Textiles

Scalable production of ultrathin graphene nanoplatelets

Overview

2-D graphene nanosheets, which is composed of one atom thick sp2 carbon network, shows great potential for industrial applications owing to their excellent electrical, thermal mechanical, electronic, chemical properties and high surface area. Preparation of graphene through exfoliation and fragmentation is one of the most effective methods to produce graphene-based conductive materials in a large quantity. The exfoliation through microwave irradiation is much more cost-effective than all other methods as it heats the materials uniformly and effectively. The graphite structures consist of layers of hexagonal carbon structures within which a chemical compound can be intercalated and is escaped due to thermal shock by creating large number of pores in worm-like structured exfoliated graphite. This unique process exhibited volume expansion of 300 % with extremely porous structure. Graphene nanoplatelets (GNP) shown specific surface area of 117 m2/g. As produced GNP are highly crystalline in nature with very limited defects. GNP preparation by microwave irradiation and shear mixing is a unique novel process for bulk production.

Key Features

- Very high aspect (width to thickness) ratio

- Majority of platelets are less than 10 nm thickness

- Compatible with almost all polymers

- Thermally and electrically conductive

- Contains naturally occurring functional groups like carboxyl and hydroxyl

- Scalable production process

Potential Applications

- Electrode for Supercapacitor

- Thermally conductive additive

- Electrically conductive additive

- Wear and friction modifier

- Additive for composite materials (polymer, metal and ceramic matrix)

- Anode material for metal-ion batteries (Li, Na and K)

Intellectual Property Development Indices (IPDI)

- Scalable quantity with tailored sizes

- Scale-up and prototype module has been established

- Demonstration of heavy-duty mixer-driven bulk production is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Self-cleaning Evaluation of Visible-light-driven Modified Titania for Textile Application

Overview

As part of visible-light active material developmental activity, highly visible light active photocatalysts, based on titanium dioxide nanostructure material containing carbon, C-TiO2 core-shell nanoparticles by an in-situ Lyothermal process has been synthesized for photo catalytic self cleaning applications. Self-cleaning property of visible light photocatalysts incorporated fabric has been evaluated for the decomposition of gas phase acetaldehyde (CH3CHO) under visible-light illumination. Neither decrease in the concentration of CH3CHO nor increase in the concentration of CO2 is observed with commercial TiO2. In contrast, complete decomposition of acetaldehyde observed for composite (TiO2 with carbon nanoparticles) incorporated fabric under the illumination of indoor and outdoor light. The application of developed visible light active material could be extended to paint applications for the removal of VOCs.

Key Features

- A method of producing highly visible light active photocatalysts, C-TiO2 core-shell nanoparticles by an in-situ Lyothermal process.

- Evaluation of photocatalytic self cleaning property of C-TiO2 incorporated textile fabric for decomposition of volatile organic compounds (gaseous acetaldehyde).

- Photocatalytic performances of C-TiO2 are on par with commercial visible-light driven photocatalysts for the decomposition of volatile organic compounds under UV, visible and solar light illumination

Potential Applications

- Self-cleaning Application (textile, paint) for the removal of volatile organic compounds

- Anti-bacterial (Hospital) application

Intellectual Property Development Indices (IPDI)

- Developed a simple, cost-effective and large scale process to synthesize visible-light active titanium dioxide nanostructure material containing carbon

- Successfully evaluated for evaluated prototype sample (C-TiO2 incorporated textile fabric) for self-cleaning photocatalytic decomposition of gaseous acetaldehyde.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Method of producing nanostructured C-TiO2 composite material for visible light active photocatalytic self-cleaning applications, Indian Patent Application No. 201811011478 dated 28th March, 2018.

- Efficient ZnO-based visible-light-driven photocatalyst for anti-bacterial applications” ACS Appl. Mater. Interf. 6, 13138-13148, 2014.

- Facile one step route for the development of in-situ co-catalyst modified Ti3+-self doped TiO2 for improved visible-light photocatalytic activity, ACS Appl. Mater. Interf. 8,27642-27653, 2016.

- Energy Level Matching for Efficient Charge Transfer in Ag Doped Ag Modified TiO2 for Enhanced Visible Light Photocatalytic Activity, J. Alloys and Compounds , 794, 662-671, 2019

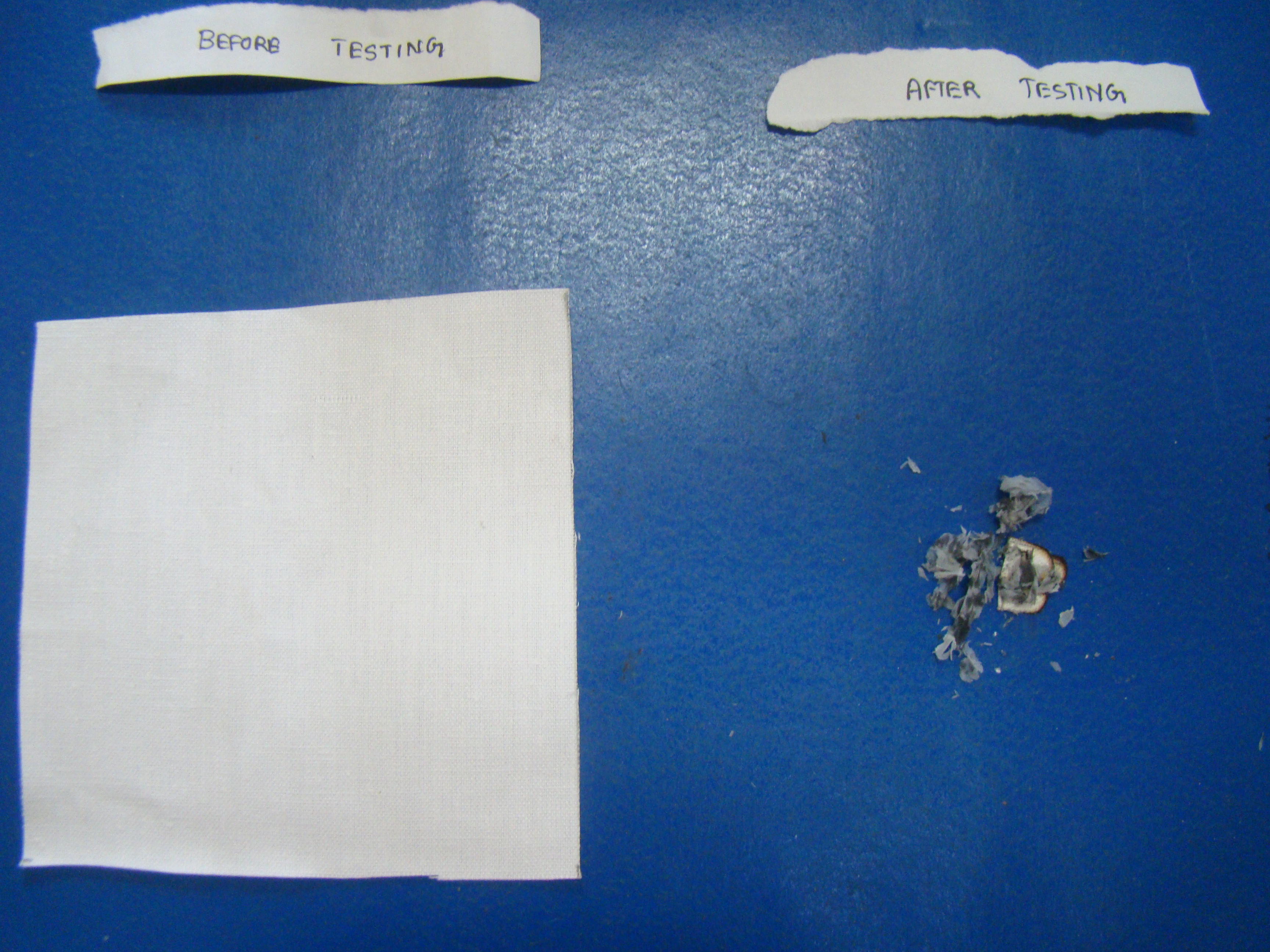

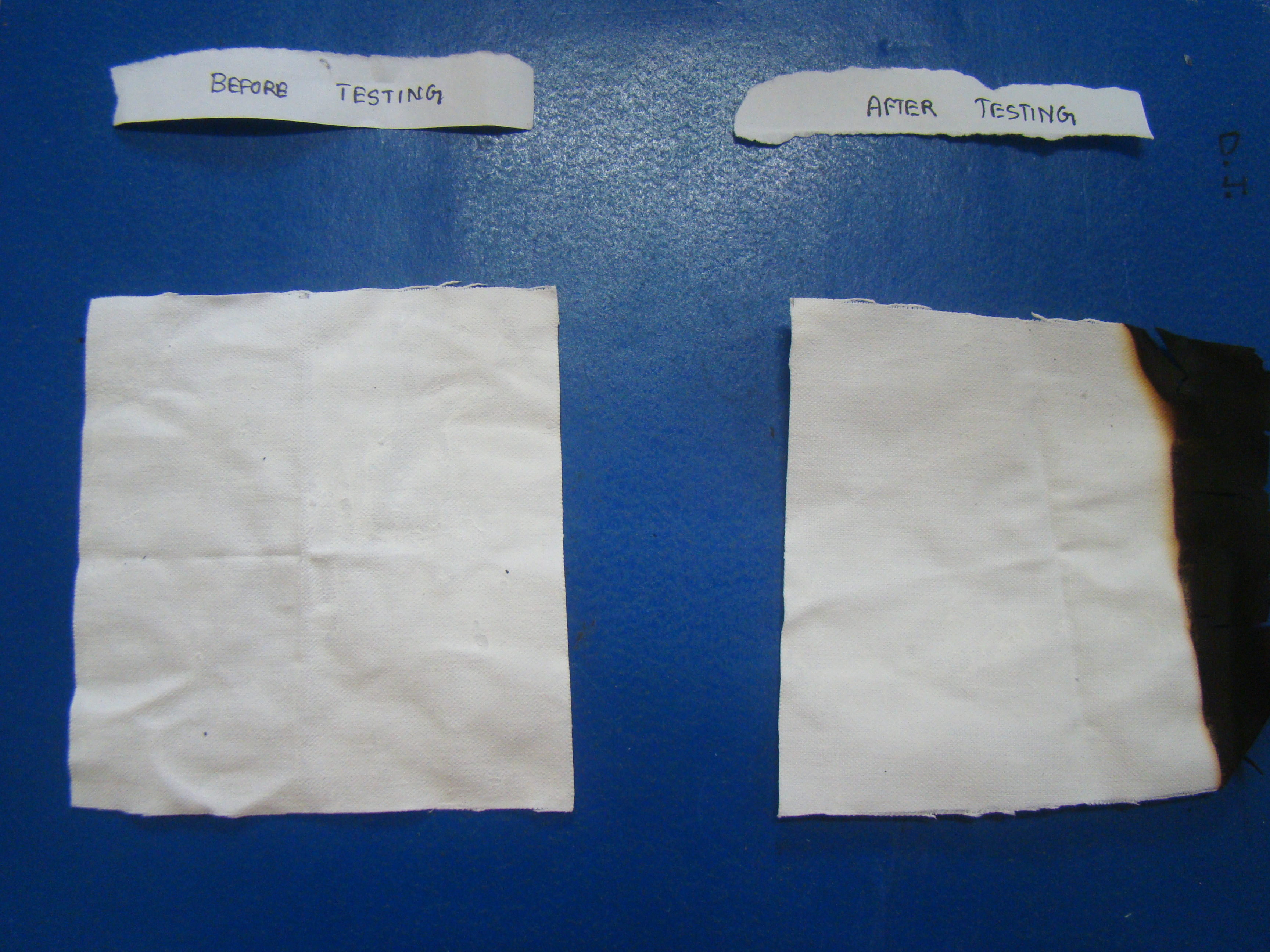

Flame Retardant Coatings on Fabrics

Overview

There has been a recent requirement of halogen-free flame retardant (FR) finish for textiles due to the toxic nature of halogenated flame retardant finish on fabrics. In addition, organic solvent based formulations have also come under scrutiny in recent years. Hence, water-based and halogen-free sol-gel composition is a basic requisite for synthesis of safe and eco-friendly flame retardant formulations for fabrics. The halogen-free, water-based sol-gel coating formulation developed by ARCI when deposited on fabrics was found to increase the limiting oxygen index, provide substantial flame retardant property after ignition and self-extinguishment of the flame even if ignited. The process uses nanoscaled metal oxide powders in conjunction with a sol-gel matrix, that can provide flame retardant property along with good adhesion to the fabrics.

Key Features

- Limiting oxygen index: 37.5 % for FR treated cotton vis-à-vis < 21% for untreated cotton

- FR treated fabric does not ignite or even if ignited, self-extinguishes after 2 sec

- Can be applied on cotton, nylon, polyester

- Simple methods like dipping or padding can be used for FR treatment

- Coatings can be cured very rapidly using Near Infrared (NIR) radiation

Potential Applications

- Curtains in Air Conditioned Compartments of Railway Coaches

- Curtains in Air Conditioned Buses

- Fire fighting Garments

- Laboratory Aprons

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up and prototype validation to be carried out

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- An Improved Coating Composition to Provide Flame Retardant Property to Fabrics and Process of Preparing the Same - to be filed shortly