Centre for Sol-Gel Coatings (CSOL)

Anti-microbial, Easy to clean Coatings on Glass, Metals, Plastics and Fibres

Overview

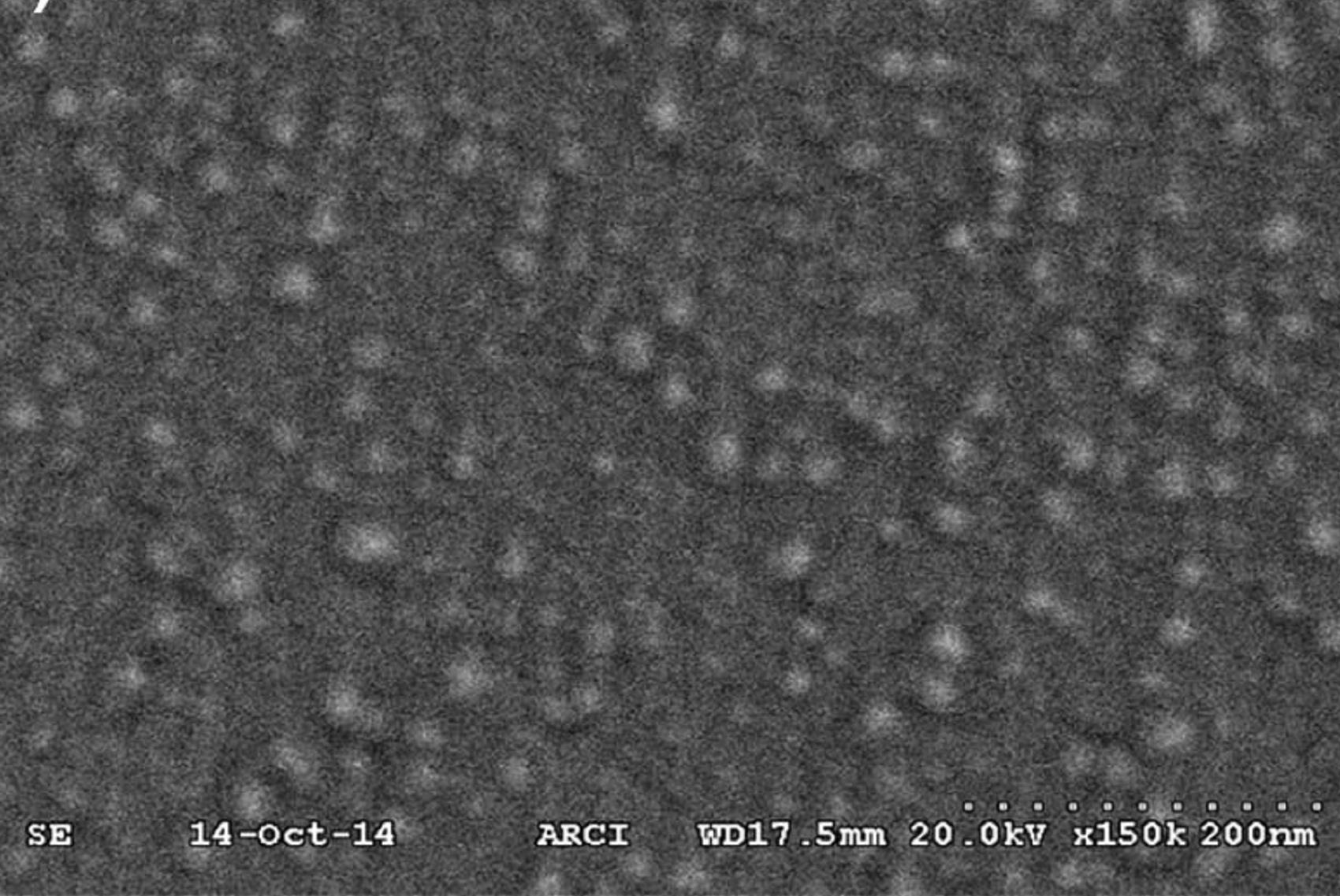

Contamination of walls, floors and surfaces of many articles that we use in day-to-day life is the main reason for disease to spread rapidly. Hence, ensuring that these surfaces are free of microbial contamination, especially in hospitals, is an important factor in maintaining the general health of people. Silver in the form of metallic silver or silver salts is known to be toxic to micro-organism, particularly bacteria while being relatively harmless to a man. When nano scaled silver is introduced to a hybrid sol-gel matrix, it results in an antimicrobial coating due to the silver nanoparticles and scratch resistant due to the inorganic network of sol-gel coatings providing high degree of abrasion resistance too. This helps in retarding the growth of microbes and thus minimizes the use of autoclaving process or cleaning using harsh chemicals. Other functionalities such as easy-to-clean property can also be incorporated into the coatings.

Key Features

- Incorporation of anti-microbial nanoparticles, controlled release mechanism

- Easy-to-clean coatings have surface properties comparable to perfluorinated polymers (hydrophobic surface)

- Non-toxic

- Easy to scale up for large area coatings

Potential Applications

- Medicine bottles/containers

- Hospital wall panels, hospital furniture

- Hearing aids

- Food packaging

- Textile walls and textile roofs, sun shades, blinds

- As top coats on wall paints

- Anti-fouling coatings on marine floating objects

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- R. Subasri, H. Hima, Investigations on the use of nanoclay for generation of superhydrophobic coatings, Surface & Coatings Technology, 264 (2015) 121– 126.

- K. Jeevajothi, R. Subasri, K.R.C. Soma Raju (2013): Transparent, Non-fluorinated, Hydrophobic Silica Coatings with Improved Mechanical Properties, Ceramics International, 39, 2111-2116.

- R. Dineshram, R. Subasri, K.R.C. Somaraju, K. Jayaraj, L. Vedaprakash, Krupa Ratnam, S.V. Joshi, R. Venkatesan, Biofouling studies on nanoparticle-based metal oxide coatings on glass coupons exposed to marine environment, Colloids and Surfaces B: Biointerfaces 74 (2009) 75–83

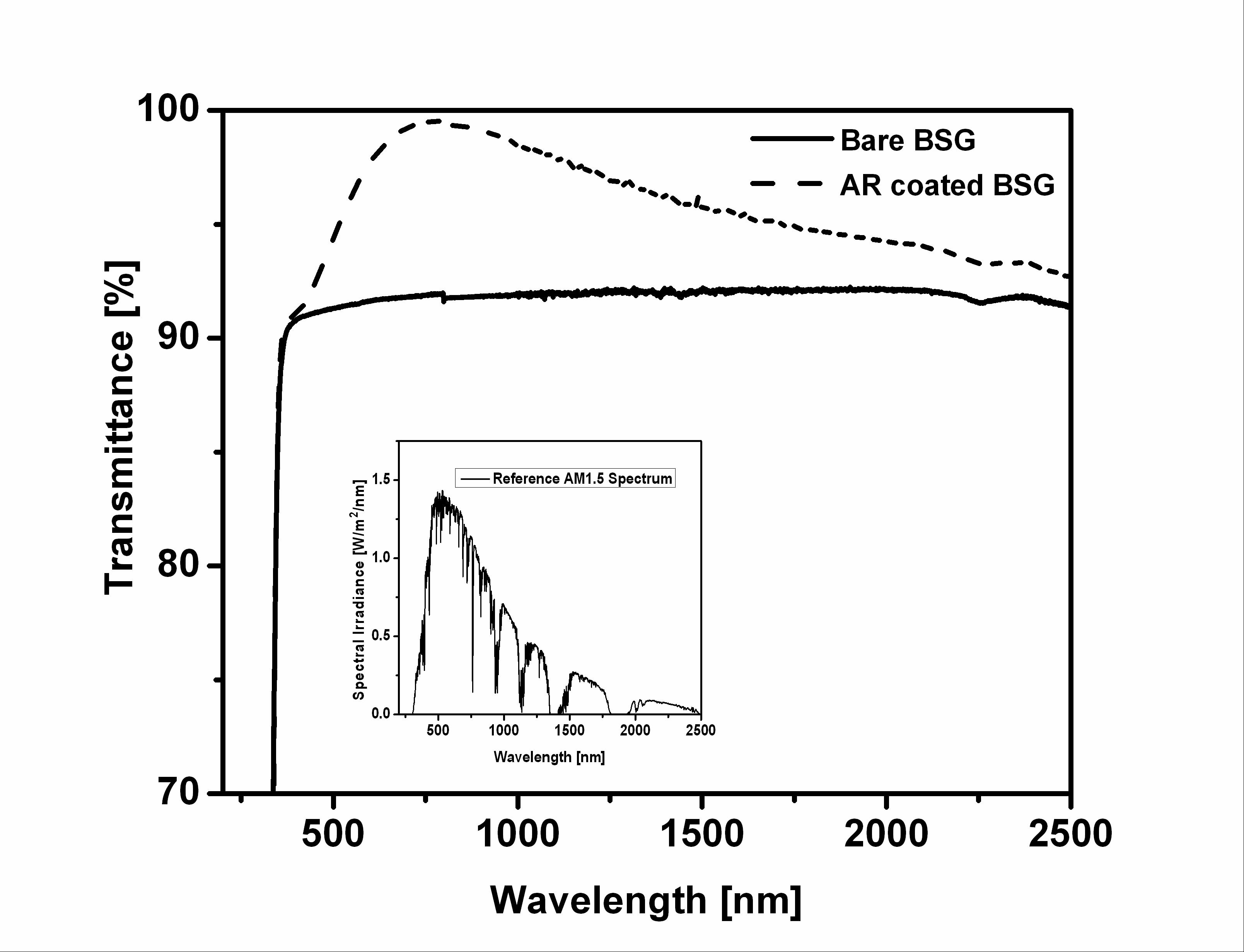

Scratch-Resistant, Single Layer Antireflective Coatings on Glass and Plastics

Overview

Key Features

- Visible light transmission ~ 97%

- Haze change after 1000 cycles of crockmeter testing using fabric: <2%

- Can be applied on Polycarbonate, PMMA and window glass

- Eco-friendly

- Low temperature ultraviolet (UV)/near-infrared (NIR) curability

- Amenability for deposition on large areas with automation

Potential Applications

- Smart windows

- Automobile windows

- Transparent glass for photovoltaic modules

- Protective glass cover for solar thermal heat collection elements

- Ophthalmic lenses

- Helmet visors

- Display glass for showcase

- Aircraft canopy

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale on coupons

- Scale-up and prototype validation to be carried out

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An improved composition for antireflective coating with improved mechanical properties and a process of coating the same, Indian patent application number 2330/DEL/ 2013 dtd 05-08-13.

- S. Pavithra and R. Subasri, Sol-gel derived single layer zeolite-MgF2 composite antireflective coatings with improved mechanical properties on polycarbonate, Journal of Coating Science and Technology 1 (2014) 8-16.

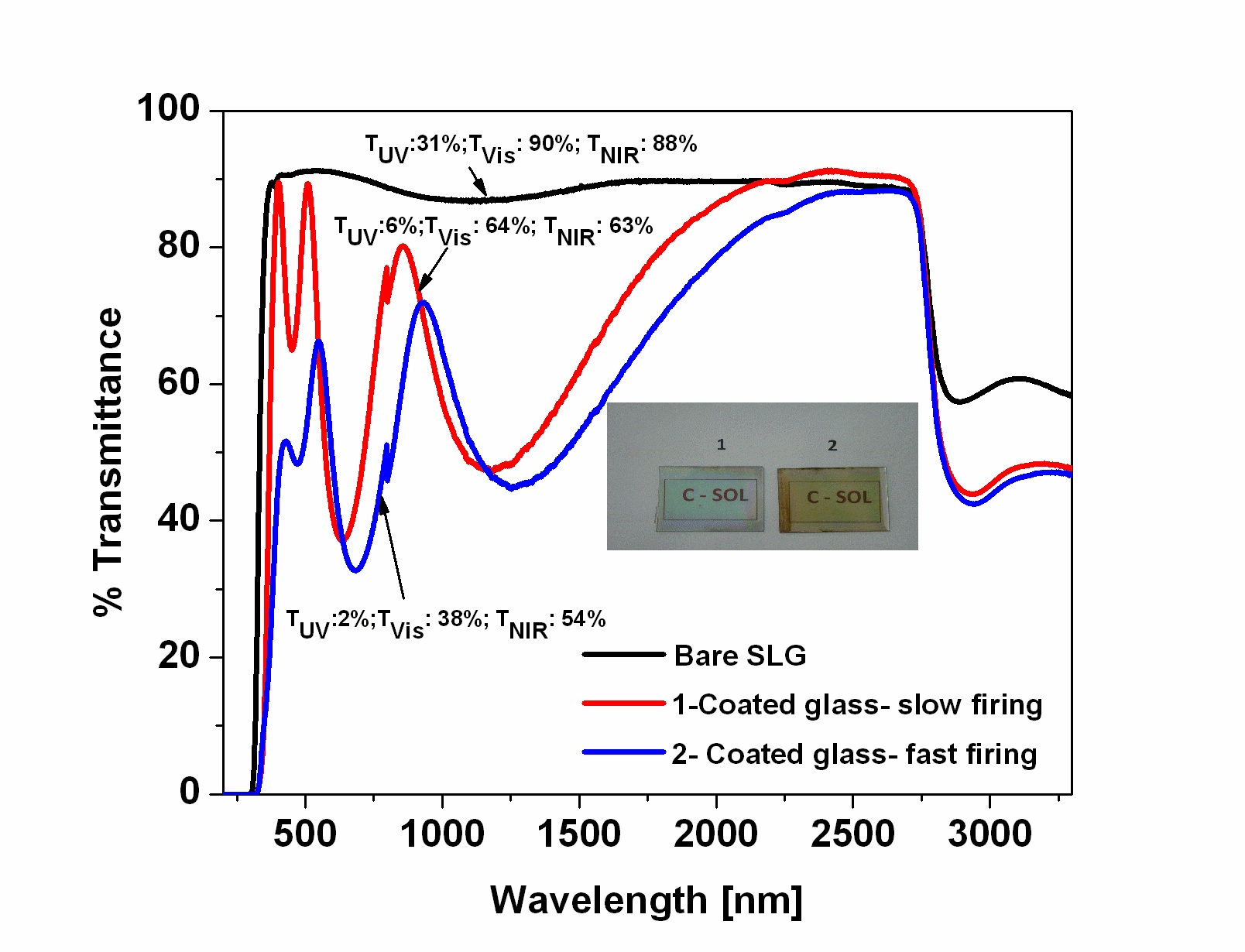

Solar Control Coatings on Glass

Overview

Key Features

- Visible light transmission -35-65% vis-a -vis 90% for bare glass

- UV transmittance - 2% vis-a -vis 30% for bare glass

- NIR transmittance - 55% vis-a -vis 85% for bare glass

Potential Applications

- Architectural window glass

- Automobile side window glass/windshields

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Proof of concept successfully completed and scale-up can be demonstrated based on the market demand

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An improved process to make coating compositions for transparent, UV blocking coatings on glass and a process of coating the same, Indian patent application number 1152/DEL/2014 dtd 29-04-14

- S. Manasa, R. Subasri, Effect of heat treatment on the optical properties of sol-gel derived, fully dielectric solar control coatings on glass, J. Coatings Technology and Research 13 (2016) 623-628.

Glass-like Corrosion Protection Coatings for Metals and Stainless Steels

Overview

Stainless steels (SS) look attractive due to their lustre and texture depending on finishing process and are used in innumerable applications due to their strength, ease of formability and hardenability. Stainless steels get tarnished when used at high temperature and aluminium can easily corrode in a saline environment. Organic paints and toxic hexavalent chromium-based conversion coatings are conventionally being used to render corrosion protection. However, due to the toxic nature of hexavalent chromium, sol-gel coatings are considered as eco-friendly alternatives. Sol-gel glass like coatings developed by ARCI offer excellent abrasion resistance and protection against corrosion while being eco-friendly, maintaining transparency and gloss. These coatings offer excellent tarnish resistance up to 500oC and can even be made coloured by introducing suitable pigments.

Key Features

- Suitable for application on Al alloys and SS

- Anti-fingerprint, easy-to-clean

- High scratch hardness and abrasion resistance

- High temperature tarnish protection

- Low temperature curable compositions used as replacement for chrome-free primers

- Protection against acid attack and ion leaching

Potential Applications

- Household appliances

- Medical/surgical instruments

- Automotive exhaust parts for motor cycles, cars etc.

- Architectural and interior decoration

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up and large area performance evaluated

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An Improved Composition for Coating Metallic Surfaces and a Process for Coating such surfaces using the Composition, Indian patent application 620/DEL/2010 dtd 17-03-10.

- R. Subasri, A. Jyothirmayi and D.S. Reddy (2010): Effect of plasma surface treatment and heat treatment ambience on mechanical and corrosion protection properties of hybrid sol-gel coatings on aluminum” , Surface and Coatings Technology, 205, 806-813.

- P. Kiruthika, R. Subasri, A. Jyothirmayi, K. Sarvani, N.Y. Hebalkar (2010): Effect of Plasma Surface Treatment on Mechanical and Corrosion Protection Properties of UV-Curable Sol-Gel based GPTS-ZrO2 Coatings on Mild Steel, Surface and Coatings Technology, 204 1270-1276.

Hard Coatings on Plastics

Overview

Plastics, especially transparent plastics are being used extensively for wide ranging applications such as windshields, headlamps and ophthalmic lenses due to their lightweight, impact resistance and low temperature formability etc. But they are prone to scratch and abrasion and hence, require a protective coating. In applications such as retro reflective lenses of pavement/road markers, the coated lenses need abrasion-resistance and outdoor durability to serve for a long time. Most critical requirements of all such coatings are low temperature processing and retaining transparency even after coating deposition. Sol-gel nanocomposite hard coatings, which can be cured at low temperatures, offer excellent scratch and abrasion resistance while maintaining transparency and hence, can successfully be used in wide ranging applications.

Key Features

- High scratch hardness and abrasion resistance

- Long life

- Good adhesion

- Coloured coatings possible

- Can be coated on Polycarbonate, PMMA etc

- Can be made easy-to-clean with low surface free energy

Potential Applications

- Road transport: Road and pavement markers

- Helmet visors

- Automotive headlamps/windshields

- Coloured head lamps for improved aesthetic appeal and style

- Ophthalmoscopic lenses

- Bi-aspheric lenses used in indirect ophthalmoscopy

- Aircraft canopy

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

- Scale-up and large area performance to be evaluated

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- Improved Scratch And Abrasion Resistant Compositions for Coating Plastic Surfaces, A Process for their Preparation and a Process for Coating using the Compositions, Indian Patent Application number: 2427/DEL/2010 dtd 12-10-10

- S.T. Gururaj, R. Subasri, K.R.C. Soma Raju and G. Padmanabham, “Effect of Plasma pretreatment on adhesion and mechanical properties of UV-curable coatings on Plastics” Applied Surface Science 257 (2011) 4360–4364.

- K.R.C. Soma Raju, L. Sowntharya, S. Lavanya and R. Subasri (2012) “Effect of plasma pretreatment on adhesion and mechanical properties of sol-gel nanocomposite coatings on polycarbonate”, Composite Interfaces, 19:3-4, 259-270.

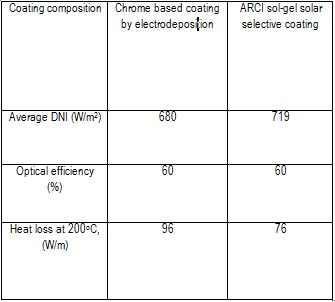

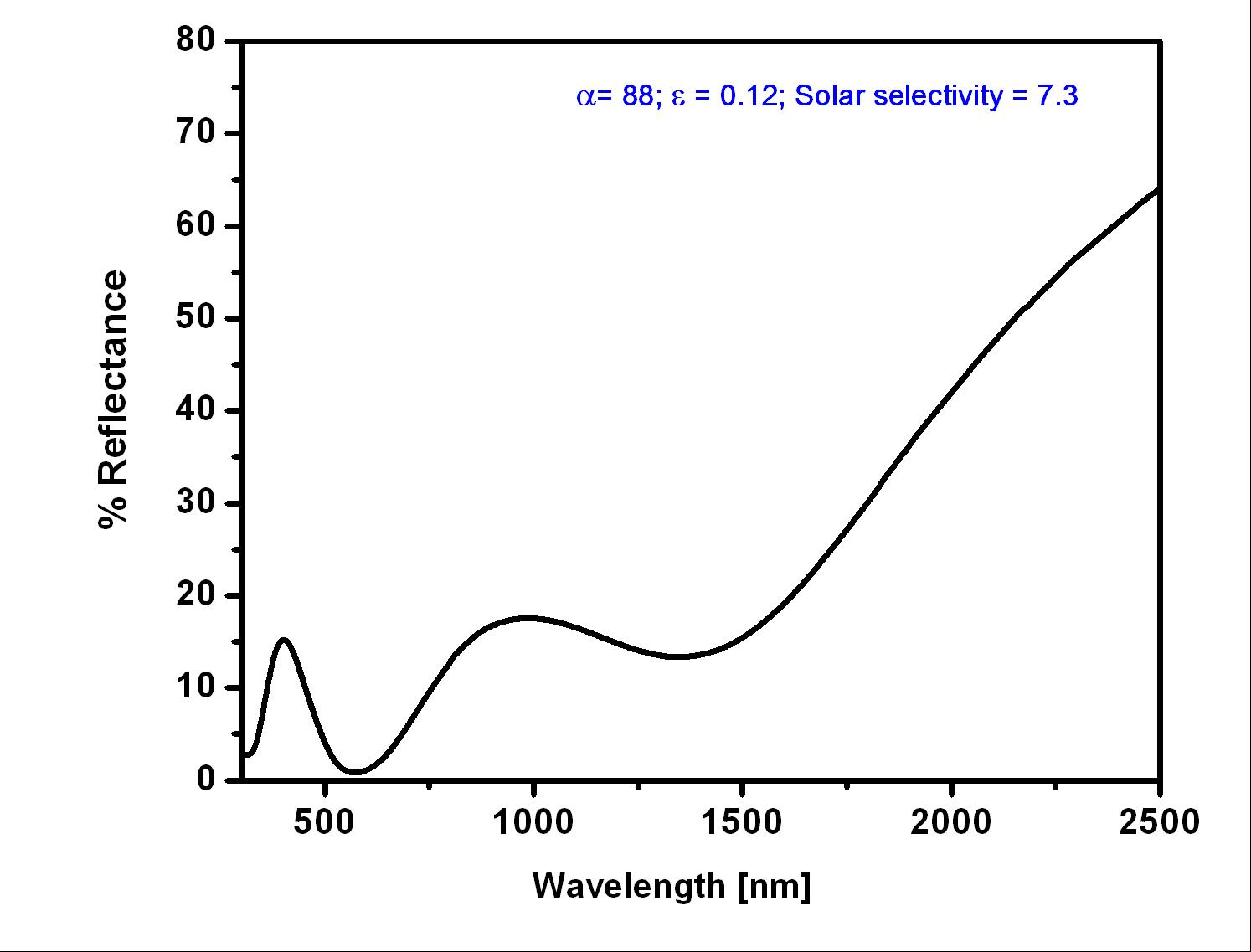

Solar Selective Coatings for Stainless Steel and Aluminium Substrates

Overview

Key Features

- 94 ± 1 % absorbance in 300-1500 nm range

- 14 ± 1 % Thermal IR emittance

- Withstood 20 cycles of thermal cycling at 350oC

- Withstood 80 h of salt spray test as per ASTM B117

- Non-toxic and environmental friendly

Potential Applications

- Solar selective coatings on absorber tubes of Concentrated Solar Power plant (Non-evacuated up to 250 deg C and evacuated up to 400 deg C)

- Solar selective coatings on metal tubes for water heating applications (up to 100 deg C)

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

- Scale-up and prototype testing completed

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An improved composition for solar selective coatings on metallic surfaces and a process for its preparation and a process for coating using the compositions, Indian patent application number 3324/DEL/2011 dtd 22-11-11.

- R. Subasri, K.R.C. Soma Raju, D.S. Reddy, Neha Y. Hebalkar, G. Padmanabham, Sol-gel Derived Solar Selective Coatings on SS 321 Substrates for Solar Thermal Applications, Thin Solid Films 598 (2015) 46-53.

- Priya Anish Mathews, K.R.C. Soma Raju, Sanjay Bhardwaj and R. Subasri (2013): Sol-Gel Functional Coatings for Solar Thermal Applications: A Review of Recent Patent Literature, Recent Patents on Materials Science 6, 195-213.

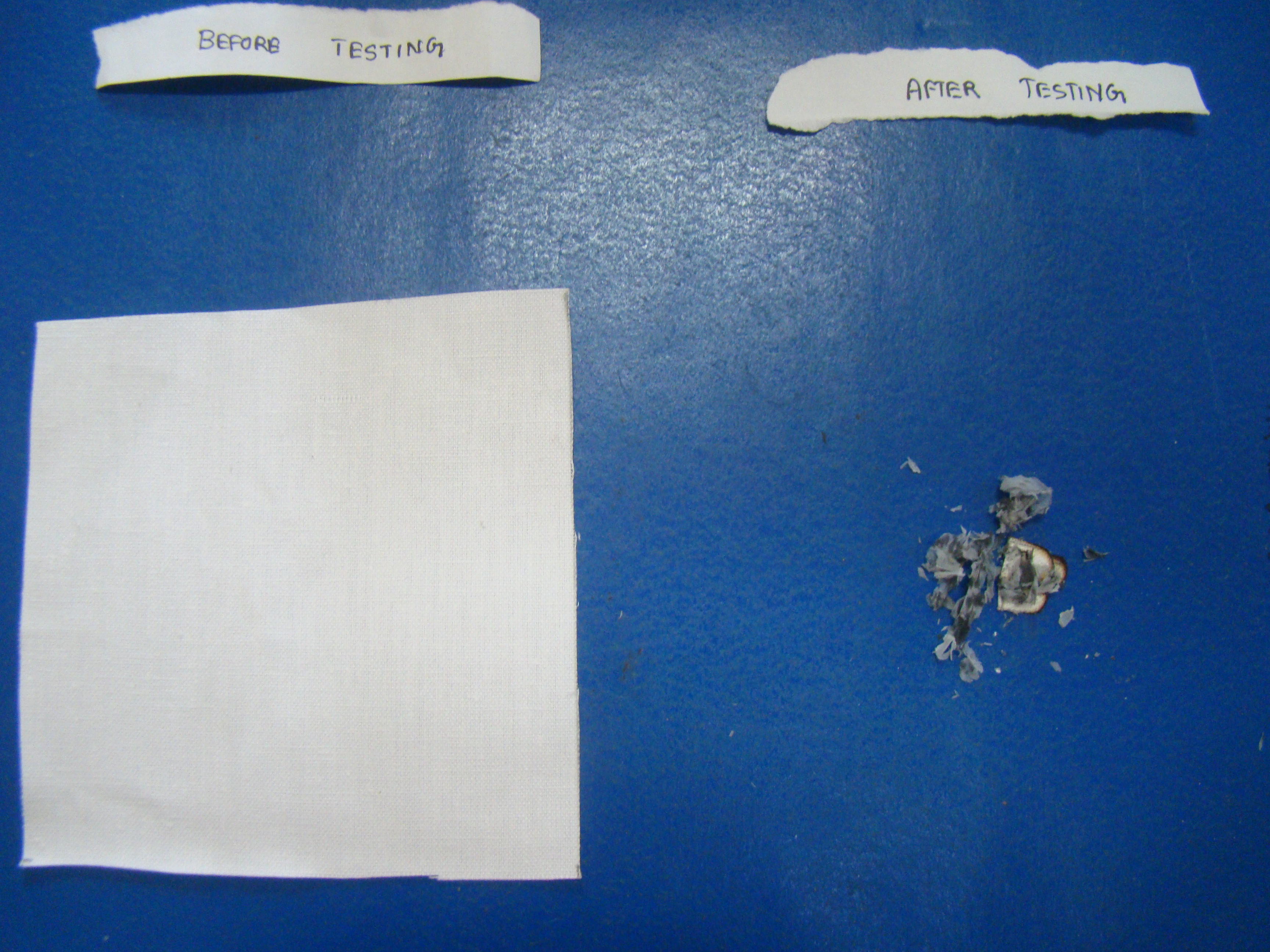

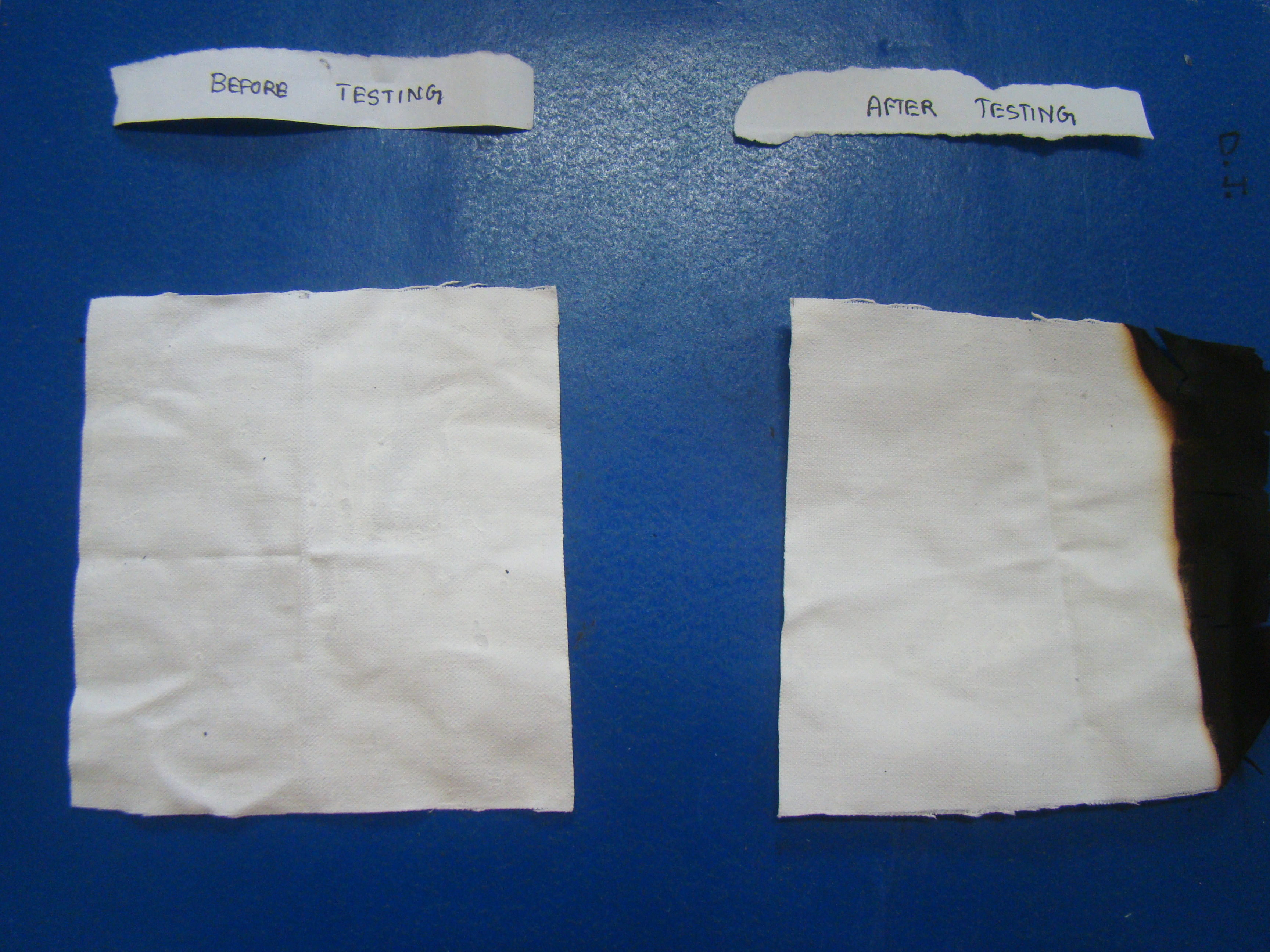

Flame Retardant Coatings on Fabrics

Overview

There has been a recent requirement of halogen-free flame retardant (FR) finish for textiles due to the toxic nature of halogenated flame retardant finish on fabrics. In addition, organic solvent based formulations have also come under scrutiny in recent years. Hence, water-based and halogen-free sol-gel composition is a basic requisite for synthesis of safe and eco-friendly flame retardant formulations for fabrics. The halogen-free, water-based sol-gel coating formulation developed by ARCI when deposited on fabrics was found to increase the limiting oxygen index, provide substantial flame retardant property after ignition and self-extinguishment of the flame even if ignited. The process uses nanoscaled metal oxide powders in conjunction with a sol-gel matrix, that can provide flame retardant property along with good adhesion to the fabrics.

Key Features

- Limiting oxygen index: 37.5 % for FR treated cotton vis-à-vis < 21% for untreated cotton

- FR treated fabric does not ignite or even if ignited, self-extinguishes after 2 sec

- Can be applied on cotton, nylon, polyester

- Simple methods like dipping or padding can be used for FR treatment

- Coatings can be cured very rapidly using Near Infrared (NIR) radiation

Potential Applications

- Curtains in Air Conditioned Compartments of Railway Coaches

- Curtains in Air Conditioned Buses

- Fire fighting Garments

- Laboratory Aprons

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up and prototype validation to be carried out

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An Improved Coating Composition to Provide Flame Retardant Property to Fabrics and Process of Preparing the Same - to be filed shortly

Abrasion Resistant, Hydrophobic Coatings on Carbon-Epoxy Composites (CEC)

Overview

Carbon epoxy composites (CEC) have excellent advantages such as lightweight, high strength and weathering resistance when compared to aluminum alloys and high-grade steels. Moreover, body parts made of CEC when used for aerospace applications can be tailor-made with limited number of joints. But CEC are poor in abrasion and erosion resistance and degrade when contacted with hydraulic fluids such as water or any oil. Sol-gel formulations developed by ARCI when deposited on CEC were found to substantially improve scratch/abrasion resistance. Transparent or coloured abrasion resistant, hydrophobic coatings on polyurethane painted carbon-epoxy composite coupons could be generated using UV polymerizable silanes and their performance was found to be promising for aerospace applications. The developed coating technology was found to be amenable for scale-up and automation.

Key Features

- Eco-friendly

- Durability of hydrophobicity and abrasion resistance

- Amenable to coat large areas with easy automation

- Good adhesion to the substrate materials

- Can be applied as bond coat to promote adhesion with paints

- Can be made as coloured coatings

Potential Applications

- Automobile components

- Aerospace components

- Communication gadgets

Intellectual Property Development Indices (IPDI)

- Performance and stability validated at laboratory scale

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An improved abrasion resistant and hydrophobic composition for coating plastic surfaces and a process for its preparation, Indian Patent application number 1278/ DEL/ 2011 dtd 02-05-11

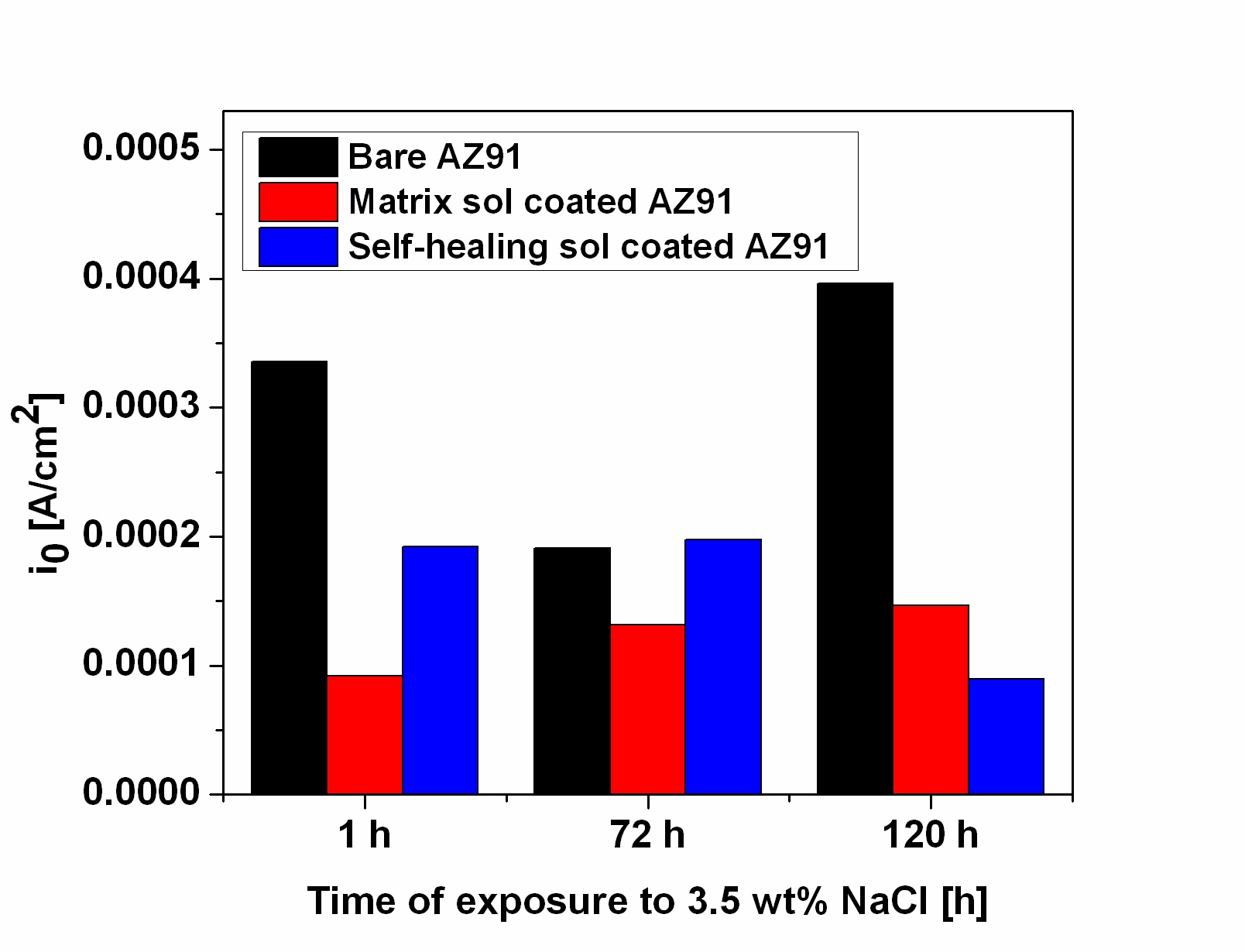

Self-Healing, Corrosion Protection Coatings on Al and Mg Alloys

Overview

Key Features

- Non-toxic and eco-friendly

- Amenable to coat large areas with easy automation

- Good adhesion to the substrate materials

- Can be applied as bond coat to promote adhesion of primers

- Can be made as Decorative coatings also

- Low temperature (≤130oC) curable

Potential Applications

- Aircraft bodies

- Automotive components

- Any Al/Mg alloy component

- Can be used as an additive in paints/primers to enhance corrosion protection

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated on coupons at laboratory scale

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An improved coating composition to provide prolonged corrosion protection to anodizable metal surfaces and process of preparing the same Indian Patent Application number 3082/DEL/2015 dtd 28-09-15.

- An improved composition for coating anodizing metal surfaces and a process of coating the same. Indian Patent Application number: 1310/DEL/2013 dtd 03-05-13.

- N. Kumar, A. Jyothirmayi, K. R. C. Soma Raju, V. Uma and R. Subasri (2013): One Step Anodization/Sol-Gel deposition of Ce3+-doped silica-zirconia Self- Healing Coating on Aluminum, ISRN Corrosion, article id 424805

Decorative Nanocomposite Coatings on Glass and Ceramics

Overview

There are principally two different methods to achieve intense colors in bulk glasses; one by incorporating transition metal cations into the glass network, which absorb visible light due to electronic transitions in their atomic orbitals and the other by addition of metal salts of Au, Ag or Cu, which are reduced to the metallic state during melting and segregate from the glass matrix while cooling. The colouring of glass via melting techniques has some unique problems with respect to reproducibility, toxicology during production & recycling and economics. When differently coloured bottles are mixed during the re-melting process for recycling, desired colours are very hard to obtain. Traditionally, the decoration of crystal glasses is performed by laborious manual techniques, which are costly and do not meet modern market requirements. Sol-gel coloured/decorative coatings are thin, low temperature curable, eco-friendly alternatives and are easy to recycle.

Key Features

- Tuneable transmission and refractive index of the coatings

- Colour of the coating can be controlled by suitable choice of dopants

- UV, temperature stable and weather proof

- Easy recyclability of glass due to complete degradation of organic constituents at low temperatures

- Opaque coatings possible with high temperature durability

Potential Applications

- Architectural applications: Coloured glasses/Tiles for aesthetics or decoration

- Scratch resistant, coloured coatings for glass bottles used in various industries for storing perfume, medicines etc

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up and large area performance evaluated

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- Sol-Gel Nanocomposite Hard Coatings, K.R.C. Soma Raju and R. Subasri in "Anti-abrasive nanocoatings: Current and future applications", (ed.) M . Aliofkhazraei, Woodhead Publishing (an imprint of Elsevier), UK, 2015, pp 105-136.

- R.Subasri, C.S.Madav, K.R.C.Somaraju and G.Padmanabham, “Decorative hydrophobic sol-gel coatings densified using near-infrared radiation” Surface and coating technology, vol 206 (8-9), p 2417-2421, 2012.