT International Application No. PCT/IN2018/050080 dated 17.02.2018.

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, US Patent Application No. 16/463,088 dated 22rd May 2019 based on PCT International Application No. PCT/IN2018/050080 dated 17.02.2018.

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, Japan Patent Application No. 2019-520394dated 16th April 2019 based on PCT International Application No. PCT/IN2018/050080 dated 17.02.2018.

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, Chinese Patent Application No. CN201880004507 dated 22nd July 2019 based on PCT International Application No. PCT/IN2018/050080 dated 17.02.2018.

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, Germany Patent Application No. 112018000205 T5 dated 14th August 2019 based on PCT International Application No. PCT/IN2018/050080 dated 17.02.2018

- A method of producing high performance lithium titanate anode material for lithium ion battery applications, S. Anandan, P.M. Pratheeksha, R. Vijay and Tata N. Rao, South Korea Patent Application No. 10-2019-0121291dated 25thOctober2019 based on PCT International Application No. PCT/IN2018/050080 dated 17.02.2018.

Major Publications

Development of High Performance Carbon coated LiFePO4 by a Cost-effective and Scalable Process

Overview

Lithium ion batteries play an important role in the field of electric vehicle (EV) industries due to their high energy density and power density in comparison to other secondary batteries. Though there exists a great demand for large quantities of electrode materials for EV application, many research groups focus on basic (lab scale R&D) research rather than large scale production of electrode materials. In contrast, ARCI focuses mainly on development of nano-structured electrode materials in large scale by cost-effective processes. Among cathode materials, LiFePO4 becomes promising for electric vehicle batteries due to their high energy density, structural and thermal stability.ARCI successfully developed a rapid, simple and cost-effective process to prepare in-situ carbon coated LiFePO4 (C-LFP) in large scale by adopting solid-state high-energy milling technique. The C-LFP so developed shows promising electrochemical properties in terms of high charge discharge capacity, excellent rate capability and long cyclic stability and hence it may be suitable for high energy as well as high power density lithium-ion battery application. The method developed for synthesizing C-LFP in this invention has the advantage of being cost effective, single step, and fast processing due to high kinetic energy system used for milling of powders.

Key Features

- Methods which can produce 2kg of nano-powders were used for large scale production of carbon coated LiFePO4 (C-LFP)material.

- The method was found to be economical simple and scalable.

- Has the potential to fine tune the properties of cathode produced.

- Electrochemical performance of C-LFP at par with commercial C-LFP and the method is scalable.

- Prototype LIB cells fabrication & demonstration using indigenous C-LFP material.

Potential Applications

- High energy density cathode for electric vehicles

- High power density cathode for marine application

- Other portable devices where LIB s are used.

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up has been carried out successfully

- Prototype testing is under process using pilot plant facility.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- Method of producing in-situ carbon coated lithium iron phosphate cathode material for Li-ion Batteries and the product thereof, S. Anandan, R. Vijay and Tata N. Rao, Indian Patent Application No. Application number 202011056608 dated 28th December 2020

Major Publications

Development of Porous carbon for high performing Supercapacitors

Overview

Super capacitors have been recognized as promising energy storage devices due to their fast charge-discharge time, very high power density and long life cycle period. It is commercially available but widespread usage is restricted by their high cost and low energy density. These drawbacks can be mitigated by developing a new class of high performance carbon electrodes which consist of a combination of materials produced from abundant, cheap and environmentally friendly resources with low processing costs. ARCI focuses mainly on the development of large scale process to convert various bio-wastes into a high surface area porous carbon material with graphitic structure suitable for super capacitor application. ARCI successfully synthesized high performance porous carbon materials using bio-waste like jute stick, cotton fabric by a simple chemical activation process. The resulting carbon material delivers excellent super capacitor performance in terms of capacitance, rate capability and cyclic stability in comparison to commercial activated carbon material. Also, ARCI in collaboration with HPCL has developed graphene-like activated porous carbon from petroleum coke (Petcoke) by a low-cost chemical activation process and demonstrated its superior electrochemical properties in comparison to commercial supercapacitor grade carbon. Petcoke, a by-product in oil refining process, is a rich carbon source material (> 90%) and also contains significant amount of sulfur impurity. There is an environmental concern of using petcoke as low cost fuel in cement and steel industries due to the emission of hazardous CO2 and SOx gases. Alternatively, use of petcoke for energy storage application abates the emission problem while finding a high value addition to it. A semi-pilot plant involving various equipments such as the coating machine, Semi-auto winding machine, Grooving machine, Sealing machine, flattening machine, Electrolyte filling machine etc are installed at ARCI and are functional for fabricationg cylindrical supercapacitor cells. Large scale synthesis of materials in Kg level is optimized to make carbon slurry and the jelly rolls obtained from coated electrodes are laser welded to achieve large area electrical contact to terminals and demonstrated the first indigenous 1200 F supercapacitor that performs on par with a benchmark commercial supercapacitor. For comparison, the performance of commercial supercapacitor device obtained from market was also validated under similar experimental conditions and the indigeneous device exhibits performance onpar with the commercial device. Cyclic Voltammetry studies were performed at 1 mV/s for both indigenous cell and commercial cell. The capacitance was calculated to be 1198 F at 1 Amp. for indigenous ARCI cell with a voltage window of 2.7 V. The total energy stored is about 1.2 Wh for indigenous ARCI cell with a energy density of 5.01 Wh/Kg, whereas the energy stored for commercial device is about 1.18 Wh with a energy density of 4.5 Wh/Kg.

Key Features

- Facile synthesis of porous carbon by a simple chemical activation process

- Graphene like structured carbon, high surface area, large pore volume

- Conversion of abundant solid waste into useful carbon material

- Specific capacitance, rate capability and cyclic stability higher than commercial carbon

- High energy density based supercapacitor

- Scalable manufacturing process

- First Indigenous 1200 F supercapacitor

Potential Applications

- Automotive transport (electric bus, electric bicycles, electric cars)

- Consumer electronics (voltage stabiliser, grid power buffer, street lamps)

- Energy recovery (trams, cranes, tractors)

- Memory backup for static random-access memory (SRAM)

Intellectual Property Development Indices (IPDI)

- Synthesis and electrochemical performance of porous carbon at laboratory scale

- Scale-up of porous carbon from bio-waste is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- K. Nanaji, V. Pavan Srinivas, S. Anandan, T. Narasinga Rao, K. Narayanan, B. Ramachandra Rao and M. Pramanik “Method of producing nanoporous graphene sheet-like structured high and low surface area carbon sheets from petroleum coke” (Patent number: No.202011007399 dt. 20/2/2020).

- S. Anandan, K. Nanaji, and T. Narasinga Rao, “Method of producing graphene like structured nanoporous carbon material from Jute stick based bio-waste for Energy Storage applications and the product thereof” (Patent number: No.E-2/276//2018/DEL dt. 16/2/2018).

- Mani Karthik, Ravula Vijay, Tata Narasinga Rao, “Method of producing porous particles-fibers carbon composites for supercapacitor applications and the product thereof (Patent number: No. 202011027265 dt. 26/06/2020).

Major Publications

- K. Nanaji, Varadaraju U.V, Tata N. Rao, S. Anandan “Robust, Environmentally Benign Synthesis of Nanoporous Graphene Sheets from Biowaste for Ultrafast Supercapacitor Application”, ACS Sustainable Chemistry & Engineering, 2019, 7, 2516-2529.

- K. Nanaji, Hari Mohan. E, Sarada V. B, Varadaraju U.V, N. Rao Tata, Anandan. S, “ One step synthesized hierarchical spherical porous carbon as an efficient electrode material for lithium ion battery”, Materials Letters, 2019, 237, 156-160.

- K. Nanaji, Tata N. Rao, Varadaraju U.V, S. Anandan, “Jute sticks derived novel graphitic porous carbon nano sheets as Li-ion battery anode material with superior electrochemical properties” International Journal of Energy Research, 2020, 44, 2289-2297

- M. Vijayakumar, A. Bharathisankar, D. S. Rohita, K. Nanaji, Tata N. Rao, M. Karthik, "Achieving High Voltage and Excellent Rate Capability Supercapacitor Electrodes Derived from Bio-renewable and sustainable Resource" ChemistrySelect, 2020, 5, 8759-8772.

- E. Hari Mohan, K. Nanaji, S. Anandan, B.V. Appa Rao, Tata N. Rao “Porous Graphitic Carbon Sheets with High Sulfur Loading and Dual Confinement of Polysulfide Species for Enhanced Performance of Li-S Batteries” Journal of Materials Science, 2020, 55, 16659-16673.

- T. Mitravinda, K.Nanaji , S. Anandan, A. Jyothirmayi, Ch. Sai Kiran, Tata N Rao, Chandra Sharma, “Facile synthesis of corn silk derived nanoporous carbon for an improved supercapacitor performance”, Journal of The Electrochemical Society, 2018, 165 (14), A3369-A3379.

- E. Hari Mohan, K. Nanaji, S. Anandan, S.V. Bulusu, B.V. Appa Rao, T.N. Rao, One-step Induced Porous Graphitic Carbon Sheets as Supercapacitor Electrode Material with Improved Rate Capability, Materials Letters, 2019, 236, 205-209

- Manavalan Vijayakumar, Ammaiyappan Bharathisankar, Duggirala Sri Rohita, Tata Narasinga Rao, Mani Karthik, Conversion of Biomass Waste into High Performance Supercapacitor Electrodes for Real-Time Supercapacitor Applications, ACS Sustainable Chemistry & Engineering, 2019, 7, 17175-17185.

- Manavalan Vijayakumar, Ravichandran Santhosh, Jyothirmayi Adduru, Tata Narasinga Rao, Mani Karthik, Activated carbon fibres as high performance supercapacitor electrodes with commercial level mass loading, Carbon, 2018, 140, 465-476.

- K. Nanaji, A. Jyothirmayi, U.V. Varadaraju, Tata N. Rao, S. Anandan, “Facile synthesis of mesoporous carbon from furfuryl alcohol-butanol system by EISA process for supercapacitors with enhanced rate capability”, Journal of Alloys and Compounds, 2017, 723, 488-497

- K. Nanaji, Varadaraju U.V, Tata N. Rao, S. Anandan, “Pore size engineered three dimensional ordered mesoporous carbons with improved electrochemical performance for supercapacitor and lithium ion battery applications” ChemistrySelect, 2019, 4, 10104 -10112

Axial Suspension Plasma Spray (ASPS)

Overview

Specifications

- High energy plasma power upto 150 kW to spray wide ranging ceramics, cermets, alloys, metal powders and fine particle suspensions

- Plasma jets: up to three, converging mode using Argon, Nitrogen, Hydrogen

- Axial Feedstock injection along the plasma flow

- Dual feed Axial Plasma Spray Torch configured to spray powders and suspensions

- Six-axis Robotic handling

Details

High energy Axial Plasma spray technique is capable to spraying powders and fine particle suspensions. In comparison with conventional radially injected plasma spray systems, the axially injected powder particles attain better momentum and greater heat transfer while travelling along the plasma plume. Therefore, the axial plasma sprayed coatings exhibit good deposition rate and efficiency and also, offer possibilities of engineering the microstructure with dense, porous and cracked features.

Fine structured coatings provide improved properties than micron-sized coatings. However, the fludized powder feeding arrangement are incapable of injecting fine particles, which necessitates the use of liquid based feeding either as suspensions or solution precursor based spraying. Additional capabilities of axial plasma spraying can be realized through efficient spraying of fine particle suspensions which otherwise are difficult with radial injection systems. Axial suspension plasma spray (ASPS) is an emerging coating technology through the use of fine-sized powder particles suspended in a suitable solvent such as water or ethanol and injected into the plasma flame to get desired microstructure. Unique features of axial suspension plasma spray are,

- Tailored microstructure – dense, porous, columnar, vertically cracked, feathery

- High spray rate

- Relatively thin coatings are possible compared to conventional thermal spray

- Better surface finish

- Wide range of materials – cermets, ceramics, metals and alloys

Prominent application areas with axial plasma spray technique include industries requiring thermal barrier, dielectric, insulation, wear, corrosion resistance and refurbishment. For example, YSZ based thermal barrier coatings applied through ASPS exhibit lower thermal conductivity and identical microstructure similar to that EBPVD process, which can be effectively exploited for cost-effective thermal barrier coatings in gas turbine components.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Activated Combustion High Velocity Air-Fuel (HVAF)

Overview

Specifications

- Capable to generate 200 kW equivalent combustion power to spray wide ranging cermets, alloys and metal powders

- Convertible mode of spraying to deposit higher particle sized powders

- Internal geometry coating capability

- Specialized torch for spraying Carbide coatings and thin wear resistant coatings

- Six-axis Robotic handling

Details

Activated Combustion High-velocity Air-Fuel (HVAF) spray utilises compessed air and LPG fuel combination to generate high velocity gas streams. The optimized combination of high kinetic energy – ideal thermal input allows deposition of coatings with excellent microstructural features including fully dense, defect-free, retained phases and high adhesion strength. The exceptional capabilities can be understood from its highest productivity amongst the competing thermal spray techniques to reach as high as 35 kg/hr for Cr3C2-NiCr based coatings.

The process involves a pre-mixed Air-fuel mixture fed to the combustion chamber through the ceramic insert which is ignited initially with a spark plug. As the Combustion proceeds, the ceramic insert at the entrance of the combustion chamber gets heated up above the auto-ignition temperature of the mixture and takes the role of spark plug to enable stable combustion (also known as “Activated combustion”) throughout the process. The flame temperature during HVAF is much lower than that of HVOF since it uses an air-fuel mixture instead of an oxy-fuel mixture, which allows HVAF to coat thermally sensitive material with lesser thermal deterioration. Control of gas dynamics through the use of diverse nozzles results in range of particle velocities, which translates into highly adhesive, hard, oxide and pore-free coatings. Prominent application sectors with HVAF technique include industries requiring wear, corrosion resistance and refurbishment.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Electrodeposited nanostructured NiCo2O4 based supercapacitor

Overview

With the anticipated increase in the renewable wind and solar energy supercapacitors with high specific capacitance and cycle stability have increasing demands to balance the energy storage requirements. NiCo2O4 based electrode materials with excellent electrochemical performance and high theoretical specific capacitance values serve as emerging tool for various applications like HEV’s and back-up systems. Further, electrodeposition is a cost-effective mode of synthesis both with respect to the materials employed and the equipment used. The technology aims at the synthesis of binder free electrodeposited NiCo2O4 electrode materials for supercapacitors along with the fabrication of device for practical applications

Key Features

- Cost effective synthesis strategy

- High specific capacitance (1977 F/g at 1 A/g by half cell and 91.5 F/g at 0.5 A/g by full cell)

- High power density (7.5 kW/kg at 10 A/g)

- Good capacitive retention of the ASC (74% retention for 5000 cycles)

Potential Applications

- Start-Stop systems

- HEV’s

- UPS and back-up systems

- Electronics

- ASC device performance and stability for 5000 cycles has been validated at lab scale

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Batteries and Supercaps, 2020, 3, 1209– 1219

Nanostructured MnO2 electrode for Supercapacitor Applications

Overview

Aqueous supercapacitors with enhanced energy densities are much needed for their non-toxic and environmental benignity. Metal oxide based pseudocapacitors enhance the specific capacitance and energy density of the device by enlarging the potential window of aqueous electrolyte beyond 1.0 V along with faradic participation. Manganese oxide is an attractive material among the oxide materials used as electrode in supercapacitors because of its high specific capacity, non-toxicity, earth abundance and environmental compatibility. In the present work, β-MnO2 nanostructures have been electrodeposited on activated carbon paper as a binder and additive-free electrodes. Further, the effect of redox mediator in the electrolyte is assessed by fabricating ASC with various molar ratios of KI.

Key Features

- Economic synthesis strategy

- Wide active voltage window

- Energy density of 38.31 Wh/kg at a power density of 3.28 kW/kg

- Excellent capacity retention of 83.3% for 10,000 continuous CD cycles

Potential Applications

- Start-Stop systems

- HEV’s

- UPS and back-up systems

- Electronics

- ASC device performance and good retention for 10000 cycles have been validated at lab scale.

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Additive Manufacturing of AISI H13 Tool Steel: Die Tools with conformal cooling channels

Overview

AISI H13 tool steel is versatile material used in mould and die tools applications due to its excellent hot working property with good thermo-fatigue strength. Additive manufacturing of AISI H13 alloy leads to most efficient tooling application with possibility of complex designs with conformal cooling channels. AISI H13 being hardenable alloy with carbide precipitates is sensitive to rapid solidification involved in AM process. Hence, optimization of post heat treatment has been carried out to achieve the desired microstructure and required hardness and toughness in AM manufactured part. With developed knowledge on additive manufacturing of AISI H13 tool steel, a case study has been chosen with industrial partner and test the additively manufactured tool in real-time conditions.

Key Features

- Reduction in die temperature achieved between the two shots: In case study the core pin recorded a 15 to 20 % reduction in the die temperature.

- Reduced and delayed soldering effect: The soldering behaviour of the corepin with conformal cooling channel has improved. Surface porosity is reduced in size and numbers

- Reducing the number of rejections: Increase in production and reduced cost per part.

- Reduced Casting Cycle time: It has been confirmed that the cycle time has marginally reduced which results in increase of productivity.

- Tool Service life: Because of effective cooling the service life of the core pin has also increased as compared to the core pin without conformal cooling channel.

Potential Applications

- Pressure die casting tools

- High Temperature Extrusion tools

- Hot Forging tools

- Hot forming and Punching tools

Intellectual Property Development Indices (IPDI)

- Successfully completed testing of AM built PDC tools with conformal channels on real-time conditions (Case study)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Smart Hydrogen Supply Chain Supported Polymer Electrolyte Membrane Fuel Cell in Telecom Tower Power Backup

Overview

Key Features

- Demonstration of an indigenous PEMFC system based power backup for telecom tower application.

- Feasibility of geographically specific hydrogen supply chain Bottled hydrogen / Reformed hydrogen / Renewable hydrogen

- Demonstration of PV integrated electrochemical methanol reformer as a hydrogen source which will be first of its kind internationally

- Technology Readiness Level change from 5-6 to 7-8 owing to the field trails and industrial partnership leading to the technology adoption for commercial application.

- Demonstration of Hydrogen as a vector for energy storage

Potential Applications

- Provide the best option for cost effective hydrogen supply chain for PEMFC based back up power for telecom applications

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Development of High Performance Electrode Materials for Sodium Ion Battery Applications

Overview

Sodium ion batteries (SIBs) are considered to be next generation energy storage devises due to promising electrochemical performance, safety, low- cost and sustainability. They can be made from widely available and inexpensive resources for use in grid energy and heavy electric vehicle applications. Research is going on around the world to develop suitable electrode materials and electrolytes to achieve specific energy and cycle life similar to that of LIBs. ARCI embarked on major research to develop different cathode materials such as Polyanionic compounds with long cycle (>500 cycles) life and layered sodium transition metal oxides with high specific capacity (>160 mAh/g) and hard carbon with low sodium insertion potential (<0.2 V vs. Na/Na + ) and high specific capacity (>250 mAh/g) as anode using novel chemical methods. Electrochemical performances of these materials have been investigated using indigenously developed non-aqueous based electrolyte.

Key Features

- Abundance of Sodium; Low-cost

- High specific energy and power density; good rate capability; long cycle life

- High thermal stability and safe-in operation

Potential Applications

- Grid energy storage (EES); Stationary energy storage

- Heavy electric vehicles

- Strategic applications

Technology Readiness Level (TRL):

- Sodium vanadium phosphate (~500 g/batch) of specific energy ~357 Wh/kg with cyclic stability >500 cycle at 1 C-rate

- Sodium vanadium fluorophosphate (~500 g/batch) of specific energy ~425 Wh/kg at 5 C-rate (70% capacity retention after 500 cycles)

- Electrolytes with high ionic conductivity (>10 -3 S/cm) and electrochemical stability window (>4.2 V) has been prepared and tested

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- Microwave assisted sol-gel process for preparing in-situ carbon coated electrode materials and the product there of,” (2019) Bijoy Kumar Das, P. Laxman Manikanta, N. Lakshmipriya, R. Gopalan, G. Sundararajan, Indian Patent 201911008004 and European Patent: 20763813.1 (FER filed); Japanese Patent: 2020-550159 and Korean Patent: 10-2497808 (Granted).

- "High Energy-Power Characteristics of Hierarchical Nitrogen-Doped Mesoporous Carbon Decorated Sodium Vanadium Phosphate in Full cell level", P Laxman Mani Kanta, M Venkatesh, Satyesh Kumar Yadav, Bijoy Das*, R Gopalan, Applied Energy 334 (2023)120665.

- “Unusual Case of Higher Cyclic Stability at a Wider Voltage Window in Sodium Vanadium Phosphate” P Laxman Mani Kanta, N Lakshmi Priya, Prajeet Oza, M Venkatesh, Satyesh Kumar Yadav, Bijoy Das*, G Sundararajan, R Gopalan, ACS Appl. Energy Mater. 4 (2021) 12581-12592

Major Publications

Large Scale Production of Lithium Titanate (Li 4 Ti 5 O 12 ) Electrode Materials by Cost- effective & Solid State Process

Overview

Lithium ion batteries, which are critical to electric vehicles, play an important role in electric mobility. ARCI developed a simple, economical, scalable and energy efficient process for the production of LTO anode material by high energy ball milling with performance at par with commercial LTO. Subsequently LTO based 1.5 Ah 26650 cell as well as 0.45 Ah Pouch cells have been fabricated and validated. Large scale production process was established and demonstrated under public private partnership. The resulting LTO delivers superior rate capability of 137 mAh/g at 10C with long cyclic stability. Patents were filed in India as well as globally and were granted recently.

Key Features

- Large scale production (10-15 Kg/batch) of LTO by high energy milling process

- Simple, economic and scalable processing method.

- Electrochemical performance of LTO is higher than commercial LTO material

- Capability to deliver high power

- Evaluated the performance of the materials on 1.5 Ah 26650 cells as well as

Potential Applications

- High power density and thermally stable anode for electric hybrid vehicles

- Other portable devices where LIBs are used.

Technology Readiness Level (TRL):

- Performance and stability are validated at laboratory scale

- Scale-up has been carried out successfully

- Prototype devices of various form factors are being fabricated and validated

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

- Check repeatability/consistency at coupon level

- Prototype testing in real-life conditions

- Check repeatability/consistency at prototype level

- Reassessing feasibility (IP, competition technology,commercial)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- A method of producing high performance lithium titanate anode material for lithium ion battery applications” Indian Patent No. 365560 (granted) dated 28-04-2021, PCT International Application No. PCT/IN2018/050080; US Patent No.11001506 (granted) dated 11/05/2021; Germany Patent Application No. 112018000205 T5; Japan Patent No.7121734 (granted) dated 09-08-2022; Chinese Patent No. IIC190527 (granted) dated 01/12/2021; South Korea Patent No.03079 (granted) dated 29/12/2022.

Development of high performance C-LFP by cost-effective and scalable solid state process

Overview

As part of ATMANIRBHAR BHARAT for electric mobility, ARCI has developed an innovative and low-cost technology for the production of in-situ carbon modified Lithium Iron Phosphate (C-LFP) as a cathode material for Lithium-ion batteries. The technology was demonstrated on large scale (10 Kg/batch) successfully in collaboration with an Indian Powder Metallurgy Industry under public private partnership. The electrochemical performance of large scale synthesized C-LFP exhibits a capacity of 1.75 and 1.45 Ah at formation and 1C current rate respectively. ARCI has filed a patent application (202011056608) in India on 28th December 2020 and subsequently filed a PCT Application (PCT/IN2021/051138) on 6th December 2021. The Indian patent application now stands granted with the number 412586 dated 28th November 2022. The technology is already transferred to M/s. Allox Minerals Pvt. Ltd., Hyderabad on non-exclusive basis in India and is ready for transfer to other industries.

Key Features

- Single step solid-state synthesis process to produce carbon coated LiFePO4 (C-LFP) material.

- Simple, Scalable and Economical process.

- Tunable process to produce C-LFP with desired properties for various applications

- Electrochemical performance of C-LFP are at par with commercial C- LFP

Potential Applications

- High energy density cathode for electric vehicles

- High power density cathode for marine application

- Other portable devices where LIB s are used.

Technology Readiness Level (TRL):

- Performance was validated at pilot scale

- LIB cell prototypes were made and validated by third party

- Technology was transferred on non-exclusive basis

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

- Check repeatability/consistency at coupon level

- Prototype testing in real-life conditions

- Check repeatability/consistency at prototype level

- Reassessing feasibility (IP, competition technology,commercial)

- Initiate technology transfer

- Support in stabilizing production

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- Filed a patent application (202011056608) titled "Method of producing in-situ carbon coated lithium iron phosphate cathode material for lithium-ion batteries and the product thereof" in India on 28 th December 2020 and subsequently filed a PCT Application (PCT/IN2021/051138) on 6th December 2021. The Indian patent application now stands granted with the number 412586 dated 28 th November 2022; US Patent Application No. 18/254,730 dated 29 th May 2023; Australia Patent Application No. 2021412505 dated 1 st May 2023; Europe Patent Application No. 21914895.4 dated 9 th June 2023; UAE Patent Application No. P6001377/2023 dated 6 th June 2023.

Major Publications

Development of petcoke derived porous C for high performance supercapacitors

Overview

Super capacitors have been recognized as promising energy storage devices due to their fast charge-discharge time, very high power density and long life cycle period. It is commercially available but widespread usage is restricted by their high cost and low energy density. These drawbacks can be mitigated by developing a new class of high performance carbon electrodes which consist of a combination of materials produced from abundant, cheap and environmentally friendly resources with low processing costs. ARCI has developed graphene-like activated porous carbon by a low-cost chemical activation process using petroleum coke (petcoke), which is a great value addition for the waste disposed in large quantities in oil industry. The resulting carbon material delivers excellent super capacitor performance in terms of capacitance, rate capability and cyclic stability in comparison to

Key Features

- Facile synthesis of porous carbon by a simple chemical activation process

- Graphene like structured carbon, high surface area, large pore volume

- Conversion of abundant and waste petcoke into useful carbon material

- Specific capacitance, rate capability and cyclic stability higher than commercial carbon

- High energy density based supercapacitor

- Scalable manufacturing process

Potential Applications

- Automotive transport (E-rickshaw, electric bus, electric bicycles, electric cars) and drones

- Consumer electronics (power tools, voltage stabiliser, grid power buffer, street lamps)

- Energy recovery through regenerative braking systems (trams, cranes, tractors)

- Memory backup for static random-access memory (SRAM)

Technology Readiness Level (TRL):

- Successfully scaled-up (1kg/batch) of porous carbon from petcoke

- Fabricated supercapacitors of 1200 F and demonstrated on E-bicycle

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

- Check repeatability/consistency at coupon level

- Prototype testing in real-life conditions

- Check repeatability/consistency at prototype level

- Reassessing feasibility (IP, competition technology,commercial)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

Development of High Energy 1200F Supercapacitor using Petcoke Derived Porous Carbon

Overview

Petcoke-based 1200 F supercapacitor device has been developed using high performance porous activated carbon electrodes indigenously, which will be commercially attractive for Electric Vehicles (EVs) industry. The supercapacitor device with the specifications of 1200 F, 2.7 V and 1.2 Wh has been fabricated successfully from petcoke derived carbon. Electrochemical testing reveals that the performance of indigenous supercapacitor device is on par with the performance of world-class commercial supercapacitors (1200F). 16 numbers of 1200 F indigenous supercapacitors were connected in serial to assemble the module with specifications of 75 F, 43 V and 19.2 Wh for E-Bicycle demonstration with the driving range of 1-2 km.

Key Features

- High capacitance >1200F supercapacitor developed for the first time in India

- Novel Tab less welding technology adopted for the fabrication of high power supercapacitor

- Specific capacitance, rate capability and cyclic stability at par with commercial carbon

- Supercapacitor module of 43 V was made

- Designed voltage balancing circuit to control the voltage during

Potential Applications

- Automotive transport (E-rickshaw, electric bus, electric bicycles, electric cars) and drones

- Consumer electronics (power tools, voltage stabiliser, grid power buffer, street lamps)

- Energy recovery (trams, cranes, tractors)

- Memory backup for static random-access memory (SRAM)

Technology Readiness Level (TRL):

- Successfully fabricated indigenous supercapacitor with 1200F at par with commercial supercapacitor

- Assembled a supercap module and demonstrated for EVs application

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

- Check repeatability/consistency at coupon level

- Prototype testing in real-life conditions

- Check repeatability/consistency at prototype level

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- ranslational materials research - From laboratory to product: A 1200 F cylindrical supercapacitor from petroleum coke derived activated carbon sheets, Journal of Energy Storage 55 (2022) 10565.

- Petroleum coke as an efficient single source for High Energy and High Power Li-ion Capacitors” Energy & Fuels, 35, 9010-9016, 2021.

- A High-Energy Density Li-Ion Hybrid Capacitor Fabricated from Bio-Waste Derived Carbon Nanosheets

Major Publications

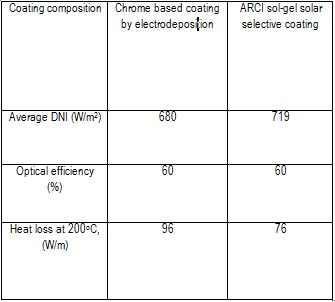

Solar Selective Coatings for Stainless Steel and Aluminium Substrates

Overview

Key Features

- 94 ± 1 % absorbance in 300-1500 nm range

- 14 ± 1 % Thermal IR emittance

- Withstood 20 cycles of thermal cycling at 350oC

- Withstood 80 h of salt spray test as per ASTM B117

- Non-toxic and environmental friendly

Potential Applications

- Solar selective coatings on absorber tubes of Concentrated Solar Power plant (Non-evacuated up to 250 deg C and evacuated up to 400 deg C)

- Solar selective coatings on metal tubes for water heating applications (up to 100 deg C)

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

- Scale-up and prototype testing completed

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- An improved composition for solar selective coatings on metallic surfaces and a process for its preparation and a process for coating using the compositions, Indian patent application number 3324/DEL/2011 dtd 22-11-11.

- R. Subasri, K.R.C. Soma Raju, D.S. Reddy, Neha Y. Hebalkar, G. Padmanabham, Sol-gel Derived Solar Selective Coatings on SS 321 Substrates for Solar Thermal Applications, Thin Solid Films 598 (2015) 46-53.

- Priya Anish Mathews, K.R.C. Soma Raju, Sanjay Bhardwaj and R. Subasri (2013): Sol-Gel Functional Coatings for Solar Thermal Applications: A Review of Recent Patent Literature, Recent Patents on Materials Science 6, 195-213.