Centre for Fuel Cell Technology (CFCT)

Electrochemical Synthesis of Lithium Aluminium Hydride an advanced Propellant Ingredient

Overview

In recent years, high performance solid propellant has been a great deal of attention in the area of high energy materials research field. Development of a high performance solid propellant will be achieved by using high energy density materials such as metal hydries. Among the metal hydrides, aluminium Hydride, AlH3, commonly known as alane is the most interesting fuels for propulsion, because of its ability to substantially increase the performance of a given system. The typical formation route of alane is through the chemical reaction. It involves high pressure operation and formation other by products like metal halide. For these reasons, our research attempt has been initiated in a more economically and thermodynamically cost effective synthetic and regeneration route to produce alane by electrochemical method.

Key Features

- Avoid the impractical high pressure needed to form AlH3

- Avoid chemical reaction route of AlH3 that leads to the formation of alkali halide salts such as LiCl or NaCl

- Utilize electrolytic potential to translate electrochemical potential into chemical potential and drive chemical reactions to form AlH3

Potential Applications

- As an additive in solid propellant

- On-board Hydrogen Storage

Intellectual Property Development Indices (IPDI)

- Setting up electrochemical facility for synthesis of alane

- Preliminary single cell studies for alane preparation.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Aluminium Hydride as an advanced propellant Ingredient- A synthesis perspective G.T.Harini, T.Ramesh R. Balaji, N. Rajalakshmi, V. Venkatesan, S.Nandagopal . Paper Presented at Advanced Materials and Processes for defence applications (ADMAT19) on Sep 23-25’2019 at Hyderabad

Electrochemical Methanol Reformation (ECMR) for Hydrogen Generation

Overview

The successful commercialization of Fuel cell technologies requires steady hydrogen supply. Steam Reformation of hydrocarbons and electrolysis of water are commonly available methods to produce hydrogen. However steam reformer works best in higher capacity systems, while the electrolysis requires more energy input for splitting water to hydrogen and oxygen due to its high over potentials. CFCT has now developed a method which combines aspects of both the processes to produce hydrogen from methanol - water mixture. The Centre has developed and demonstrated of a hydrogen generator of 1 Nm3 hydrogen per hour capacity. Currently, the development of 2.5 Nm3/hr PEM based ECMR with improved performance and reduced cost is under progress.

Key Features

- Energy consumption for Hydrogen production was found to be low, about 1/3rd of water electrolyzer.

- Hydrogen can be produced at much lower temperature and pressure, unlike methanol reformer

- The hydrogen produced is highly pure and Hydrogen separation steps are not required.

- Carbon based materials can be used for stack fabrication

Potential Applications

- ECMR can be integrated with renewable energy sources like wind, solar to store the energy in the form of hydrogen and it can be used in fuel cells.

- In Power station as coolant

- In Semiconductor industry as a reducing agent

- Meteorological Department (hydrogen as a lift gas to fill weather balloons.

Intellectual Property Development Indices (IPDI)

- Scaled-up from single cell to stack and prototyp system developed and demonstrated

- Performance was tested for extended duration at laboratory

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Exfoliated Graphite separator based Electrolyzer for Hydrogen generation”. K.S.Dhathathereyan, R.Balaji, K.Ramya, N.Rajalakshmi, L.Babu, R.Vasu, P.Sarangan, R.Parthasarathy, Indian Patent Application no. 3073/DEL/2013.

- Method of preparing gas diffusion layer for the electrode of ECMR cell for hydrogen generation” R.Balaji, N.Rajalakshmi, K.Ramya, R.Vasudevan, K.Sudalayandi, Indian Patent Application No: 201911030852

- Influence of ethyl acetate as a contaminant in methanol on performance of Electrochemical Methanol reforming (ECMR) for hydrogen production. N.Manjula, R.Balaji, K.Ramya, N.Rajalakshmi K.S.Dhathathereyan, A. Ramachandraiah, Int. J.Hydrogen Energy, 43(2) 2018, 562-568.

- Electrochemical methanol reformation (ECMR) using low cost sulfonated PVDF/ZrP membrane for Hydrogen Production,N.Manjula, R.Balaji, K.Ramya, N.Rajalakshmi K.S.Dhathathereyan, A. Ramachandraiah, Journal of Solid State Electrochemistry, Vol.22, P 2757-2765, 2018.

- Nitrogen doped graphene supported Pd as hydrogen evolution catalyst for electrochemical methanol reformation” Manjula Narreddula, R. Balaji, K. Ramya, N. Rajalakshmi, A. Ramachandraiah. Int. Journal of Hydrogen Energy, Vol.44, P4582-4591,2019.

- Hydrogen Production by Electrochemical Methanol Reformation using Alkaline Anion Exchange Membrane based cells. Manjula Narreddula, R. Balaji, K. Ramya, N. Rajalakshmi Int.J.Hydrogen Energy, Vol.45, P 10304-10312, 2020

- A Polymer Electrolyte Membrane (PEM) cell and a method of producing hydrogen from aqueous organic solutions in pulse current mode” K.S.Dhathathreyan, R.Balaji, K.Ramya, N.Rajalakshmi. Indian Patent Application no. 3313/DEL/2012

- Studies on development of Titanium oxide Nano Tube (TNT) based ePTFE–Nafion–composite membrane for electrochemical methanol reformation, N.Manjula, R.Balaji, K.Ramya, K.S.Dhathathereyan,A.Ramachandraiah Int. J.Hydrogen Energy, 41 2016, 8777- 8784. 3.

- Palladium Nanoparticles as Hydrogen Evolution Reaction (HER) electrocatalyst in Electrochemical Methanol Reformer K. Naga Mahesh, R. Balaji, K.S. Dhathathreyan. Int.J.Hydrogen Energy 41, 2016, 46-51

PEM Fuel cell powered materials handling devices

Overview

One of the major application domains that have emerged in recent years is the use PEM Fuel cells in materials handling devices such as forklifts. This industry is rapidly adopting fuel cells because of their life-cycle cost and productivity advantages over batteries. Hydrogen fuel cell-powered equipment needs refuelling once or twice daily, depending on use. Fuel cell provides consistent power strength during use and does not experience decreased performance unlike batteries which require battery change out or recharge time. The challenges include fabricating fuel cell stacks with high performance and small foot print/volume, developing a closed loop thermal management system to operate the fuel cell stacks for long duration, power electronic units which deliver constant voltage, and system integration and packaging so that the fuel cell system with all its BoP and hydrogen supply unit fits in the space available in the forklift.

Key Features

- Air cooled/ closed loop liquid cooled PEMFC stacks to be developed .

- PEMFC stacks with reduced weight and volume would be developed Control system development for the battery fuel cell hybrid system.

- PEMFC stack would operate optimum efficiency at variable operating loads.

Potential Applications

- Application in material handling devices like Forklifts

- Application in recreational vehicles like Go Karts, Golf- Carts etc.

- Power source for all mobile applications.

- Power source for auxiliary units in mobile applications.

Intellectual Property Development Indices (IPDI)

- Air cooled stacks of capacity 1kW developed.

- Liquid cooled stacks with close loop cooling developed for 5kW PEMFC power for vehicular applications

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- A Grid Independent Fuel Cell system with a unitized (Dc&AC) power conditioner, N.Rajalakshmi, K.Ramya, R.Balaji, S.Bharathi, K.Sanjeev, K.Ranjan,M.M.Ramakrishna,Indian Patent Application No: 201911006700

- Method of preparation of carbon supported platinum electrocatalyst for proton exchange membrane fuel cells, N.Rajalakshmi, Raman Vedarajan, J.A. Prithi, Patent Application no. 202011035825.

- K Hari Gopi, Ashwin Nambi, N Rajalakshmi, Design and development of open cathode PEM fuel cell - Flow analysis optimization by CFD, Fuel Cells 2020, 20, 33-39.

- A Device for and A Method of Cooling Fuel Cells, K.S.Dhathathreyan, N. Rajalakshmi, B. Viswanath Sasank , Indian Patent Application no. 1409/DEL/2012

- B.V. Sasank, N. Rajalakshmi and K.S. Dhathathreyan,"Design and Optimization of a Closed Two Loop Thermal Management Configuration for PEM Fuel Cell using Heat Transfer Modules", International Journal of Chemical Engineering and Applications, Vol. 3( 3), p 243-248, 2012.

- K. S. Dhathathreyan, N. Rajalakshmi, K. Jeyakumar and S. Pandiyan, "Forced Air Breathing PEMFC Stack", International Journal of Electrochemistry, Vol. 2012, Article ID 216494, 2012, doi:10.1155/2012/216494, 2012

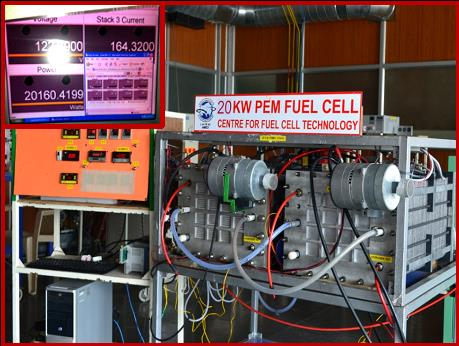

PEM fuel cell based power supply systems

Overview

Fuel cell are considered to be an ideal choice for power generation as the green house gas emission issues are considerably reduced.PEM Fuel cells are ideally suited for decentralized power generation due to their fast start up, modular nature and low start up temperature. The technological challenges include developing high performance fuel cell stacks and BoP components like the power conditioners, thermal management system etc. The successful commercialization of Fuel cell technologies requires steady hydrogen supply and development automated methods for key components fabrication. One of the aspects that is proposed to be undertaken is improved manufacturing methods . Rapid prototyping or Additive manufacturing has been considered in this project as the conventional methods of making the fuel cells is lengthy with lot of wastage.

Key Features

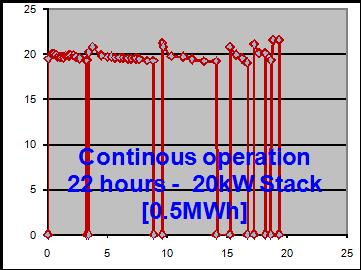

- Developed Grid Independent fuel cell systems in the range of 1-20kW power.

- PEM Fuel cells developed have been continuously operated for 500 hrs and intermittently for several thousand hours with stable performance.

- Suitable control systems for load following cycle, cell monitoring characteristics, power conditioners and thermal management have been developed.

Potential Applications

- As decentralised power pack for homes, industries etc.

- As combined heat and power units for homes

- As uninterrupted power source even when the power outage is for long duration ( >8hrs)

- As back up power for telecom industries.

Intellectual Property Development Indices (IPDI)

- Scaled-up from single cell to stack and prototype system developed and demonstrated

- Performance was tested for extended duration at laboratory and industrial environment

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Sreeraj P, Raman Vedarajan, N.Rajalakshmi, Venkatasailanathan Ramadesigan, Screening of Recycled Membrane with Crystallinity as a Fundamental Property, International Journal of Hydrogen Energy

- An Improved Test Control System useful For Fuel Cell Stack Monitoring and Controlling, K.S. Dhathathreyan,N. Rajalakshmi, Indian Patent application no. 269/DEL/2013

- A Method of Preparation of Supported Platinum Nano Particle Catalyst in Tubular Flow Reactor Via Polyol Process, K S Dhathathreyan, N Rajalakshmi, K N M Krishna, 1571/DEL/2013

- S. Pandiyan, K. Jayakumar, N. Rajalakshmi and K. S. Dhathathreyan, "Thermal and Electrical Energy Management in a PEMFC Stack - An Analytical Approach", International Journal of Heat and Mass Transfer, Vol. 51(3-4), p 469-473, 2008

Development of Electrically Rechargeable Zinc-air Battery

Overview

Electrically rechargeable Zinc-air batteries exhibit high specific energy and interesting from an economical and ecological point of view. One of the challenges with Zn-Air batteries is to make them rechargeable in aqueous based system. Scientists at CFCT are addressing this issue and have initiated a program to develop rechargeable Zn-air battery and eventually other metal - air batteries. In the first instance, we have developed and demonstrated rechargeable 12 V Zn-Air battery using air breathing electrodes and ionic liquid electrolyte. The cyclic stability studies were also reported. Presently CFCT has initiated work on development of aqueous electrolyte based rechargeable Zinc-air secondary battery and carried out preliminary studies. The electrode area of the cell has been scaled up from 5 sq.cm to 30 sq.cm and results shows improved cycle life and capacity of the cell and it has provided the scope for further improvement, which is in progress.

Key Features

- High Energy Density

- Materials are low cost, non-toxic and environmentally friendly.

- Easy fuel storage

- Non-flammable and non-explosive nature

Potential Applications

- Smart and green grid storage

- Automobile (Electric Vehicle)

- Portable

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at single cell level

- Scale-up and prototype module fabrication underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Karajagi, I., Ramya, K., Ghosh, P. C., Sarkar, A., Rajalakshmi, N., (2020) Nickel Integrated Carbon Electrodes for Improved Stability, Journal of Electrochemical Society 2020 167 130510.

- Karajagi, I., Ramya, K., Ghosh, P. C., Sarkar, A., Rajalakshmi, N., (2020) Co-doped carbon materials synthesized with polymeric precursors as bifunctional electrocatalysts, RSC Adv 2020,10, 35966-35978.

- Karajagi, I., Ramya, K., Ghosh, P. C., Sarkar, A., Rajalakshmi, N., (2019) . Ion Immobilized Bifunctional Electrocatalyst for Oxygen Reduction and Evolution Reaction, ACS Appl. Energy Mater. 2019, 2, 11, 7811-7822.

- Karajagi, I., Ramya, K., Ghosh, P. C., Sarkar, A., Rajalakshmi, N., (2019) Engineering of O2 Electrodes by Surface Modification for Corrosion Resistance in Zinc-Air Batteries, Springer Proceedings in Energy pp 717-723,Springer.com/gp/book/9789811559549.

- N.Sasikala, K.Ramya, K.S.Dhathathreyan, Bifunctional electrocatalyst for oxygen/air electrode Energy Conversion and Management. 77, 2014, 545-549.

Development and Manufacturing of metallic Flow field Plates for PEM Fuel cells

Overview

PEMFC technology has already been demonstrated in portable, stationary power, transport and several niche applications. For large scale commercialization technological advances are needed interms of cost reduction and manufacturing methods for producing some of the components. The major cost components are bipolar plates, catalyst and membrane. Bipolar plates facilitates the distribution of the reactants to the electrodes and presently constitutes about 50% of the cost ( for graphite plates ) and 75% of the weight and volume. Alternative materials to graphite and its composites are SS based metallic flow field plates which is likely to reduce the weight and volume by more than 50% as they can be made thinner unlike the graphite / carbon composite plates. The major challenge in developing the metal flow field plate lies in forming a complex flow field design on both sides of the plate for the supply of reactants and bond them together for proper sealing in case of multiple cells. An earlier study by ARCI led to the development of bipolar plates based on exfoliated graphite which reduced the machining cost of making bipolar plates.

Key Features

- Develop metallic bipolar plate by hydroforming technique with an industry partner after flow field and die design optimization

- Study of its corrosion properties under fuel cell conditions

- Development of suitable seals for optimum contact and prevent leakage of reactant gases.

- Development fuel cells and performance optimization at single cell and stack level.

Potential Applications

- Light weight PEMFC stack for vehicular applications

Intellectual Property Development Indices (IPDI)

- Corrosion studies on various coated and bare metallic plates being studied.

- SS based bipolar plates stack was developed using conventional technology for development of seals.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- An Improved Process for the Preparation of Exfoliated Graphite Separator Plates useful in Fuel Cells, the Plates Prepared by the Process and a Fuel Cell Incorporating the Said Plates, K.S. Dhathathreyan,N. Rajalakshmi,S. Pandiyan patent application no. 1206/DEL/2006

Smart Hydrogen Supply Chain Supported Polymer Electrolyte Membrane Fuel Cell in Telecom Tower Power Backup

Overview

Key Features

- Demonstration of an indigenous PEMFC system based power backup for telecom tower application.

- Feasibility of geographically specific hydrogen supply chain Bottled hydrogen / Reformed hydrogen / Renewable hydrogen

- Demonstration of PV integrated electrochemical methanol reformer as a hydrogen source which will be first of its kind internationally

- Technology Readiness Level change from 5-6 to 7-8 owing to the field trails and industrial partnership leading to the technology adoption for commercial application.

- Demonstration of Hydrogen as a vector for energy storage

Potential Applications

- Provide the best option for cost effective hydrogen supply chain for PEMFC based back up power for telecom applications

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Electrochemical Methanol Reformation (ECMR) for Hydrogen Generation

Overview

Key Features

Potential Applications

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

Setting up of Automated PEM Fuel Cell component/stack assembly Line

Overview

Key Features

- Development of automated pilot line with Indian collaborator to realise indigeneious development.

- Development of PEMFC stacks with more indigeneious components.

- Establishment of this facility is first of its kind in India.

- Provide simplification for mass manufacture of components/stack

Potential Applications

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

-1.jpg)

-1.jpg)

-2.jpg)

-1.jpg)