Centre for Materials Characterization and Testing (CMCT)

Corrosion Testing Facility

A. Cycling Corrosion Cabinet

Model &Make

CCX 2000, Atlas Material Testing Solutions, USA

Specifications

Details

To better understand the potential for adverse effects of outdoor exposure, materials are regularly tested to various environmental conditions. The cyclic corrosion cabinet is now accepted as superior at duplicating actual environments. It improves repeatability, reduces time spent in handling samples and also operator error by creating different environments in one cabinet. Standard exposure cycles like salt or chemical fog, water fog, salt spray, dry-off cycle, high temperatures i.e. up to 70oC can be increased for required time from hours to number of days which are closer to environmental changes.

Salient features-Materials of different sizes and shapes can be tested under various environmental conditions by using various standard methods like ASTM B117, ASTM G85 A5, CCT I, CCT IV, SAE J2334 and GM9540B.

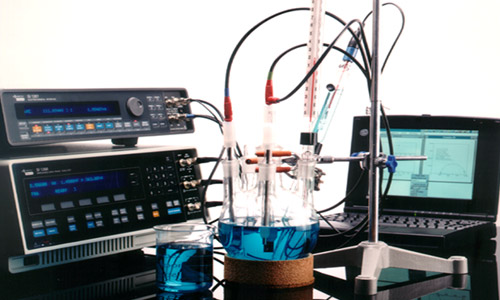

B. Electrochemical Corrosion Testing Equipment

The electrochemical testing system consists of two units. Electrochemical interface and impedance/gain-phase analyzer along with softwares corroware and Z plot

a) Electrochemical Interface

Model & Make

SI1287-Solartron, U.K

Details

The corrosion is an electrochemical process and electrochemical potential is the driving force for reactions. The principle employed in the electrochemical interface is based on the application of a controlled voltage to a sample (working electrode) and measurement of the change in current, or vice versa. The corrosion rates of the specimens can be determined using CorrWare programme. Most of the corrosion types uniform, localized, galvanic, dealloying; stress corrosion and hydrogen-induced failure can be analyzed by this technique. Conventional electrochemical experiments like static, dynamic polarization, potentiostatic, potentiodynamic experiments etc. can be done. This system is extensively used to study the corrosion properties of coated substrates. Based on the results, further improvement of coatings has been done. Different types of coatings like DLC on Al alloys, MAO coatings on Al, Coating on steels and Al alloys by Sol-Gel technique, materials like Mg-Zn, steels, alloys have been analyzed. The system can also be used to study batteries, fuel cells, inhibitors, electroplating and catalytic properties etc.

b) Impedance/Gain-Phase Analyzer for EIS

Model & Make

SI1260-Solartron, U.K

Specifications

Frequency range 10 µHz to 32 MHz with 10 µHz resolution.

Details

Electrochemical Impedance Spectroscopy is a powerful technique, which can provide lot of information on corrosion reactions, mass and charge transport, the characteristics of material and coating in different electrolytes. An electrode interface undergoing an electrochemical reaction is typically analogous to an electronic circuit consisting of a specific combination of resistors and capacitors. This is used to characterize the electrochemical system in terms of its equivalent circuit. The system is widely used in characterization of materials, batteries, and coatings and to illustrate their corrosion mechanism. It is also used for investigating mechanisms in electrodeposition, electrodissolution, passivity and corrosion studies.

Centre

Centre for Material Characterization and Testing

High Flux X-ray diffraction (XRD)

Model & Make

SmartLab 2018, Rigaku, Japan

Details

High Flux X-ray diffraction (XRD) unit is equipped with 9kW rotating Cu anode which provides nearly one order higher flux on the sample than the sealed tube X-ray source. This XRD machine can be used to carry out angular dispersive scans with 2 from 5 to 160 deg. and an angular resolution of 0.01 degrees. Specially designed sample holders are available for mounting of solid samples and powder samples. With aid of auto sampler robot, a maximum of 48 powder and 24 bulk samples can be measured with operator intervention.

Centre

Centre for Material Characterization and Testing

Instrumented Indentation Testing Facility

Make :

Micro Materials Ltd., Wrexham LL13 7YL, UK

Model:

Nanotest Vantage (Alpha) with NTX4 Contoller

Specifications:

Low load Head (up to 500mN); High Load Head ( Max.20N)

Testing modules:

- Hardness and Modulus

- Scratch

- Nano-impact

- Dynamic Hardness

- Low cyclic and High Cyclic Fatigue

- Imaging

- Dynamic Mechanical Compliance Testing

Centre:

Centre for Materials Characterization and Testing (CMCT)

Macrohardness Tester

Model & Make

Leco, LV700AT

Specifications

Computer-controlled unit Load range from 0.3 to 30 kgf Accommodate both Vickers and Knoop indenters

Details

With the aid of computer control, arrays of indents can be made on the sample and the hardness can be measured as a function of distance from a reference point. This unit is especially suitable to induce cracks on the sample surface so that the fracture toughness can be measured.

Centre

Centre for Material Characterization and Testing

Microhardness Tester

Model and Make

UHL VMHT

Specifications

- Computer-controlled unit

- Load range from 0.3 to 30 kgf

- Accommodate both Vickers and Knoop indenters

Details

With the aid of computer control, arrays of indents can be made on the sample and the hardness can be measured as a function of distance from a reference point. This unit is especially suitable to induce cracks on the sample surface so that the fracture toughness can be measured.

Centre

Centre for Material Characterization and Testing

Multi-functional high intensity 2D X-ray Diffraction system

Model and Make:

RAPID-II-D/MAX X-ray Diffraction System (RIGAKU Corp., Japan)

Specifications:

Rigaku-MICROMAX 007 HF rotating anode (Cu and Cr target); 2D-curved image plate detector (size: 470 x 256mm); collimators: 10, 30, 50, 100, 300 and 800 mm diameter; 2theta range: -47 to +163 degree

Details:

This is the most versatile laboratory scale x-ray diffraction system. It is equipped with high intensity microfocus rotating anode x-ray source-Rigaku MicroMax 007HF, which has brightness close to a second generation synchrotron with x-ray flux of 10^14 x-ray photon/mm^2/s at the focal point. The system also has a highly sensitive and large image plate based 2-dimensional (2D) detector, which ensures a full scan from -47 to +163 degree for 2theta in a single exposure of very small duration. It has both Cu and Cr target option with provision to bring the beam spot size down to 10 micron. The system can be operated in reflection, transmission and glancing incidence configuration. It can perform wide range of studies like phase analysis, texture, residual stress, trace phase detection (for phase fraction of 0.1-1% or less) in micro/macro-area apart from thin film analysis in the glancing incidence mode. In addition, it has a provision to perform fully automated area mapping using auto stage.

Non-Contact Optical Profilometer

Model & Make

NV6200, Zygo

Details

The system is used for estimating surface roughness and other surface parameters, as also to create 3D profiles of surfaces. It uses white light interferometry to map specimen surfaces. A beam splitter is used to split the incoming beam into two. One part goes to a reference mirror that is optically smooth while the other part scans the sample surface. The interference pattern between the two beams (that is, the one coming from the reference mirror and the other from the sample) is used to recreate the surface profile. The resolution of the unit is 0.1 nm and hence optically smooth surfaces can be studied. An advantage of this system over an atomic force microscope is that there is no mechanical contact with any part of the sample and hence even smooth and soft surfaces can be profiled. Another advantage is that the optics stay much above the sample and hence even deeper areas of the sample surface can be imaged as far as the light beam is able to fall on the area of interest.

Centre

Centre for Material Characterization and Testing

Optical Microscope

Model & Make

GX51, Olympus

Details

This microscope, is useful for visual examination of samples to magnifications of 1000x. The microscope has an image analyser attached to it that is used for quantification of the images. Measurements of grain size, porosity etc. are possible with the software. The microscope also has a DIC filter that is useful for the observation of sample topography.

Centre

Centre for Material Characterization and Testing

Scanning Electron Microscope with Field Emission Gun (FE-SEM)

Model & Make

Gemini 500 (M/s Carl Zeiss)

Details

This instrument is used for studying sample surfaces at high magnifications (> 200000x) due to the presence of a hot Schottky field emission (FE) gun. Potential (called the extraction voltage) is applied to draw out the electrons. Due to this combination of high temperature and extraction voltage, the brilliance of the source beam, as also its stability, is high. This system is attached with an EDS unit and an electron back scatter diffraction (EBSD) unit.

Attachment to the FE-SEM

A. Energy Dispersive Spectroscope

Details

One of the interactions that occur when an incident electron beam falls on a sample is the production of x-rays from the sample. The x-ray frequency is characteristic of the element in the sample that produces it. Thus, several elements can be analysed simultaneously. The detector analyses the energies of the generated x-rays, leading to speedy detection of the elements.

Centre:

Centre for Material Characterization and Testing

B. Electron Back Scatter Diffraction unit

Details

In the EBSD unit, the sample is kept inclined at an angle of 70 to the incident beam and the emergent backscattered electrons undergo diffraction. The diffracted beams are collected on a phosphor screen where they form bands that are indexed based on known crystallographic inputs. The electron beam moves on the sample surface in a regular manner based on a step size determined by the user. Electron diffraction occurs at each point and the entire area of interest on the sample surface is mapped. EBSD is a technique where the input is crystallographic information and the output is microstructural information. The orientation of individual grains can be measured using EBSD, as also the grain shape, size and boundary statistics. EBSD is also a powerful tool for the determination of crystallographic texture. A special feature of the unit at ARCI is that the EDS and EBSD units work in synchronisation and hence elemental and microstructual information can be collected from each point from the area of interest. A recent area of application is phase analysis using the EDS/EBSD combination. Since spatial information from the different grains is preserved in EBSD, the location of small amounts of secondary phases (at triple points or within grains) can be determined accurately.

Centre

Centre for Material Characterization and Testing

Small Angle X-ray Scattering (SAXS)

Model & Make

Xeuss 1.0, & Xenocs, France

Specifications

Dual energy Mo and Cr micro source, Camera length : 2400 mm, q range: 0.024 to 14 nm-1

Details

A laboratory small-angle X-ray scattering (SAXS) system with a dual energy (Mo and Cr) source has been designed with the aim of studying the heterogeneity in high-Z metallic structural materials such as steels (Fe alloy) and other materials. With the combination of Mo and Cr energies, various camera lengths (maximum of 2400 mm), and an area detector, three decades of q range has been achieved, from 0.024 to 14 nm-1. In real space, the probing periodic distance is a maximum of 261 nm. In addition to having Mo and Cr sources, a flexible sample mounting stage permits measurements on a wide range of materials in transmission geometry. More details about instrument can be found at "A multi-functional dual-energy laboratory Mo-Cr-SAXS system" J. Appl. Cryst. (2015). 48, 2040-2043

https://doi.org/10.1107/S1600576715018804

http://scripts.iucr.org/cgi-bin/paper?S1600576715018804

Centre

Centre for Materials Characterization and Testing (CMCT)

Incharge

Dr. K. Suresh

TEM Sample Preparation Equipment

- Disc Punch and Ultrasonic Disc Cutter

- Dimpler Grinder

- Ion Milling and Electrochemical Polishing

- Electropolishing Unit

Transmission Electron Microscope (TEM)

Make and Model

TecnaiG2, FEI

Specifications and features

- excitation voltage : 200kV

- electron source : LaB6

- S-twin objective lens

- Magnification range: 25X to 1000K X

- 5 axis compu-stage, α: ± 40, β: ± 30 deg

- Resolution, Point: 0.24 nm, Line : 0.14 nm

- EDAX EDS spectrometer for chemical analysis

- Gatan Image Filter for elemental analysis and mapping

Details

This instrument is used for studying samples at very high magnifications (> 500000X) in transmission. Samples of 3mm diameter are prepared such that the thickness at the centre is 200 nm or less so that electron transparency can be achieved. The incident electron beam can be accelerated to 200 kV and on passing through the sample, several interactions take place. The transmitted beam is then used for imaging and also electron diffraction studies. The system is equipped with an LaB6 filament providing a high beam current and long filament life. The unit has EDS and Electron Energy Loss Spectroscopy attachments, both of which are techniques for elemental analysis. In the later technique, the energy lost by the incident beam on passing through the sample is measured and thus elemental information can be obtained.

Centre

Centre for Material Characterization and Testing

Universal Testing Machine

A. Specifications

Load applied on test piece: upto 150 kN

Details

This unit is used to study the mechanical properties of materials under tension and compression. The sample to be tested is gripped between the lower fixture of the unit and the upper crosshead and the desired load is applied. The computer interface measures the crosshead movement and the extension/compression of the sample. The unit is equipped with a video extensometer so that the change in dimension of the sample can be measured without any sensors coming in contact with the sample. Extra ports are available for additional devices such as an ultrasonic detector to study grain boundary migration.

B. Model & Make: KUT-40

Specifications

- Machine load capacity: 0-40 tonne

- Minimum graduations: 10-100Kgf with margin of error ±1%

Details

Universal Testing machine is for conducting tests like tension, compression, bending, etc., on metals and other materials. The machine is electrically driven and specimen loading is achieved hydraulically. The machine is equipped with pendulum dynamometer recording device for registering load-deformation diagram.

X Ray Diffraction

Model & Make

D8 Advance, Bruker

Details

X-ray diffraction (XRD) is one of the basic tools for material characterisation and is used to obtain structural information on an atomic scale from both crystalline and non-crystalline (amorphous) materials. XRD is a non-destructive technique and can be successfully applied to determine crystal structures of various types of materials such as metals, alloys, ceramics and inorganic compounds, in both the bulk and thin-film/coating forms. XRD also can be applied to obtain structural information such as crystallite size, lattice strain and crystal orientation. The X-ray diffractometer is a versatile instrument for phase and structural analysis of metals, powders and thin-films. The unit at ARCI is equipped with a Cu source and a high speed 1D Lynx Eye detector mounted on a vertical goniometer. This XRD machine can be used to carry out angular dispersive scans with 2 from 5 to 160 deg. and an angular resolution of 0.002 deg. Specially designed sample holders are available for mounting of solid samples with different thicknesses and powder samples on a horizontal spinning (omega) sample stage. For regular powders and other bulk specimens, XRD profiles acquired in (symmetric) geometry, whereas for the thin films and coatings, these profiles are obtained using what is called as grazing incidence XRD (GI-XRD).

Centre

Centre for Material Characterization and Testing