Centre for Fuel Cell Technology (CFCT)

3 channel Potentiostat/Galvanostat with RRDE

Model and Make

- VSP, Biologic Science Instruments

Specifications

- Current range: 10 µA up to 0.4A (760 pA resolution)

- 20 V adjustable reference voltage

- Resolution: 300 µV programmable down to 5 µV by adjusting the dynamic range

- Acquisition time: 200 µs

- Simultaneous EIS measurement

Details

The VSP provided with three channels is supplied with EC-Lab software package. The VSP chassis is designed to receive +/-10 A current booster option. The VSP can be outfitted with potentiostats capable of performing Electrochemical Impedance Spectroscopy (EIS).The frequency range is from 10 µHz to 1 MHz. Over 70 techniques can be sequenced, and with a variety of analysis tools, including EIS modeling with Levenberg Marcquardt and Simplex algorithms. Suitable for most electrochemical studies including corrosion studies, battery testing and intercalation compounds study.

Accelerated surface area pore analyser

Model & Make

ASAP2020; Micromeritics, USA

Specifications

Consists of two ports , one for vacuum and One for analysis with three transducers in the range 0-1,1-10 and 10-1000 mm of Hg, capable of measuring single and multi-point surface area, Adsorption-desorption isotherms, Micropore, Size distribution, meso and macro pore area, total pore volume, physisorption and chemisorption from room temperature to 450oC, standard software for automated operation

Details

The instrument is capable of measuring the surface area and pore size distribution from 3Ao to 5000Ao with the help of various analysis gases like N2, Ar, CO2,O2,Kr, Co and any non-corrosive Gases.

Centre

Centre for Fuel Cell Technology

Battery Cycler

Model & Make

BCS-815 model, Bio-logic SAS.

Specifications

- 8 channels with EIS facility

- Voltage range : 0 - 9 V with 40 µV (18 bit) resolution

- Maximum current : ± 15 A

- Maximum power : 100 – 110 W

- Frequency Range: 10 mHz – 10 KHz

- Acquisition time : 2 ms

- Potential Resolution : 40 µV

- Current Resolution: 20 nA

- All the channels are independent

Details

The BCS-815 battery cycler is the largest module available in the BCS-8xx line of instruments. All the channels can be operated in parallel to supply ±30 A, ±60 A or ±120 A for maximum hardware flexibility. Five current ranges between 10 A – 1 mA yield excellent resolution down to 20 nA (18 bit). Every BCS-815 module is equipped with a dedicated K-type thermocouple input on each channel to allow for temperature measurement on each cell. The BCS-815 instrument is controlled by BT-Lab software – a powerful software suite based on industry leading EC-Lab software. In BT-Lab, all of the main battery parameters are automatically processed and displayed on-line in real time. Up to 64 channels can be controlled by a single Communication Module, with expansion to larger systems as simple and easy as plugging in RJ45 cables.

Centre

Centre for Fuel Cell Technology(CFCT)

Capillary Flow Porometry

Model & Make

Porolux 1000; Porometer, Belgium

Specifications

- Operates with pressure transducers upto 35 bar

- Minimum pore size measurements: down to 18 nm.

- LabVIEW software

Details

Capillary flow Porometry is based on the displacement of a wetting liquid inside a porous network by means of an inert gas flow. With Porometry through pores inside a sample are characterised. Through pores are open on both sides of a filter or a membrane and therefore determine the functionality. The important parameters such as largest pores, the mean flow pore size and smallest pores of the sample can be determined.

Centre

Centre for Fuel Cell Technology

Contact Angle Measurement Unit

Model and Make

- DSA25 with temperature-controlled chamber, KRUSS, Germany

Specifications

- Zoom – 6.5 x, Manual

- Camera performance – 2000 fps at 90 x 60 px

- Dosing – Software Controlled

- Resolution – 0.1 µL with Glass syringe

- Tilting - External, 0-90°

- Temperature controlled chamber (-10 to 130 °C)

Details

Contact angle measurement gives an idea about the wetting ability of a material. The material can be metallic, non-metallic, coated or surface treated. Measured volume of a drop of liquid (in most cases, distilled water) is placed over the surface and the wetting ability is recorded by measuring the angle subtended by the drop on the surface of the material. This gives an idea about, the material, whether it is hydrophilic or hydrophobic in nature. Surface free energy of the solid can also be determined by making use of the contact angle measurements.

Cross Hatch Adhesion Tester

Model and Make

- Elcometer 107, ELCOMETER, USA

Specifications

- Cutter type - 6 x 1 mm

- Coating thickness - 0 to 60 µm / 0- 2.4 mils

- Adhesive tape - ASTM standard [ASTM D3359]

Details

Cross hatch adhesion test, or simply, tape test in one of the standard tests to rate the adhesion of coating on a material. Lattice pattern of cut is generated by the cutter by creating parallel lines and repeating the step at 90° to the first cut. A small portion of the tape is pasted on this pattern and removed in one-stroke at 180° to the sample. Detachment of the coating and presence of flakes in the tape, refers to poor quality of the coating. Absence of any, confirms to good quality of coating.

Dynamic Mechanical Analyzer

Model & Make

Q 800; TA Instruments, USA

Specifications

- Temperature: -150-600oC

- Frequency: 0.0001 to 200 Hz

- Force range:0.0001 to 18N

Details

The instrument is useful for measuring the stress-strain measurement, glass transition temperature measurements, tan? etc. for samples with low stiffness. Measurements with respect to controlled temperature, humidity and under submersion conditions are also possible.

Centre

Centre for Fuel Cell Technology

Electrochemical Galvanostat, Potentiostat, Frequency Response Analyzer

Details

Electrochemical system comprising Potentiostat, Galvanostat and frequency response analyzer is for characterization of fuel cell catalyst, fuel cell electrode , Fuel cell membrane and electrode assembly using the techniques-cyclic, pulse, AC voltammetry, chrono-amperometry/coulometry/potentiometry. The unit also has an accessory RDE to perform electrochemical hydrodynamic and impedance studies. The FRA is in low the low frequency range and suitable for low resistance materials.

Centre

Centre for Fuel Cell Technology

Environmental Chamber

Model & Make

VCS7027-10; Votsch, Germany

Specifications

- Two chambers viz., a climatic test cabinet and an air supply unit.

- Test space volume in the climatic test cabinet : around 1300 ltrs,

- Operatable temperature range: -40oC to +75oC

- Humidity range: 10% to 95% RH

- Dew point range: -3oC to +74oC

- Air flow in the Air supply unit: 2500 lpm in the set temperature range -40C to 50C in the humidity range 20 to 95% RH with dew point range 4C to 49C.

Details

The safety features include a flame detector, hydrogen sensor, emergency stop, auto lock etc., and monitoring sensors for oxygen, humidity and temperature. Air supply and humidity to this unit is through a dedicated screw compressor, chiller and a refrigeration unit. The units are controlled and monitored using SIMCON software which gives both digital display as well graphical representation of the data set and actual value with inbuilt memory and integrated programme generator.

Centre

Centre for Fuel Cell Technology

Four Probe Conductivity

Model and Make

- RM300, JANDEL, United Kingdom

Specifications

- Measurement range - 1 mohm/square to 500 Megohms/square

- Current - 10nA to 99.99mA, 0.3% across range

- Correction - Forward and Reversible current

- X-Y travel - 25 mm x 25mm

- Maximum sample area - 10" x 10" x 6" inches

- Sheet resistance measurement and Volume (Bulk) resistivity

Details

Four probe conductivity measurement gives the in-plane conductivity by the way of sheet resistance and in some cases, volumetric (bulk) resistivity of the samples. Difference in the sheet resistance of bare and coated samples, gives an estimate about the in-plane conductivity of the coating alone. Constant current is applied automatically, through two outer probes and the voltage developed with the other two probes is measured. The direction of the current flow can be reversed. The surface of the sample should be flat, for accurate measurements.

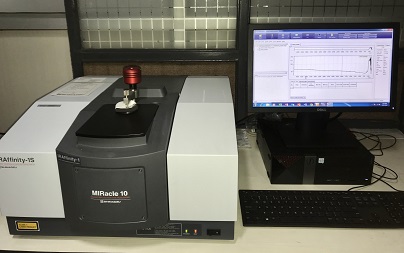

Fourier Transform Infrared Spectrophotometer (FTIR)

Model & Make

IR Affinity - 1S Fourier Transform Infrared Spectrophotometer, SHIMADZU.

Specifications

- Attenuated Total reflectance (ATR) facility with Zn-Se prism

- Sample dispersion in KBr pellets

- Scan range Mid IR region 400 - 4000 cm-1

- Resolution 1.0 cm-1

- Quantitative analysis of solids and liquids

Details

The instrument is useful for identification of functional groups in the sample and also with quantitative estimation.

Centre

Centre for Fuel Cell Technology(CFCT)

Fuel Cell Fabrication

A. Wet Ball Mill

Details

The planetary ball mills are used wherever the highest degree of fineness is demanded. Apart from the classical mixing and size reduction processes the unit meets the technical requirements for colloidal grinding and also have the necessary energy input for a mechanical alloying process.

PEMFC electrode development involves preparation of diffusion layer slurry and catalyst ink slurry for which a good homogeneous mixture of the ingredients with desired particles of uniform dimension is required. The material is normally soft and the medium can be wet or dry.

This equipment can also used for R & D purpose for different applications.

Centre

Centre for Fuel Cell Technology

B. Screen Printing Machine

Details

Different types of coating like brushing, spraying and painting are used for fuel cell electrode preparation. A screen printing machine is used for fabrication of electrodes with uniform thickness. This unit can also be used for adhesive coatings in gaskets being used in fuel cell assembly . This is a semi-automated process for electrode development, increases the production rate, and reduces the harmful exposure of organic solvents compared to other techniques.

Centre

Centre for Fuel Cell Technology

C. Hydraulic Hot Press

Specifications

- 4 posts

- 7" bore cylinder

- 42" lower platen operating height

- Temperature up to 500 F

- Adjustable daylight of 8-15"

- PID controller

- Pressure compensated hydraulic pump

- Water coolant,

- Heat exchanger

- Switch over from Manual to motorized operation.

Details

This equipment is used for the lamination of electrodes with electrolyte which are micron thick. The high precision in the platen surface, pressure and water supply makes the unit ideal for making MEAs with less interfacial resistance, thereby improve the catalytic activity.

Centre

Centre for Fuel Cell Technology

D. Ultrasonic Processor

Details

Ultrasonic processor with sonotrode(s) of different sizes are used in preparation of large volume of carbon and catalyst slurries used in fuel cell electrode fabrication.

Centre

Centre for Fuel Cell Technology

E. Ultrasonicator Bath

Details

This unit is selected for use during the process of making fuel cell electrodes when the catalyst ink and carbon ink have to be kept agitated and the particles are expected to be in the suspended state rather than settling down at the bottom.

Centre

Centre for Fuel Cell Technology

F. Vacuum Ovens and Sintering Ovens

Specifications

Operating temperature: upto 400oC

Details

Vacuum ovens and sintering ovens operating at different temperatures have been installed which are used at various stages in the processes of making electrodes. The sintering processes can be carried out at reduced pressure or nitrogen atmosphere which are required to avoid catalyst particles sintering, oxidation and ignition.

Centre

Centre for Fuel Cell Technology

Fuel Cell Impedance Measurement System

Model and Make

- Kikusui KFM 2150 system 5000 Multifunctional electronic load- 5kW

- Multichannel FC scanner- KFM 2151

Specifications

- Multifunctional electronic load- 1.5V-150V/1000A/5000W

- Impedance analyzer 10mHz to 20kHz

Details

Used to study impedance of a large PEMFC stack ( upto 5kW capacity). Scanner is capable of performing impedance analysis on each cell. It is helpful for giving real time information about internal cell behaviour and for identifying failures during operation of the fuel cell system.

Fuel Cell Test Benches

Details

In order to evaluate the fuel cell performance at different conditions of flow, pressure, humidity and temperature fuel cell test benches are used. Several fuel cell test benches for single cell testing, short stack testing and large stack testing have been installed. Some of this are automated with data logging facility. A fuel cell test bench consists of gas flow controllers for each gas, humidification bottles for humidifying the gases, temperature controllers for controlling the temperate of the humidification bottles as well as to heat the single cells, back pressure regulators to facilitate operating the cells at a particular pressure of the reactant gases and an electronic load box which can operate at high current (0-150 amps DC) and at low voltage (~0.1V DC). The fuel cell test benches are used to evaluate the single cell performance (current Vs Voltage at different operating conditions). These data are used to optimize/improve the electrode composition & electrode fabrication processes, to find the catalyst efficacy, to determine the membrane performance (when different membranes are used), in scaling-up the electrode area etc. The system has safety features with hydrogen sensors for hydrogen leak, low voltage, high pressure, low flow etc.

Centre

Centre for Fuel Cell Technology

Gas Chromatograph

Model & Make

Trace GC Ultra; Thermo Fisher Scientific, USA

Specifications

Facility is integrated with a methanator for detection and evaluation of trace amounts of CO and CO2 gases present in the reactant/ product stream of gases

Details

Gas chromatograph with TCD, FID and FPD detectors is used to analyse the exhaust gas from the fuel cell especially, when the fuel cell is operated with methanol and reformate gas.

Centre

Centre for Fuel Cell Technology

Gurley Permeameter

Specifications

Equipment suitable for air resistance 0 to 3 secs in the permeability range of 1 to 400 ft3/min/ft2 at a pressure drop 0.5" H2O column in the flow range of 0-400CFM.

Details

A gas permeability meter is used for the qualitative and quantitative measurements of the high permeability paper like substances such as the fuel cell electrodes at various stages.

Centre

Centre for Fuel Cell Technology

Hydrogen Generator

Model and Make

- Proton H series -Hydrogen Generation System

Specifications

- Nominal Production Rate

- Nm3/hr @ 25°C, 1 bar - 2 Nm3/hr

- SCF/hr @ 70°F, 1 atm - 76 SCF/hr

- SLPM @ 70°F, 1 atm - 35.8 SLPM

- kg per 24 hours - 4.31 kg/24 hr

Details

The H Series generators utilize PEM technology to produce ultra-high purity hydrogen (99.9995%) consistently on-site. The system consumes power to produce hydrogen at 15 barg (128psig) using water as reactant. It uses liquid cooling technology for thermal management of the system. Produced hydrogen can be stored in a cylinder at 15 barg, which can be utilized for Fuel cells testing purpose.

Keithley Nano Current Source and Voltmeter

Details

Measurement of conductivity requires a stable current source and a high precision voltage measuring device. Such a device is used to evaluate the surface as well as the bulk conductivity of the bi-polar plates used as gas feed as well as current collector in the fuel cell stack. These parameters are also used for quality control of the bipolar plates when made from composites. The Keithley digital source meter and the Keithley Nanovolt meter combination with data acquisition capabilities serves this purpose.

Centre

Centre for Fuel Cell Technology

Multichannel Electrochemical Test system

Model & Make

1470E; Solartron Analytical, UK

Specifications

- Multi-channel potentiostat & frequency response analyzers (FRAs) connected to a computer providing simultaneous DC and impedance tests on multiple cells.

- Eight fully independent potentiostat for eight separate cells to be tested simultaneously with the voltage and current range of +10V to -3V and 0 to 4 A.

Details

The Solartron Cell Test system is the most advanced Multi-channel battery, fuel cell, super capacitor test system Available, giving the ultimate in DC and impedance test Performance. The speed, range and resolution of the Cell Test system also makes it suited to other research applications including the analysis of sensors, coatings, corrosion and general electrochemical applications. Each channel is completely independent allowing the same or quite different experiments to be run on each cell. The Cell Test system provides a wide range of experimental techniques, including charge / discharge, potentiostatic, potentiodynamic, galvanostatic, galvanodynamic, fast cyclic voltammetry, open circuit, fast pulse and step techniques, ohmic-drop analysis and impedance.

Centre

Centre for Fuel Cell Technology

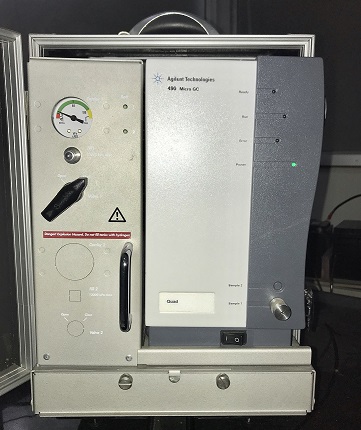

Online Micro GC For The Analysis Of Gaseous Products

Model & Make

490 Micro GC, Agilent.

Specifications

- 4 channels equipped with carrier gas sampling valves, sample inlet with filters, heated injector with back flush option, column and detector.

- Column 1: Molseive 10m, heated back flush RTS

- Column 2: PPQ 10m, heated back flush

- Column 3 : CP-Sil-5CB 8m, heated

- Column 4 : Cox 1m, heated back flush

- Field test setup comprising of field case, carrier gas cylinder, battery pack and charger.

- Power requirements: 230 V/50 Hz.

Details

Online unit integrated with 4 channels with a TCD detector for the analysis of different gaseous products including acetaldehyde, formaldehyde, carbon dioxide, carbon monoxide, methyl mercaptam, methane, NO, nitrogen, oxygen and hydrogen etc with analysing capacity of above 1 ppm.

- Channel 1: CH3CHO, HCHO, CH3SH, CH4 and other hydrocarbons

- Channel 2: CO2, CH4, and N2O

- Channel 3: CH4, NO, CO, H2, O2, and N2

- Channel 4: Moisture tolerance column for CO, CO2, H2 and CH4

Centre

Centre for Fuel Cell Technology(CFCT)

PEM Fuel Cell Automated Test Station

Model and Make

- Green Light G60, Green Light Innovation.

Specifications

The G60 is available with several advanced Testing techniques.

- Emerald control software for fully automated operation with Advanced Scripting Language.

- Load Box: max. load 625W, max. current 125A, max. voltage 5V.

- Load Box Modes: CC, CV or CP (constant Current, voltage or power)

- Max. Gas Flow: H2 3 NLPM, Air 20 NLPM, O2 5 NLPM, N2 5 NLPM, Methanol 75ml/min

- End Plate Heater control: Anode/Cathode PID controller.

- Humidification System: Gas Temperature 1100C, Dew point Control up to 900C

- Gas Detector: One H2 gas detector

- Back Pressure control: up to 500KPa

- EC Load Box: Gamry Interface 5000E

- Electrochemical Studies: Cyclic Voltammetry (CV), Electrochemical Impedance Spectroscopy (EIS).

- Test Bench Area: 710 mm×480 mm (28×19)inches

Details

G60 is Fuel Cell Automated Test Station system (FCATS) with a closed loop control system and emerald scripting software allowing the test station to run performance, durability tests and diagnostics of the fuel cell systems. EIS, CV studies are done by using Gamry Interface 5000E. There is an optional DMFC mode configuration with a Methanol and H2O mixture.

Powder Xray Diffractometer ( XRD)

Model and Make

- Smart Lab X-Ray Diffractometer , Rigaku

Specifications

- Sealed tube generator with Rotating anode generator

- Maximum rated output: 3 kW

- Rated tube voltage - current : 20 - 60 kV; 2 - 60 mA

- Target Cu (others: optional)

- Focus size: 0.4 x 12 mm line/point (others: optional)

- Radiation enclosure: Full safety shielding with fail safe open/close mechanism

Details

The high-resolution X-ray diffractometer provided with SmartLab Guidance software, acts as an intelligent interface for the user. The system incorporates a high resolution θ/θ closed loop goniometer drive system, cross beam optics (CBO), an in-plane scattering arm, and an optional 3.0 kW rotating anode generator. High flexibility by coupling a computer controlled alignment system with a fully automated optical system makes it easy to switch between hardware modes. Optional in-plane diffraction arm for in-plane measurements without reconfiguration and focusing and parallel beam geometries without reconfiguration.

Scanning Vibrating Electrode Technique (SVET)

Model & Make

- VersaSCAN, AMETEK, USA

Specifications

Lock-in Amplifier

- Noise Sensitivity : 13fA per second

- Frequency Range : 1 mHz up to 250 kHz

- Full Scale Sensitivity : from 10nV to 1V

- DSP Stability : Impervious to temperature drift

- Piezo : up to 30 microns vibration perpendicular to sample surface

- Gain : from 1x to 10,000x in decades

- Material : Pt/lr, Single-element probe

Electrometer

Probes

Details

The Scanning Vibrating Electrode Technique uses a single wire to measures voltage drop in solution. This voltage drop is a result of local current at the surface of a sample. Measuring this voltage in solution images the current at the sample surface. Current can be naturally occurring from a corrosion or biological process, or the current can be externally controlled using a Galvanostat. A piezo unit vibrates the probe in Z-direction (axis parallel to the sample). The amplitude of vibration may be only 10s of microns peak-to-peak. This small vibration provides a very small voltage to be measured. Therefore, the response (signal + noise) at the probe is then gained by the electrometer. The gained output of the electrometer is then input to a Lock-In Amplifier. This, in turn, uses a phase detector along with a Reference at the same frequency of vibration to extract the small AC signal from the entire measured response.

Scanning Electro-Chemical Microscope

Details

Scanning Electrochemical Microscopy (SECM) is an electrochemical-cum-analytical technique that allows to map the topography of the electrode surface during electrochemical oxidation/reduction reaction that takes place at the interface of the electrolyte/electrode. An ultra-micro electrode at the tip of the probe allows the visualization of spatially-confined variations in the chemical reactivity depending on the surface conductivity of the electrode, using , amperomertric or potentiometric techniques as in the case of normal potentiostat/galvanostat.

Centre

Centre for Fuel Cell Technology

Scanning Electron Microscope

Model and Make

- Scanning Electron Microscope SU1510, Hitachi

Specifications

- Resolution SE & BSE: 3.0 nm at 30 kV (High Vacuum Mode),4.0 nm at 30 kV (Variable Pressure Mode)

- Magnification: x5 to x300,000

- Accelerating Voltage: 0.3 to 30 kV

- Electron Gun: Electron Gun

- Detectors: Secondary Electron Detector, High Sensitivity Semiconductor BSE Detector

- Image Data Saving: 640 x 480 pixels, 1,280 x 960 pixels, 2,560 x 1,920 pixels, 5,120 x 3,840 pixels

Details

Medium size chamber variable pressure SEM with Quad Bias gun electronics which improves low voltage performance and increases beam the current. Dual high-take-off ports accommodate two EDS detectors mounted 180 degrees apart to tice the analytical data collection plus eliminate X-ray map shadows associated with rough sample surfaces. A high speed, clean, efficient TMP eliminates the need for water cooling. Advantages of being compact, high performance and user friendly. For quick observation of non-conductive samples the SU1510 utilizes variable pressure mode that eliminates negative charging, and provides the optimum conditions for both imaging and Energy Dispersive X-ray microanalysis. The specimen chamber and stage have been designed to accommodate samples as large as 153 mm in diameter. Simultaneous EDX microanalysis and imaging can be completed on a sample that is up to 60mm in height at the analytical working distance of 15 mm.

Sieverts apparatus

Model & Make

Advanced Materials Corporation, USA

Specifications

- Temperature range: -260oC to 500oC with different sample holders

- Automatic pressure range switching available between high and low pressure transducers : 0.001 to 200 bar

Details

Used to study the hydrogen absorption in metals, alloys and carbon based materials in the pressure range from vacuum to high pressure (200 bar) on multiple volumes to tackle a wide variety of applications. Designed to work on Powders, hydrogen storage materials, catalysts, on Fibers (carbon), on thin films , liquids etc. The software is Capable of executing automated processes for System preparation, sample preparation and 4 types of measurements (kinetics, PCT, Cycling kinetics and Cycling PCT). It has enhanced safety that includes flammable gas detection sensor for hydrogen and continuous monitoring of over temperature.

Centre

Centre for Fuel Cell Technology

SOFC Test Bench

Model & Make

SMART 2 Dolphin; WonATech, South Korea.

Specifications

Capable of accommodating 4 types of anode gases , electrical furnace which can go up to 1000oc, removable and split type, bubble type humidifier, electronic load up to 50 watts.

Details

Fully automated test bench is used for evaluating planar type SOFC cells of 25 mm dia with provision for compressive loads, measurement of i-v characteristics in combination with EIS studies. The instrument has safety features for hydrogen detection, low water level, and high temperature alarm, emergency stop etc., The instrument comes with dedicated software to study the SOFC single cell performance, electrochemical measurements and EIS studies.

Centre

Centre for Fuel Cell Technology

Thermogravimetry Analyser with Mass Spectrometer

Model & Make

STA 4497,QMS403C; NETZSCH, Germany

Specifications

- Capable of loading up to 2g

- Maximum temperature of 1000C with heating rates from 0.1 to 80K

- Controller for data acquisition, temperature and gas flow control.

Details

It consists of a vacuum-tight thermo micro balance system, microprocessor-controlled, with integrated calibration weight, with water-cooled heater, exchangeable sample carrier including radiation shield, programmable gas flow for 3 gases and integrated heating power supply, automated lid lifting device (prepared autovac for automated vacuum generation/ventilation). This instrument comes with QMS coupling for evolved gas analysis from 1-300 amu and a processing module of the Aeolos software (as of version 7.02), enabling a triggered start and stop as well as the transfer of the temperature signal into the Aeolos software for programming and control. unit for data acquisition and processor of max. 64 measuring channels (mass and mass range resp.)

Centre

Centre for Fuel Cell Technology

THICKNESS INDUCED RESISTANCE MEASUREMENT - INTERFACIAL CONTACT RESISTANCE (ICR measurement)

Model & Make

SHIMADZU AGS-10x with ESA amplifier, Japan

Specifications

- Force capacity - 5000 N

- Crosshead travel - 1200 mm

- Extensometer - Strain guage – contact type

- Resolution - 0.001 N in Load, 1 micron in Extensometer

- Load Cell - S-series

- Temperature of operation - RT

Details

Interfacial Contact Resistance measurement of various components of the fuel cell such as coated metallic bipolar plates with the GDL can be measured with the above equipment. Though in principle, it is nothing but a press with 5kN load cell, the setup is customized for measuring the ICR of the samples and this is directly affected by the coating material, thickness of the coating/substrate. ICR affects the overall performance of the fuel cell. Precise measurement of ICR under uniform/non-uniform compression is required to assess the performance of fuel cell stack.

Centre

Centre for Fuel Cell Technology

Ultrasonic Spray Coating Prism -500

Model & Make

Ultrasonic Spray Coating prism -500, Ultrasonic Systems, Inc

Specifications

- Ultrasonic generator range 35-48 KHz.

- Dual mode CAT –ILDS nozzle-less Ultrasonic Spray Head.

- Precision metering liquid delivery system capacity of 100 ml.

- Application Area (X,Y,Z) 450mm x 500mm x 100mm.

- Air Pressure required 80 PSI, clean, dry air at 5 SCFM

- Substrate Heater (1500C).

- 95-99% transfer efficiency.

Details

Nozzle-less ultrasonic spray coating prism 500 is a high-performance X-Y-Z motion and positioning platform ideal for the thin and uniform, defect-free application of a variety of conformal coatings. The Prism 500 is configured with a PMP liquid delivery system coupled with a Micro-Line Digital Dispensing Valve and Dual-Mode Spray Valve. A teach Mode, laser pointer and an offline programming tool have been used to increase the ease of creating coating recipes. The teach mode option is fully integrated with the Prism graphical user interface (GUI) for seamless programming and process verification. Electrodes with any area fitting in a dimension of 5mm x 5mm to 450mm x 500 mm can be coated.

Centre

Centre for Fuel Cell Technology(CFCT)

UV lamp

Model and Make

- Omnicure S1000, Lumen Dynamics, Canada

Specifications

- 100 Watt UV light source with wavelength range 320 - 500 nm and intensity (power) adjustment facility.

Details

High-pressure Mercury vapour lamp as UV source; Electronic shutter with interlock; 999 second automatic timer; Fiber optic waveguide. Used for Photo-electrochemical water splitting experiments and UV assisted graphene synthesis.

UV-Vis spectrometer

Model and Make

- Ocean Optics, Germany (GmbH)

Specifications

- DT-MINI-2GS as UV-VIS-NIR light source with USB 2000 detector

Details

Equipped with Fibre optic waveguide; used for optical absorption, transmission spectroscopy for liquid and thin film samples on glass substrate

Zeta 20 3D Optical Profiler

Model and Make

- Zeta 20 3D Optical Profiler, ZETA Instruments.

Specifications

- 5x, 20x,100x standard objective magnifications are available.

- ZDot innovative 3D imaging is standard in optical profilers. The ZDot technology with unique transmissive and dark field illumination schemes as well as a variety of objectives allows the tool to handle the most ‘difficult’ of surfaces.

- ZIC enhanced differentials interference contrast imaging is great for nano- meter level surface Roughness.

- ZSI shearing interferometer provides Angstrom level vertical resolution.

- ZX5 vertical scanning interferometry is ideal for measuring nanometer heights to over large field of view

- ZFT reflectometry based thin film thickness measurement option.

Details

The Zeta-20 Optical Microscope is a fully integrated microscope based system that provides 3D imaging and metrology capability in a small, robust and cost effective package. Based on proprietary technology, the Zeta-20 images and analyses the surface features on samples of all smooth to rough, low reflectivity to high reflectivity, transparent to opaque.

.jpg)