Automotive

In-situ carbon coating technique for layered oxide cathode materials for Lithium ion battery

Overview

Uniform carbon coating on electrode materials for lithium ion battereis is an effective method to increase the cyclic stability of lithium ion cells. By a novel in situ technique of solid state reaction of carbon precursor pillared metal hydroxides having uniform carbon coating on oxide electrodes such as LiNi1-x-yCoxMnyO2, LiMn2-xN1-xO4, LiNi1-x-yCoxAlyO2, NaNi1-x-yCoxMnyO2, Li2MnO3: LiNi1-x-yCoxMnyO2 has been achieved. A improved cyclic stability of the uniform carbon coated cathode materials compared to that of bare materials for lithium ion battereis is demonstrated

Key Features

- Air ambient synthesis

- Insitu single step uniform carbon caoting

- Scalable manufacturing process

- Easily extendable to all oxide active material for Li/Na ion battereis

Potential Applications

- Lithium ion battereis

- Sodium ion batteries

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up synthesis is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- A process for in-situ carbon coating on alkali transition metal oxide, M. B. Sahana, S. Vasu, M. Sathiya, and R. Gopalan, Patent Application No. 201611007461, Date of filing: March 03, 2016.

- In-situ carbon encapsulation of LiNi1/3Co1/3Mn1/3O2 using pillared ethylene glycol trapped in the metal hydroxide interlayers for enhanced cyclic stability S Vasu, M. B Sahana, C Sudakar, R Gopalan, G Sundararajan Electrochimica Acta 251, 363-377

PEM Fuel cell powered materials handling devices

Overview

One of the major application domains that have emerged in recent years is the use PEM Fuel cells in materials handling devices such as forklifts. This industry is rapidly adopting fuel cells because of their life-cycle cost and productivity advantages over batteries. Hydrogen fuel cell-powered equipment needs refuelling once or twice daily, depending on use. Fuel cell provides consistent power strength during use and does not experience decreased performance unlike batteries which require battery change out or recharge time. The challenges include fabricating fuel cell stacks with high performance and small foot print/volume, developing a closed loop thermal management system to operate the fuel cell stacks for long duration, power electronic units which deliver constant voltage, and system integration and packaging so that the fuel cell system with all its BoP and hydrogen supply unit fits in the space available in the forklift.

Key Features

- Air cooled/ closed loop liquid cooled PEMFC stacks to be developed .

- PEMFC stacks with reduced weight and volume would be developed Control system development for the battery fuel cell hybrid system.

- PEMFC stack would operate optimum efficiency at variable operating loads.

Potential Applications

- Application in material handling devices like Forklifts

- Application in recreational vehicles like Go Karts, Golf- Carts etc.

- Power source for all mobile applications.

- Power source for auxiliary units in mobile applications.

Intellectual Property Development Indices (IPDI)

- Air cooled stacks of capacity 1kW developed.

- Liquid cooled stacks with close loop cooling developed for 5kW PEMFC power for vehicular applications

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- A Grid Independent Fuel Cell system with a unitized (Dc&AC) power conditioner, N.Rajalakshmi, K.Ramya, R.Balaji, S.Bharathi, K.Sanjeev, K.Ranjan,M.M.Ramakrishna,Indian Patent Application No: 201911006700

- Method of preparation of carbon supported platinum electrocatalyst for proton exchange membrane fuel cells, N.Rajalakshmi, Raman Vedarajan, J.A. Prithi, Patent Application no. 202011035825.

- K Hari Gopi, Ashwin Nambi, N Rajalakshmi, Design and development of open cathode PEM fuel cell - Flow analysis optimization by CFD, Fuel Cells 2020, 20, 33-39.

- A Device for and A Method of Cooling Fuel Cells, K.S.Dhathathreyan, N. Rajalakshmi, B. Viswanath Sasank , Indian Patent Application no. 1409/DEL/2012

- B.V. Sasank, N. Rajalakshmi and K.S. Dhathathreyan,"Design and Optimization of a Closed Two Loop Thermal Management Configuration for PEM Fuel Cell using Heat Transfer Modules", International Journal of Chemical Engineering and Applications, Vol. 3( 3), p 243-248, 2012.

- K. S. Dhathathreyan, N. Rajalakshmi, K. Jeyakumar and S. Pandiyan, "Forced Air Breathing PEMFC Stack", International Journal of Electrochemistry, Vol. 2012, Article ID 216494, 2012, doi:10.1155/2012/216494, 2012

Fe- based cerametallic friction pads for clutch plates of heavy vehicles

Overview

Sintered Fe-Cu based cerametallic friction materials/pads for clutch and brakes of commercial heavy vehicles likes trucks and tractors are presently being imported. These friction pads are rivetted to steel back plates and fixed to the carrier plates before assembling in the clutch housing. The life of the friction pad is limited to the depth of the rivet limiting 100 % utilisation of the friction material/pad and with usage, the failure is initiated along the rivet hole. Further, rigid bonding introduces a little discomfort arising out of judder while driving. Thus, the project involves innovative methods of replacing riveted clutch buttons with bonding of friction cookies directly onto the clutch plate, dispensing with the requirement of the additional steel back plate. A patented technology with reduced number of process steps with compositional change and indigenous equipment design has been developed to increase driving comfort along with increased life of clutch system.

Key Features

- Use of non carcinogenic materials

- Improved wear and coefficient of friction constantly higher than slip coefficient

- Fe-based sintered pad

- Flexibility of single or dual sintered friction pads

- Indigenous equipment for processing

- Reduced post sintering operations

- Production level manufacturing process

Potential Applications

- Clutch and brakes of heavy commercial vehicles

- Aircraft brakes

- Passenger vehicles like buses

- Wind mill applications

- Railways

- Military tanks

Technology Readiness Level (TRL):

- Performance and stability are validated at laboratory scale

- Prototype level demonstrated

- Scale up design of equipment and technology available

Intellectual Property Development Indices (IPDI)

- Basic concepts and understanding of underlying scientific principles

- Short listing possible applications

- Research to prove technical feasibility for targeted application

- Coupon level testing in stimulated conditions

- Check repeatability/ consistency at coupon level

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- Malobika. K and A. Siva Kumar, ‘Multi Piston Hot Press for Producing Powder Metallurgy Components by sintering the green-powder Metallurgy Compacts”, application no. 3844/DEL/2011, dtd. 28.12.2011, grant no. 379250 dtd. 13/10/2021

Major Publications

Aqueous based gel casting process for the development of near net shape non-oxide ceramic product

Overview

Gel casting is a near net shape colloidal processing technique for ceramics which can be adapted to develop ceramic products having various size and shapes. This technique offers advantages of machining intricate shape ceramic parts in green condition. It is possible to tailor the properties of ceramics in terms of density, mechanical properties by tailoring the composition and processing parameters. ARCI has developed SiC, Si3N4 and SiAlON products in prototype scale with the help of gel casting process and successfully sintered the products without any warpage or defect.

Key Features

- Near-net processing of complex shapes.

- Green machining

- Scalable to large size.

- Cost effective.

Potential Applications

- Non-oxide based crucibles for metallurgical industry.

- Electromagnetic windows.

- Cellular SiC product for solar receiver applications.

Intellectual Property Development Indices (IPDI)

- Up-scaling is in progress for large size products.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- P. Barick, D.C. Jana and B.P. Saha, Load-dependent indentation behaviour of βSiAlON and αSilicon carbide, J. Adv. Ceram. 2, (2013), 185192.

- D. C. Jana, G. Sundararajan and K. Chattopadhyay, Effect of monomers content in enhancing solid-state densification of silicon carbide ceramics by aqueous gelcasting and pressureless sintering, Ceram. Inter., 43 (2017), 4852-4857.

- K. M. Reddy and B. P. Saha, Microstructure-property correlation of porous β-SiAlON ceramics, J. Alloy. Comp., 779 (2019), 590-598.

Nanoscaled-carbon hybrids for gas and organic vapor detection

Overview

Research activities in area of chemiresistors used in gas sensing is rising due to the demand for cost effective, fast response and sensitive sensors which are vital in detecting hazardous and harmful gases such as greenhouse gases, organic vapor and other gases produced by combustion of fossil fuels, power plants and automobiles etc. In such needs, nanoparticles serve as building blocks as they have very high aspect ratio combined with large surface area which is favourable for adsorption of gaseous analytes over them. Particularly, the advent of nanoscaled-carbon fuelled the invention of gas sensors that exploit unique geometry (tubular, spherical and sheet-like) and material properties. The electrical conductivity of nanocarbon (carbon nanotubes, carbon onion and graphene) is much higher in comparison with metal oxides and sulphides. The formation of heterojunctions (p-n) in nanocarbon-metal oxide/sulfide or conducting polymer hybrid lead to enhanced gas sensitivity of such hybridized gas sensor as the decrease in work function of the metal oxide/sulphide sensitive layer lead to improvement in performance of chemiresistor at low operating temperatures.

Key Features

- n-type metal oxide-anchored nanocarbon hybrids

- Surface modified carbon nanomaterials for gas selectivity

- Various kinds of metal oxides with tuneable bandgap

- Facile route to coat metal oxide on carbon nanomaterials

- Fast sensing characteristics

Potential Applications

- Gas sensing

- Organic vapor detection

- Automobile exhaust analysis

- Environment diagnosis

- Coal mine area monitoring

- Drainage lines monitoring

Intellectual Property Development Indices (IPDI)

- Preparation metal oxide anchored carbon nanomaterials

- Organic vapor sensing characteristics evaluated

- Development of sensor to detect organic vapor is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Layered two-dimensional graphene nanosheets for nanolubrication

Overview

Lubrication has been an area of extensive research in search to achieve the conditions of a super lubricant i.e. zero friction. Among all approaches, engine friction reduction is a key and relatively cost-effective approach, which has been receiving significant attention from tribologists. However, a large amount of fuel energy is still lost in overcoming friction even after many revolutions in this sector. Carbon nano-additives have the potential to be the replacement to present day additives and give improved results. The quantity of additives in the dispersion is less than the commercial additives by a magnitude of 25-27%. Tribological studies with few layered graphene in an engine oil suspension showed comparable results with the commercial oil. Significant reduction in wear rate and friction was observed for lubricant with graphene nanoplatelets additives. Tests at elevated temperatures at 75°C, with high load and speed of rotation showed similar results of reduction in wear and friction coefficient. The Few-layer graphene nanosheets loaded in a base oil forms thin films over a mating surfaces to minimize the friction-induced effects and can act as thermal conductivity enhancer to transfer heat effectively.

Key Features

- Various kinds of nanostructured carbon materials

- Microwave irradiation for rapid synthesis

- Surfactant-free dispersion in oil

- Minimum quantity lubrication is focused in terms of additive concentration

- Scalable manufacturing process

- Homogeneous dispersion

- Stability for long duration

Potential Applications

- Engine oils for automobiles

- Regenerative braking system

- As grease additives in high load bearing joints

- Thermal property enhancer in radiator coolants

- Non-corrosive coatings for bottle neck joints

Intellectual Property Development Indices (IPDI)

- Rheological properties with better stability achieved

- Wear and friction characteristics are validated at laboratory scale

- Application oriented tests on related materials is to be followed up using raw base oil

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Technology of Easy to Clean Coating

Overview

Self-clean (easy to clean) technology is generally related to protect the solar devices from dust/dirt, corrosion and all sorts of weather conditions. PV panels are very important solar devices traditionally mounted outdoors on rooftops or in wide open spaces where they can maximize their exposure to sunlight. Unfortunately, this type of outdoor placement of the devises is subjected to substantially constant weather and moisture exposure. Due to this constant and extended exposure to the devices are preferably designed for using many years of stable and reliable operation without failure due to moisture damage. A general challenge is finding one protective coating (single layer) that has best-in-class qualities of selfclean property (easy to clean property), high weather and mechanical stabilities, no loss in transmittance/power conversion efficiency after deposition on PV panels and curable by ambient conditions. ARCI’s new technology will provide solution for the above-mentioned issues.

Key Features

- Low cost production (simple coating technique / easy scalable / curable by ambient temp.)

- Highly transparent coating (no loss in transmittance / power conversion efficiency after deposition)

- Super hydrophobic property: > 110 0 water contact angle

- High weather stability (withstand long duration accelerated test (IEC 61646)

- High mechanical stability

- Low dust deposition compared to bare and other commercial coated samples

Potential Applications

- PV panels & reflectors employed in CSP

- Optical lenses

- Video display panels

- Architectural glasses

- Textiles

- Plastic & concrete surfaces

- Ceramic tiles

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Indian patent Application no. 402/DEL/2014, date of filling: 13.02.2014.

- Indian patent Application no. 201911009429, date of filling: 11.03.2019.

Dual Functional Antireflective and Antifogging Coating Technology

Overview

Dual Functional (Anti-Reflective & Anti-Fogging) coatings are important for transparent materials. Anti-fogging and Antireflective coatings are now often used on transparent glass or plastic surfaces used in optical applications, such as the lenses and mirrors found in glasses, goggles, camera lenses, and binoculars. These functional coatings attracted a great attention. Dual functional coating (Antireflective with Anti-fogging properties) with high optical transmittance (> 96% on glass; >94% on optical lens), and high weather stability (> 100 h Environmental chamber test) has been successfully developed. It exhibits high super hydrophilic property < 5o or any other type of devices that require minimal reflection.

Key Features

- High transmittance (>95 %)

- Low temperature curable (<100 °C)

- Weather stable (withstands humidity > 90 %)

- Highly mechanical stable and Long durability

- Highly Super-hydrophilic (Contact Angle < 5°)

Potential Applications

- Solar PV & CSP cover glass

- Optical lenses

- Video display panels

- Architectural glasses

- Automobile window shields

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Indian patent application no. 2919/DEL/2013, date of filling: 3.10.2013.

Community solar parking lot based on perovskite solar roof

Overview

Themost promising technology for conversion of solar energy into electricity (renewable energy generation) and most widely commercialized technology include silicon (Si) solar technology, where recent advancements offers low manufacturing costs. Though Si photovoltaic technology has its high ground processing cost and difficult in manufacturing is still a bottleneck. To overwhelm the difficulty lot more alternative materials were fabricated and tested for better conversion efficiency. Among all 3rd generation organic-inorganic metal halide perovskite solar cells(PSCs) shown promising results with high power conversion efficiency (PCE), ease of fabrication cost with effortless fabrication techniques.Initial experiments started with a lab scale (15mm × 15mm PSC device dimension) conventional PSC device fabrication with the PCE of 16.2% as shown in Fig.1(a & b).

Key Features

- Tunable band gap and visible light transmittance

- Ease of fabrication process

- Non- vaccum based fabrication process

Potential Applications

- Automobile (auxiliary power generation)

- Off-grid power generation

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Glass-to-glass encapsulation with ultraviolet light curable epoxy edge sealing for stable perovskite solar cells, Materials Letters, 250 (2019) 51–54.

- Hole-conductor free ambient processed mixed halide perovskite solar cells, Materials Letters, 245 (2019) 226-229.

Glass based sealant for SOFC application

Overview

Solid oxide fuel cells (SOFCs) are used for a wide range of applications including power generation, automobile etc. Planar SOFC configurations appear superior to other form, like tubular based onsuperior power density and efficiency. A major issue in planar SOFCs is the requirement that hermetic sealing must be formed between the solid electrolyte and/or the ceramic anode with the metallic interconnect in order to prevent fuel - oxidant mixing and to provide electrical insulation. The wide range of thermal expansion characteristics and the thermal stability advantages of glass based sealant (or glass-ceramics) are important factors in sealing. To ascertainacceptable lifetime, interfacial reactions and diffusion of both metallic and glass species should be minimized. Glass based sealant capable to form rigid seal between the interconnect and other SOFC parts, which in turn reduce the leak rate within acceptable limit.

Key Features

- Tuneable compositions and properties (e.g. CTE, resistance to reaction with adjacent part).

- Wide range of glass compositions for suitability as sealant

- Simplicity in makingglass frits, powders and subsequently sealing paste.

- Compatibility with the SOFC stack components such as cathode, anode and interconnect

- Application temperature: 800-8500c

- Ability to self-heal the crack (if any) in seal during operation

Potential Applications

- Sealant for SOFC stack.

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

High performance silicon carbide (SiC) tubes

Overview

SiC tubes have emerged as potential candidate material in the area of concentrated solar power generation, heat exchangers for recovery of heat from industrial waste, fuel cladding in nuclear reactors because of superior thermos-mechanical properties, high thermal conductivity, resistance to chemical attack and nuclear radiation. ARCI has developed the process for producing SiC tube by extrusion as well as cold iso-static pressing technique followed by sintering.

Key Features

- Extrusion press is capable of producing long tubes of different diameter and wall thickness.

- High production rate.

- Process flexibility to produce dense and porous SiC tubes.

Potential Applications

- Tubular solar receiver in CSP technology.

- Heat exchanger.

- Nuclear fuel cladding tubes.

- Support tubes in membrane separation.

Intellectual Property Development Indices (IPDI)

- SiC tubes produced by both extrusion and cold-isostatic pressing have been produced and properties tubes are being evaluated.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- S. Mubina, A. K. Khanra and B. P. Saha, Processing of sintered and CVD coated SiC/CNFs thin composite tubes, Mater. Chem. Phys., 220 (2018), 225-232.

- S. Mubina, M. Ilaiyaraja, A.K. Khanra, B. P. Saha, Fabrication and microstructure analysis of continuous C fibers reinforced SiC-CNTs hybrid composite tubes, Materials and Manufacturing Processes, 36 (2021) 292-300.

- S. Mubina, P. S. Phani, A. K. Khanra, B. P. Saha, A nanoindentation based study to evaluate the effect of carbon nanofibers on the mechanical properties of SiC composites, Journal of Composite Interfaces, 2020, 1-18, DOI: 10.1080/09276440.2020.1780555

- S. Mubina, A. Khanra, B. P. Saha, Enhancement of oxidation resistance of CVD SiC coated Cf/C-SiC hybrid composite tubes processed through Si-infiltration, Journal of Alloys and Compounds, Journal of Alloys and Compounds, volume 826. 154107,DOI:10.1016/j.jallcom.2020.154107.

- S.Mubina, A. Khanra, B. P. Saha, Optimization of processing parameters, physical and mechanical properties of SiC – CNF composites using Taguchi approach, Material Today Proceedings, 18 (2019) 75300-5308

Ready-to-press and sinterablenon-oxide ceramic granules

Overview

Ready-to-press non oxide ceramic granules such as silicon carbide (SiC) and SiAlON are being produced using spray drying or spray freeze drying technique through an intermediate colloidal processing route. This method is capable of producing different size spherical granules with narrow size distribution and improved flow characteristics. As the granules are produced from uniformly dispersed slurries of SiC or Si3N4-based composite powders, hence wide range of additives can be accommodated in the formulation of the RTP granules. This process is beneficial to manufacture the feedstock for producing green non oxide ceramic compacts with high density, defect free homogenous microstructure. The sintered products thus produced exhibit superior properties than conventionally produced powders. The technique has been adapted to produce RTP granules comprising water sensitive nitride based composite powders.

Key Features

- Cost effective technique to produce RTP SiC granules.

- Flexibility to incorporate either solid-state or liquid-phase sintering additives in the formulation of RTP granules.

- Control on granule size with narrow distribution

- The process can be adopted for manufacturing various oxide or non-oxide ceramics.

- Up to 97.8 % relative density achieved in the sintered parts.

Potential Applications

- Feedstock for manufacturing of high performance SiC, Si3N4, SiAlON components

Intellectual Property Development Indices (IPDI)

- RTP granules processed in the laboratory scale

- Scaling up the process isin progress

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- P. Barick, B. P. Saha, S. V. Joshi and R. Mitra, Spray-freeze-dried nano-crystalline SiC containing granules: processing, compaction behaviour and sintering, J. Euro. Ceram. Soc., 36 (2016), 3863-3877.

- P. Barick, B.V. Shalini, M. Srinivas, D. C. Jana, and B. P. Saha, A facile route for producing spherical granules comprising water reactive aluminium nitride added composite powders, Adv. Powder Technol., 31 (2020) 2119-2127.

Dense silicon carbide (SiC) coatings by chemical vapour deposition (CVD) technique

Overview

Theoretically dense SiC coating processed by chemical vapour deposition (CVD) exhibits superior physical, mechanical, thermaland optical properties with excellent wear, abrasion and chemical corrosion resistance. The properties of CVD SiC coating can be tailored by control of various parameters including reactor design, process temperature, pressure, reactants composition and flow geometry. ARCI has established a CVDsystem for coating of large size components (up to 1.0 m meter)by thermal deposition of methyl-trichlorosilane (MTS) in excess of hydrogen.High density CVD SiC coating onvarious substrates with different geometries have been produced. It has been demonstrated that the CVD SiC coating can be polished up to the RMS surface roughness < 1 nm. ARCI also has the capability to produce self-standing CVD SiC parts.

Key Features

- State-of-the art CVD SiC coating facility.

- The processes technology has been established

- SiC coating on different size and shapes can be produced.

- CVD SiC coating can be polished to very high surface finish (<1 nm).

Potential Applications

- Reflectors for high energy laser and synchrotron radiation.

- Wear and corrosion resistant coatings

- Reflectors for concentrated solar power (CSP) applications

- Solar collectors and concentrators for astronomical telescopes.

Intellectual Property Development Indices (IPDI)

- The process technology and repeatability have been established.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- D. C. Jana and B. P Saha, Silicon carbide-based lightweight mirror blanks for space optics applications. In: Y. Mahajan and R. Johnson (Eds) Handbook of Advanced Ceramics and Composites, First Edition, Springer Nature Switzerland AG, 2020, pp. 1135-1163.

Sintered silicon carbide (SiC)components

Overview

Silicon carbide (SiC) is one of the most attractive ceramic materials because of its excellent mechanical properties such as high strength, moderate toughness, and high wear and oxidation resistance, and strength retention at elevated temperature. ARCI has the expertise to manufacture SiC parts with various size and shapes by pressureless sintering using solid-state or liquid phase sintering additives and also by hot pressing technique. SiC parts of complex geometry can also be manufactured through machining at the green stage using 5-axis CNC machine. Dimensional accuracy can also be achieved on sintered SiC parts by final shaping with the help of sophisticated ultrasonic machining.

Key Features

- Tuneable density and other thermo-mechanical properties.

- Flexibility in producing SiC parts incorporating solid-state or liquid phase sintering additives.

- Capable to produce SiC components up to 750 mm diameter.

- SiC parts with critical can be manufactured.

Potential Applications

- Mechanical seals particularly for corrosive environment.

- Impact and abrasion resistance parts.

- Light-weight structural parts for aerospace applications.

- Impact and wear resistant parts.

Intellectual Property Development Indices (IPDI)

- The technology has been validated for production of various size and shape SiC parts by pressureless sintering and available for technology transfer.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- P. Barick, D. C. Jana and B.P. Saha, Load-dependent indentation behaviour of βSiAlON and α Silicon carbide, Journal of Advanced Ceramics, 2, (2013), 185192.

- S. V. A. Raj, D. C. Jana, P. Barick and B. P. Saha, Microstructure Evolution in Densification of SiC Ceramics by Aluminium Vapour Infiltration and Investigation of Mechanical Properties, Ceram. Inter., 44 (2018), 9221-9226

- D. C. Jana, P. Barick and B. P. Saha, Effect of Sintering Temperature on Density and Mechanical Properties of Solid-State Sintered Silicon Carbide Ceramics and Evaluation of Failure Origin, J. Mater. Eng. Perform.,27 (2018), 2960-2966.

- D. C. Jana,G. Sundararajan and K. Chattopadhyay, Effective activation energy for the solid-state sintering of silicon carbide ceramics, Met. Mater. Trans. A, Vol 49 A (2018), 5599-5606.

Development of Lithium-ion Batteries for Electric Vehicle Application

Overview

Due to the depletion of the fossil energy reserves as well as alarming level of greenhouse gas emission triggered to look out for alternative clean energy sources, especially for automotive sector. The key challenge for electric vehicles is to get suitable battery to store the required amount of energy in a given volume for long driving range and speed. Lithium-ion battery (LIB) has been proven to be next generation technology to alleviate these problems. However, currently there are no manufacturers of these batteries in India. ARCI has undertaken a major task to developed LIB technology for electric vehicles by setting up a pilot plant facility for manufacturing of Lithium-ion cells and battery packs for automotive application. The objective is to establish the LIB technology using standard materials and demonstrate off-line/on-board vehicle testing. In addition high voltage/new materials will be developed indigenously. The promising materials will be optimized and scale-up for process technology.

Key Features

- ARCI has successfully fabricated prismatic/cylindrical cells (up to 20 Ah) and LIB module up to 48V, 1 kWh

- A fast cell formation protocol (6h) was developed and patented which is anticipated to reduce the cell production cost

- On-road test trails have been conducted with e-cycle (~30 km/charge) and e-scooter (~52 km/charge) using the LIB modules

- ARCI is developing several cathodes, anodes, and binder materials that could increase the performance and lifetime of LIBs for EVs. The cathode materials include LFP, NMC, NCA, LMO, LNMO, FeF3 whereas high energy/power density anodes include Si, Sn, MoO3, WO3, SnO2, Fe3O4, graphene, carbon nanohorns/nanotubes.

- Development of aqueous binders such as PVA, SA, CCD, guar gum for green and cost-efficient electrode production is underway

- Scaled up LiFePO4 by FSP process and scale-up of carbon coating technology up to 1.5 kg

- Lithium titanate was successfully synthesized and up-scaled by cost-effective high energy milling method and showed promising electrochemical performance in terms of capacity, rate capability and cyclic stability in comparison with commercial LTO.

- ARCI has signed several NDA and MOUs with potential cell manufacturers, automotive and raw materials manufacturing industries to produce Made-in-India LIBs.

Potential Applications

- Two, three and four wheeler electric vehicles

- Stationary energy storage applications

- UPS

Intellectual Property Development Indices (IPDI)

- Cells have been fabricated and electrochemical performance has been tested

- Assembly and testing of large format battery module/pack carried out with e-cycle and e-scooter under on-road conditions.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- S.R. Sahu, V.R. Rikka, P. Haridoss, A. Chatterjee, R. Gopalan and R. Prakash, " A Novel α-MoO3/Single-Walled Carbon Nanohorns Composite as High-Performance Anode Material for Fast-Charging Lithium-Ion Battery", Advanced Energy Materials, Vol 10, p 2001627, 2020

- S. R. Sahu, V.R. Rikka, P. Haridoss, R. Gopalan and R. Prakash, “Superior cycling and rate performance of micron-sized tin using aqueous-based binder as a sustainable anode for lithium-ion batteries”, Energy Technology, Vol. 7(11), Article No. 1900849, 2019

- V.R. Rikka, S.R. Sahu, A. Roy, S.N. Jana, D. Sivaprahasam, R.Prakash, R. Gopalan, and G. Sundararajan, “Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance”, Journal of Manufacturing Processes, Vol. 49, p 463-471, 2020.

- V. Rao Rikka, S. R, Sahu, R. Tadepalli, R. Bathe, T. Mohan, R. Prakash, G. Padmanabham and R. Gopalan, "Microstructure and mechanical properties of pulse laser welded SS and Al Alloys for lithium-Ion cell casings", Journal of Materials Science and Engineering B, 6, 2016, 218-225.

- R. Vallabha Rao, S.R. Sahu, P.V. Satyam, R. Prakash, M.S. Ramachandra Rao , R. Gopalan and G. Sundararajan, "In Situ/ex Situ Investigations on the Formation of the Mosaic Solid Electrolyte Interface Layer on Graphite Anode for Lithium-Ion Batteries", Journal of Physical Chemistry C Vol.122 (50), p 28717-28726 , 2018

- S.R. Sahu, V.R. Rikka, M. Jagannatham, P. Haridoss, A. Chatterjee, R. Gopalan and R. Prakash, "Synthesis of Graphene Sheets from Single Walled Carbon Nanohorns: Novel Conversion from Cone to Sheet Morphology", Materials Research Express, Vol. 4(3), Article No. 035008, 2017.

- S. Bhubaneswari, UV Varadaraju, R. Gopalan and R. Prakash “Sc-doping induced cation-disorder in LiNi0.5Mn1.5O4 spinel leading to improved electrochemical performance as cathode in lithium ion batteries”, Electrochimica Acta, Vol.327, Article No. 135008, 2019.

- S. Bhuvaneswari, U.V.Varadaraju, R.Gopalan and RajuPrakash, "Structural stability and superior electrochemical performance of Sc-doped LiMn2O4 spinel as cathode for lithium ion batteries", Electrochimica Acta, Vol. 301, p 342-351, 2019.

- Comprehensive effort on electrode slurry preparation for better electrochemical performance of LiFePO4 battery Kumari Konda, Sahana B. Moodakare, P. Logesh Kumar, Manjusha Battabyal, Jyoti R. Seth, Vinay A. Juvekar, Raghavan Gopalan, Journal of power sources, 480 (2020) 228837

- V. V. N. Phanikumar, Vallabha Rao Rikka, Bijoy Das, Raghavan Gopalan, B. V. Appa Rao and Raju Prakash, "Investigation on polyvinyl alcohol and sodium alginate as aqueous binders for lithium-titanium oxide anode in lithium-ion batteries, Ionics, 2019, Volume 25, Issue 6, pp 2549–2561.

- V. V. N. Phanikumar, B. V. A. Rao, K. V. Gobi, R. Gopalan and R. Prakash, “A sustainable tamarind kernel powder based aqueous binder for graphite anode in lithium-ion batteries”, vol 5, p 1199-1208, 2020

- Concentration Gradient-Driven Aluminum Diffusion in a Single-Step Coprecipitation of a Compositionally Graded Precursor for LiNi0.8Co0.135Al0.065O2 with Mitigated Irreversibility of H2 ↔ H3 Phase Transition, Sasikala Natarajan, Sahana B. Moodakare, Prathap Haridoss and Raghavan Gopalan, ACS Appl. Mater. Interfaces 2020, 12, 31, 34959–34970

- S. Vasu, Moodakare B. Sahana, Chandran Sudakar, R. Gopalan, G. Sundararajan, "In-situ carbon encapsulation of LiNi1/3Co1/3Mn1/3O2 using pillared ethylene glycol trapped in the metal hydroxide interlayers for enhanced cyclic stability," Electrochimica Acta 251, 363-377.

- Sasikala Natarajan, Sahana B. Moodakare, Vasu Shanmugam, Prathap Haridoss, and Raghavan Gopalan, "Infrared Spectroscopic signatures of Aluminium segregation and Partial Oxygen substitution by Sulphur in LiNi0.8Co0.15Al0.05O2", ACS Appl. Energy Materials, Vol. 1(6), p 2536-2545, 2018.

- S. R. Sahu, D. Parimala Devi, V. V. N. Phanikumar, T. Ramesh, N. Rajalakshmi, G. Praveena, R. Prakash, B. Das, R. Gopalan, "Tamarind seed skin derived fibre-like carbon nanostructures as novel anode material for lithium-ion battery", Ionics , volume 24, Issue 11, pp 3413–3421.

New soft magnetic steel alternate to Si-steel

Overview

Soft magnetic steel forms an essential component in all motors and alternators used in the automotive industry. Currently for high efficient motors Si steel (typical Si content ~2%) is being used. The ever increasing demand to phase out fossil fuel automotives and move to electric driven vehicles requires high performance motors. Hence there is a focus on alternate soft magnetic material which is cost effective and with better magnetic properties compared to Si steel. In this background we propose Fe-P as a potential alternate which is cost effective and with magnetic properties equivalent/better than Si steel. Fe-P based alloy prepared by wrought metallurgy process of induction melting, forging, hot rolling and subjected to a suitable two step heat treatment process yield soft magnetic materials with properties equivalent or better than Si steel. The formation of fine nano-precipitates of Fe3P enhances the resistivity of the alloy lowering the core loss at high frequency. Currently we have developed alloys with coercivity less than 1 Oe and a core loss of 187 W/kg at 1 kHz measured at Bmax 1 T

Key Features

- Industrially viable wrought metallurgy process

- Alloy produced from low cost raw materials (cost effectiveness)

- Better mechanical properties advantages of machinability

- Good magnetic properties equivalent/better than commercial materials

Potential Applications

- Used in alternators of automobiles

- Used in manufacture of various motors used in automobiles

- Explored for applications involving magnetic switching in valves and switch gears.

Intellectual Property Development Indices (IPDI)

- Magnetic properties measured and benchmarked with standard commercial materials

- Prototypes produced and being benchmarked with commercially used machines

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

Major Publications

- Effect of Si addition on AC and DC magnetic properties of (Fe-P)-Si alloy, AIP Advances 6, 055921 (2016)

- AC magnetic properties and core loss behaviour of FeP soft magnetic sheets, IEEE Transactions on Magnetics 50 (2014) 2008604

- High saturation magnetization in Fe-0.4 wt.% P alloy processed by a two-step heat treatment Journal of Magnetism and Magnetic Materials 345 (2013) 239.

- Effect of recovery and recrystallization on microstructure and magnetic properties of Fe-0.4 P rolled sheets, Materialia 13 (2020) 100863

- Influence of nanoprecipitates, solid solution and grain size on the magnetic and electrical properties of Fe-P-Si alloys, Journal of Magnetism and Magnetic Materials 493 (2020) 165743

Waste Heat Recovery using Thermoelectric modules

Overview

Conversion of heat generated and let out in atmosphere in various industrial processes to electricity have the dual benefit of improving environment by decreasing greenhouse gas emission and higher system efficiency. Thermoelectric (TE) technology is one of the most reliable method for converting such wasted heat into electric energy free from any pollution and noise making moving parts. Automotive exhaust waste heat conversion is one application extensively researched by many automobile manufacturers as the world is currently facing numerous problems due to the increasing demand in energy for sustainable transportation. It is calculated that 33% of total fuel energy in automobiles is wasted as exhaust gas. Hence TE technology can play a vital role in automobiles by converting the waste heat into electricity. Converting the waste heat generated from steel, cement, glass industries are some of the other applications being developed. Utilizing the heat from solar panel, concentrated solar thermal heat to power by thermoelectric are some of the other applications being explored.

Key Features

- Scalable inorganic thermoelectric materials technology to fabricate P and N type bulk solids with ZT more than 1.5 and chemically and structurally stable up to 500°C.

- Fabrications know how for making thermoelectric modules from the ZT > 1.5 materials. Developed and patented. Ready for upscaling.

- Demonstration of TE generator technology with more than 5 % efficiency to convert heat from various sources. TEG design, validation, performance testing, field trials.

Potential Applications

- Electricity from diesel engine exhaust heat in automobiles, community incinerators and solar thermic fluid.

- Power generation from steel plant, glass melting plant waste heat.

- Power from domestic heat source like wood stove.

Intellectual Property Development Indices (IPDI)

- Scalable inorganic thermoelectric materials with figure of merit (ZT) 1.3 and abobe

- Thermoelectric modules fabrication technology (TRL 5 level), Patent Filed

- Thermoelectric generator (TEG) technology for various applications (TRL 5 level) e.g. Automobile, steel industries.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- D.Sivaprahasam, B.Jayachandren, B.Prashant, R.Gopalan, “A method of preparing the thermoelectric module for power generation from automotive exhaust and the thermoelectric module thereof” Indian Patent filed

Major Publications

- M.Battabyal, B.Priyadarshini, D.Sivaprahasam, R. Gopalan, 2015. “Effect of Cu2O nanoparticle dispersion on thermoelectricproperties of n-type skutteudites”, J of Phys. D: Appl.Phys. 48, 455309. (2015)

- S.Harish, D.Sivaprahasam, M.Battabyal, R.Gopalan, 2016, “Phase stability and thermoelectric properties of Cu10.5Zn1.5Sb4S13 tetrahedrites” J of Alloys and Compound” 667, (2016) Pp. 323-328.

- B.Priyadarshni, M.Battabyal, D.Sivaprahasam, R.Gopalan, “On the formation of phases and their influence on the thermal stability and thermoelectric properties of nanostructured zinc antimonide”, J of Phys. D: Appl.Phys. 50, 015602. (2017)

- V Trivedi, M Battabyal, P Balasubramaniam, GM Muralikrishna, PK Jain, Microstructure and doping effect on the enhancement of thermoelectric properties in Ni doped Dy filled CoSb3 skutterudites, Sustainabale Energy & Fuels 2, (2018) 2687.

- M.Battabyal, P.Balasubramanian, PM.Geetu, L.Pradipkanti, DK Stapathy, R.Gopalan, Tailoring the optical phonon modes and dielectric properties of nanaocrystalline SrTiO3 via Yb doping, Materials research Express, 5, 046301. (2018)

- K.Muthamilselvan, M.Mayarani, GM Muralikrishna, M.Battabyal, Tuning the optical and thermoelectric properties of SrTiO8-xSn0.2FexO3 Materials research Express, 6, (2019) 045905

- B.Priyadarshini, M.battabyal, D.Das, AC Bose, R.Gopalan, tuning of Mg content to enhance the thermoelectric properties in binary Mg2+δSi (δ=0,0.1,0.15,0.2) materials Research Express, 6, (2019) 125519.

- B.Jayachandren, Titas Dasgupta, R.Gopalan, D.Sivaprahasam, “Elevated temperature behavior of CuPb18SbTe20/n-Ag/Cu joints for thermoelectric devices” J of Electronic Materials, 48 (2), 1276-1285 (2019)

- D.Sivaprahasam, Thermal conductivity of nanostructured Fe0.04CoSb3 Skutterudite, Materials Letter 252 (2019) 231-234.

- M.Battabyal, NS Karthisrlva, P.Rejesh, R.Gopalan, Pressure induced enhancement in the thermoelectric and mechanical properties of Ni doped skutteridites during spark plasma sintering. Materials research innovations, 2020.

- S.Harish, D.Sivaprahasam, R.Gopalan, G.Sundararajan, Design and development of new test rig for testing of automotive thermoelectric generator’ AIP Advances 9 (2019) 065004

- B.Prashant B. Prasanth a, B. Jayachandren a, Neha Hebalkar b, R. Gopalan a, S.B. Chandrasekhar b, D. Sivaprahasam a, Improved thermal stability of thermoelectric Mg2Si0.4Sn0.6, Materials Letters 276 (2020) 128204.

- B. Jayachandran, B. Prasanth, R. Gopalan, T. Dasgupta, D. Sivaprahasama, Thermally stable, low resistance Mg2Si0.4Sn0.6/Cu thermoelectric contacts using SS 304 interlayer by one step sintering., Materials Research Bulletin 136 (2021) 111147.

- V.Trivedi, M.Battabyal, S.Perumal, A.Chauhan,D.K.Satapathy, BS Murty, R.Gopalan, Effect of refractory tantalum metal filling on the microstructure and thermoelectric properties of Co4Sb12 skutterudites. ACS Omega, 2021.

Glass-like Corrosion Protection Coatings for Metals and Stainless Steels

Overview

Stainless steels (SS) look attractive due to their lustre and texture depending on finishing process and are used in innumerable applications due to their strength, ease of formability and hardenability. Stainless steels get tarnished when used at high temperature and aluminium can easily corrode in a saline environment. Organic paints and toxic hexavalent chromium-based conversion coatings are conventionally being used to render corrosion protection. However, due to the toxic nature of hexavalent chromium, sol-gel coatings are considered as eco-friendly alternatives. Sol-gel glass like coatings developed by ARCI offer excellent abrasion resistance and protection against corrosion while being eco-friendly, maintaining transparency and gloss. These coatings offer excellent tarnish resistance up to 500oC and can even be made coloured by introducing suitable pigments.

Key Features

- Suitable for application on Al alloys and SS

- Anti-fingerprint, easy-to-clean

- High scratch hardness and abrasion resistance

- High temperature tarnish protection

- Low temperature curable compositions used as replacement for chrome-free primers

- Protection against acid attack and ion leaching

Potential Applications

- Household appliances

- Medical/surgical instruments

- Automotive exhaust parts for motor cycles, cars etc.

- Architectural and interior decoration

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up and large area performance evaluated

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- An Improved Composition for Coating Metallic Surfaces and a Process for Coating such surfaces using the Composition, Indian patent application 620/DEL/2010 dtd 17-03-10.

- R. Subasri, A. Jyothirmayi and D.S. Reddy (2010): Effect of plasma surface treatment and heat treatment ambience on mechanical and corrosion protection properties of hybrid sol-gel coatings on aluminum” , Surface and Coatings Technology, 205, 806-813.

- P. Kiruthika, R. Subasri, A. Jyothirmayi, K. Sarvani, N.Y. Hebalkar (2010): Effect of Plasma Surface Treatment on Mechanical and Corrosion Protection Properties of UV-Curable Sol-Gel based GPTS-ZrO2 Coatings on Mild Steel, Surface and Coatings Technology, 204 1270-1276.

Hard Coatings on Plastics

Overview

Plastics, especially transparent plastics are being used extensively for wide ranging applications such as windshields, headlamps and ophthalmic lenses due to their lightweight, impact resistance and low temperature formability etc. But they are prone to scratch and abrasion and hence, require a protective coating. In applications such as retro reflective lenses of pavement/road markers, the coated lenses need abrasion-resistance and outdoor durability to serve for a long time. Most critical requirements of all such coatings are low temperature processing and retaining transparency even after coating deposition. Sol-gel nanocomposite hard coatings, which can be cured at low temperatures, offer excellent scratch and abrasion resistance while maintaining transparency and hence, can successfully be used in wide ranging applications.

Key Features

- High scratch hardness and abrasion resistance

- Long life

- Good adhesion

- Coloured coatings possible

- Can be coated on Polycarbonate, PMMA etc

- Can be made easy-to-clean with low surface free energy

Potential Applications

- Road transport: Road and pavement markers

- Helmet visors

- Automotive headlamps/windshields

- Coloured head lamps for improved aesthetic appeal and style

- Ophthalmoscopic lenses

- Bi-aspheric lenses used in indirect ophthalmoscopy

- Aircraft canopy

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

- Scale-up and large area performance to be evaluated

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- Improved Scratch And Abrasion Resistant Compositions for Coating Plastic Surfaces, A Process for their Preparation and a Process for Coating using the Compositions, Indian Patent Application number: 2427/DEL/2010 dtd 12-10-10

- S.T. Gururaj, R. Subasri, K.R.C. Soma Raju and G. Padmanabham, “Effect of Plasma pretreatment on adhesion and mechanical properties of UV-curable coatings on Plastics” Applied Surface Science 257 (2011) 4360–4364.

- K.R.C. Soma Raju, L. Sowntharya, S. Lavanya and R. Subasri (2012) “Effect of plasma pretreatment on adhesion and mechanical properties of sol-gel nanocomposite coatings on polycarbonate”, Composite Interfaces, 19:3-4, 259-270.

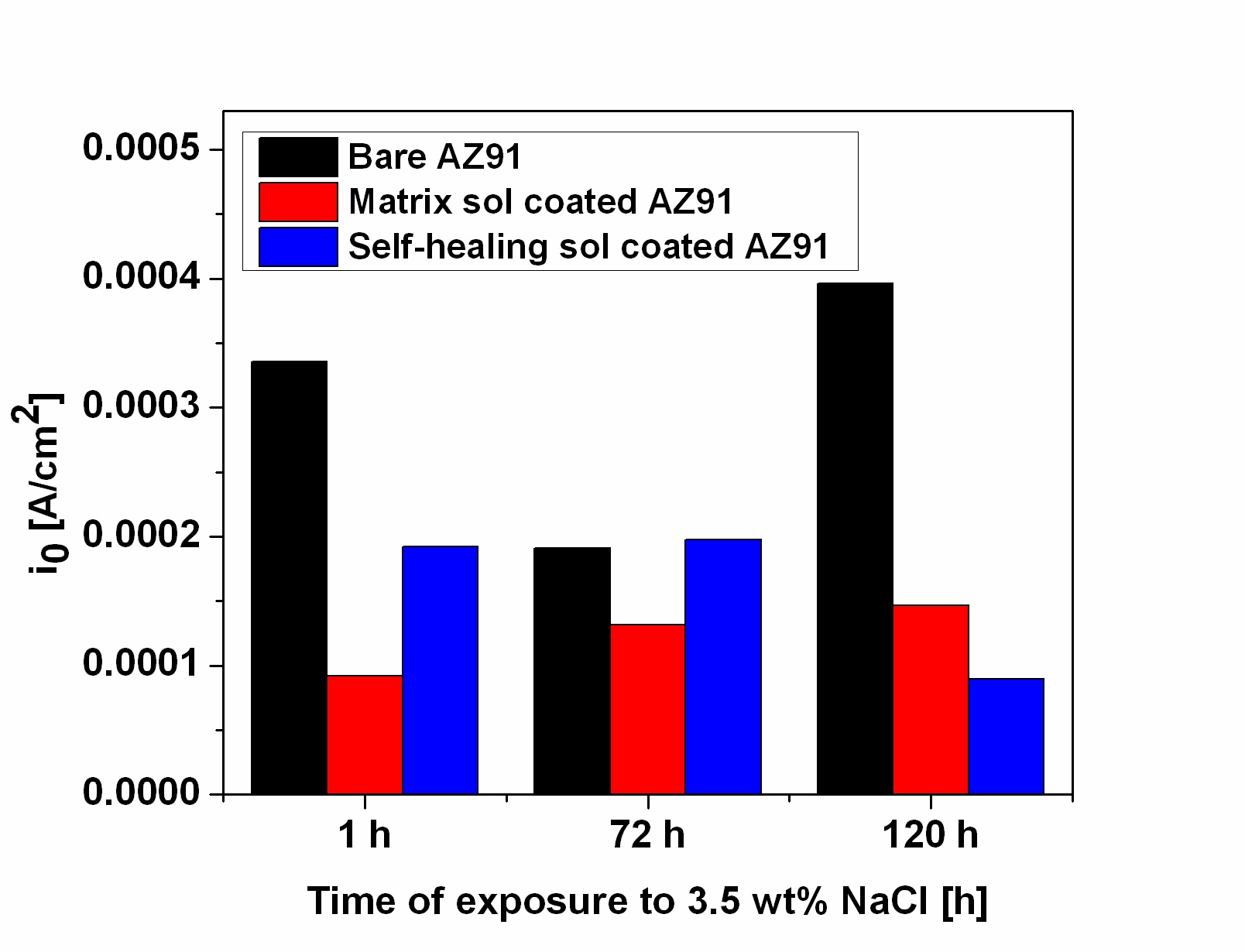

Self-Healing, Corrosion Protection Coatings on Al and Mg Alloys

Overview

Key Features

- Non-toxic and eco-friendly

- Amenable to coat large areas with easy automation

- Good adhesion to the substrate materials

- Can be applied as bond coat to promote adhesion of primers

- Can be made as Decorative coatings also

- Low temperature (≤130oC) curable

Potential Applications

- Aircraft bodies

- Automotive components

- Any Al/Mg alloy component

- Can be used as an additive in paints/primers to enhance corrosion protection

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated on coupons at laboratory scale

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents

- An improved coating composition to provide prolonged corrosion protection to anodizable metal surfaces and process of preparing the same Indian Patent Application number 3082/DEL/2015 dtd 28-09-15.

- An improved composition for coating anodizing metal surfaces and a process of coating the same. Indian Patent Application number: 1310/DEL/2013 dtd 03-05-13.

- N. Kumar, A. Jyothirmayi, K. R. C. Soma Raju, V. Uma and R. Subasri (2013): One Step Anodization/Sol-Gel deposition of Ce3+-doped silica-zirconia Self- Healing Coating on Aluminum, ISRN Corrosion, article id 424805

-1.jpg)

-2.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)