Centre for Advanced Powder Metallurgy (CAPM)

100 Tonne Spark Plasma Sintering

Model and Make

- Model: SPS-7.40MK-VI, Fuji Electronic Industrial Co. Ltd, Japan

Key Features (purpose / Advantage of using the equipment)

The spark plasma sintering (SPS) process is the most advanced form of sintering where it is possible to retain submicron structures at low sintering temperatures and short times. The difference between SPS and other sintering methods has ramifications in process efficiency and energy savings as well as microstructural and compositional implications. These beneficial effects have been largely attributed to a) the higher heating rates, b) imposition of an electric field and c) applied stress during sintering.

Specifications

- Current: upto 15 kA,

- Voltage: upto 10V

- Load: 1000 kN

- Campact size: 100 mm dia max

- Vacuum level: upto 6 x 10-5 mbar

- Molds: graphite

Centre

Centre for Nanomaterials

Battery Test Equipment

Model & Make

BT-2000, Arbin Instruments

Specifications

- Serial No: 166347

- Dimensions (W xL xH, inch): 14 x30 x25

- Channels: 20 Nos.

- Current range:

- Low: -100 µA ~ 100 µA

- Medium: -0.0005A ~ 0.0005A

- High: -0.005A ~0.005A

- Voltage Range: 0 V ~ 10 V

- Maximum Power: 0.05 W

Details

Arbin Instruments BT-2000 is a multi-channel testing system designed for R& D and production of batteries and other electrochemical energy storage devices. Each channel operates independently of each other enabling users to run tests on multiple batteries at the same time.

The features of Arbin Instruments BT-2000 are (i) completely independent channels allow users to run multiple independent tests simultaneously without affecting the other channels, (ii) accuracy up to 0.02% for low power and 0.05% for high power applications, (iii) Potentiostatic/Galvanostatic stations fine-tuned for battery Research & Development, and (iv) Up to three current ranges per station available for improved accuracy over a wide range of testing conditions.

Centre

Centre for Nanomaterials

BET Surface Analyzer

Model & Make

(11-2370)Gemini, Micromeritics, USA

Specifications

- Surface area determination limits : 0.1 m2 to >300 m2

- Sample quantity : Sample capacity is approximately 2.0 cm3

- Temperature : 10 to 350oC operating, 0 to 50oC non-operating

- Humidity : 20 to 80 % relative, non-condensing

- Gases : Optimized for nitrogen in a liquid nitrogen sample bath. Typically, oxygen, argon, butane, Methane and other light hydrocarbons.

Details

Surface area and porosity are important characteristics, capable of affecting the quality and utility of many materials. For this reason it is important to determine and control them accurately. BET theory of physical adsorption to form a monolayer of gas molecules on a solid surface is the basis for measurement of the specific surface area. The salient features are low surface area measurement capability up to 0.01 m2/gm with nitrogen, measurement of pore volume < 4.0 to 10-6cc/gm and higher, automatic free space correction unique twin tube design, data capability of single and multi point BET surface area.

Centre

Centre for Nanomaterials

Break Down Voltage Tester (DC and AC)

Model & Make

Custom made

Specifications

- Voltage rating for AC: 0-10kV±0.02

- Current rating for AC: 0-100m±0.02

- Voltage rating for DC: 0-5kV±0.02

- Current rating for DC: 0-50m±0.02

Details

The system can be used to measure the resistivity of the materials by changing current and voltage.

Centre

Centre for Nanomaterials

C-S Analyzer

Model & Make

CS - 444, LECO, USA

Specifications

- HF-400 induction furnace (18 MHz, 2,2 kW) for CO2/SO2 conversion

- Measured carbon in the range 0 to 0.5 %,

- Measures sulphur in the range 0 to 0.35 %

Details

Carbon/Sulphur system is a microprocessor based software driven instrument for wide range measurement of Carbon and Sulphur content of metals, ores, ceramics and other inorganic materials. It uses HF-400 induction furnace (18 MHz, 2,2 kW) for CO2/SO2 conversion. It works on the principle of infrared absorption of CO2 and SO2.

Centre

Centre for Nanomaterials

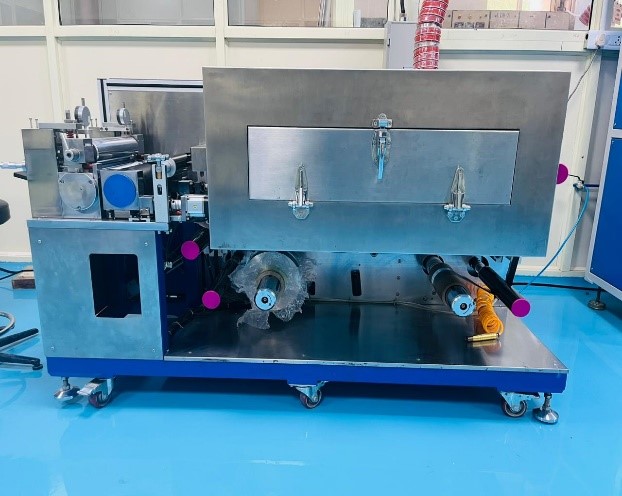

Calendaring machine

Model and Make

- GN HR200, Gelon LIB Co Ltd. China.

Specifications

- Roller size: 96 mm dia,

- Roller width: 200mm

- Roller surface max. temperature: 130 oC

- Calendaring thickness: 0-2 mm, Adjustable

Details

The calendaring is an important step in the cell fabrication. The dried electrode foils after the coating have to be pressed using a calendaring machine to get desired porosity of the electrode. The gap between the rollers can be adjusted to a desired thickness.

Carbon-Sulphur Analyzer

Model and Make

- CS - 444, LECO, USA

Specifications

- HF-400 induction furnace (18 MHz, 2,2 kW) for CO2/SO2 conversion

- Measured carbon in the range 0 to 0.5 %,

- Measures sulphur in the range 0 to 0.35 %

Details

Carbon/Sulphur system is a microprocessor based software driven instrument for wide range measurement of Carbon and Sulphur content of metals, ores, ceramics and other inorganic materials. It uses HF-400 induction furnace (18 MHz, 2,2 kW) for CO2/SO2 conversion. It works on the principle of infrared absorption of CO2 and SO2.

Confocal Micro-Raman Spectrometer with Mapping Facility

Make

Witec

Model

WITec UHTS 600

Specifications

- Laser Sources: 532 nm and 633 nm

- Raman spectral imaging: acquisition of a complete Raman spectra at every image pixel

- Planar (x-y-direction) and depth scans (z-direction) with manual sample positioning

- Image stacks: 3D confocal Raman imaging

Details

The Confocal Raman Microscope contains a compact and flexible platform optimized for high-end spectroscopy applications and confocal Raman imaging consisting of a research grade optical microscope with 6x objective turret, video CCD camera, LED white-light source for Köhler illumination, manual sample positioning in x- and y-direction and fibre coupling.

Centre

Centre for Nanomaterials

Cryo mill

Model and make :

1-s laboratory cryo mill; Union Process

Specifications:

- Tank capacity: 7 lt

- Max Ball to powder ratio: 32:1

Details:

Used for synthesizing nanostructured materials at cryogenic temperature of -190 C.

Advantages :

- Reduced oxide contamination

- Fine grain structures

- No sticking of powder to the container. < li>Fine particles.

Centre:

Centre for Nanomaterials

Digital Laboratory Hot Air Oven

Model & Make

UFE 700, Nabertherm GmbH, Germany

Specifications

- Memmert (UF160)

- Temperature range: 30-300 °C

- Dimensions: 560(w)*720(h)*400(d) mm

- Option: programmable temperature and duration

Details

Digital laboratory hot air oven is used for drying or curing of all sort of functional coatings / materials in a laboratory scale.

Centre

Centre for Nanomaterials

Electrochemical Analyzer

Model & Make

PARSTAT 4000 A, AMETEK

Specifications

- Maximum current output: ± 4A

- Maximum voltage output: ± 10V

- Frequency range: 10 µHz to 10 MHz

- Voltage sweep rate: 1mV/s to 25 kV/s

Details

The electrochemical analyzer with a wide current and potential window is used for electrochemical processing and characterization of samples and devices by various modes such as:

- Voltammetry – Linear scan voltammetry, cyclic voltammetry, staircase voltammetry, chronoamperometry, differential pulse voltammetry, etc.

- Corrosion – Linear polarization resistance (LPR), Potentiodynamic and potentiostatic, Galanodynamic and Galvanostatic corrosion, Tafel plot, etc.

- Impedance – Pontentiostatic and Galvanostatic EIS, Mott-Schottky analysis, etc.

- Energy – Charge-discharge analysis, Cycle stability, etc.

Centre

Centre for Nanomaterials

Electrolyte conductivity meter

Conductivity range: 1 μS per cm to 50 mS per cm

Resolution: 0.11 μS per cm

Accuracy: 0.5%

Resistance: 2 Ω to 100 MΩ

Accuracy 0.5 percentage of the value or better

Temperature: 0 to 100.0 degree C

Resolution: + 0.5 degree C

Accuracy: + 1 degree C

Details The electrolyte conductivity meter is capable of measuring conductivity, resistance and pH of any electrolytes. It can also measure the pH of any solvents.

Fatigue testing Machine

1.Servo Electric Low Cycle Fatigue machine

Make

ITW India Private Limited - BISS Division, Bengaluru, India

Model

AC-01-0010

Features

- As per ASTM 606

- Capacity: 100 kN

- Frequency: 0.01 to 2 Hz

- Modes: stroke, load and strain control modes

- Temperature: up to 1000 0C on M8, M10 and M12 samples

2. Servo Hydraulic High Cycle Fatigue machine

Make

ITW India Private Limited - BISS Division, Bengaluru, India

Model

AC-01-0010

Features

- As per ASTM E466

- Capacity: 100 kN

- Frequency: 1 to 100 Hz

- Modes: stroke, load and strain control modes

- Temperature: up to 1000 0C on M8, M10 and M12 samples

- Tensile test as per ASTM E8M

- FCGR test (da/dN) as per ASTM E 647

- J1c test as per ASTM E1820

- K1c test as per ASTM E399

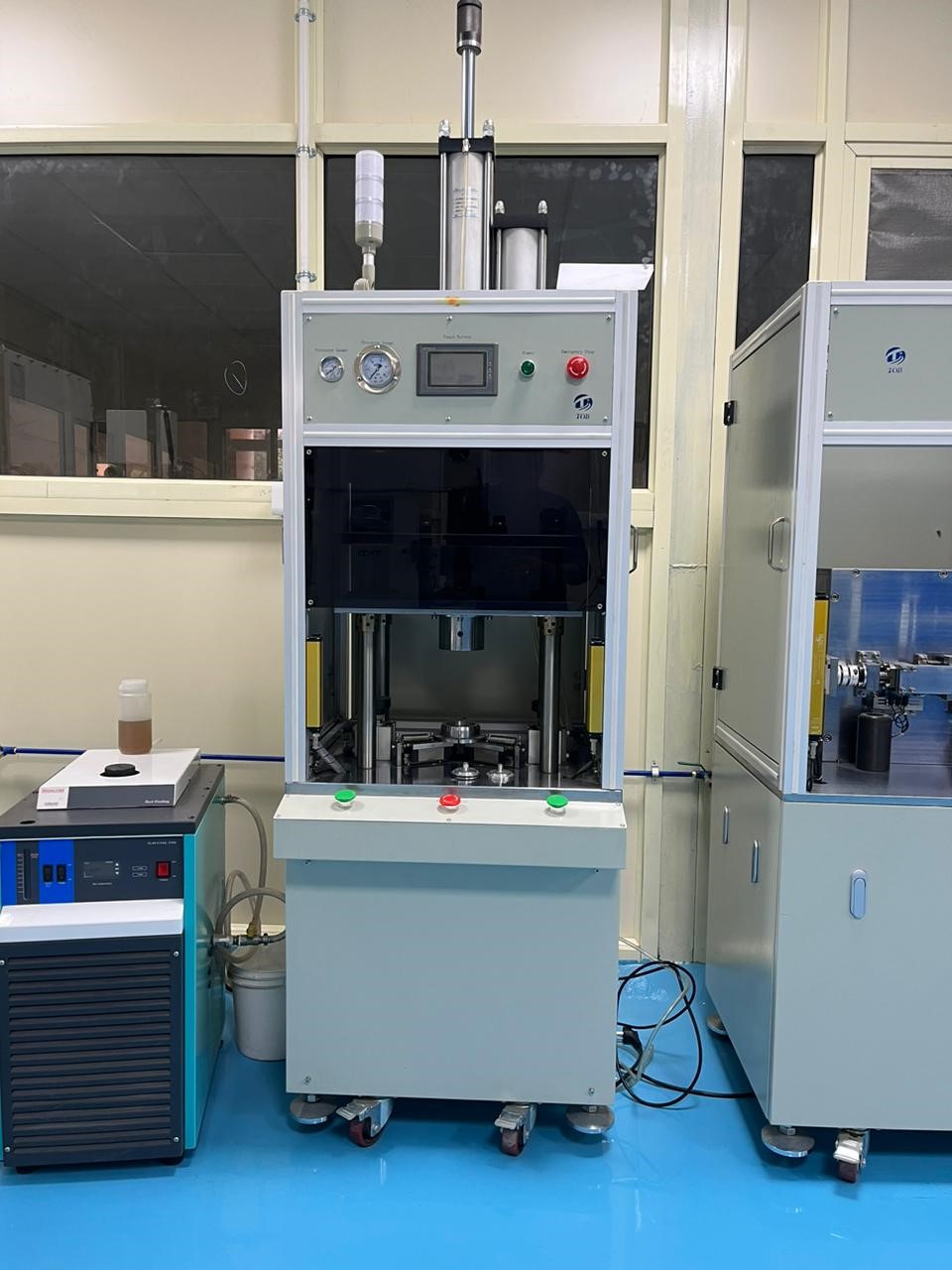

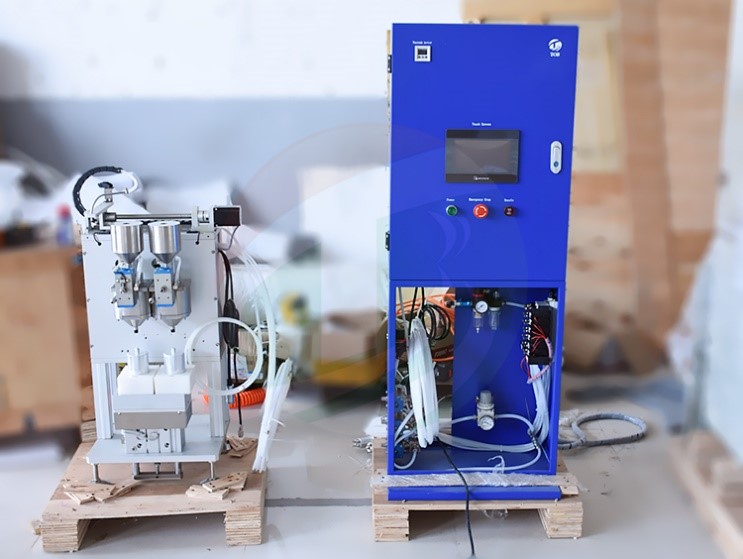

Feeding Machine

Model and Make

- TOB-RK60, China

Specifications

- The machine has provision for top and bottom cylinder to feed the cylindrical cell case at the bottom and the laser welded jelly roll with top cap and O-ring from the top.

- The machine operates with pneumatic control.

- Parameters: Suitable to feed cell cases with 60 mm diameter, Height: 50-150 mm.

- Capacity of feeding: 1 cell/minute

- Compressed air supply: 0.5 to 0.8 MPa

Details

The cell feeding machine is used to press the laser welded jelly roll with guide plates and top cap with O-ring into the 60mm dia. cylindrical cell case and to fasten the O-ring sealing inside the cell case.

Centre

Centre for Nanomaterials

Flame Spray Pyrolysis

Model No & Make

Custom made, Friedli AG, Switzerland

Details

Flame spray pyrolysis is the process where the formation of nanoparticles happen by conversion of liquid precursor in a flame and subsequent collision and sintering of reaction products in the high temperature environment. Liquid precursors that can be used in the flame spray process are metal nitrate solutions, metal salts of carboxylic acids or organometallic compounds to produce oxide, complex oxides and nobel metal supported oxides nanopowders.

The process has the following advantages:

- Broad range of product materials,

- Multi-component particles,

- High purity powders,

- Thermally stable powders,

- Environmentally friendly process,

- Short process chain,

- Standard equipment and materials

- Low cost energy source.

- Production rate ~1 kg/h

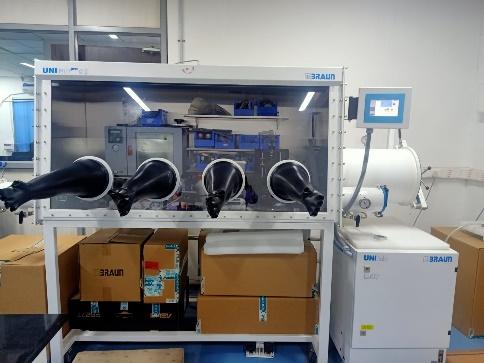

Four-port glove box with in-built vacuum oven facility

Model and Make

- UNIlabpro sp, MBraun

Specifications

- Four port

- Two manually operated small ante-chamber

- One PLC controlled large ante-chamber

- Environment: Argon

- Attached vacuum oven

- 20-25 L volume

- 30-200 degree centigrade temperature

Details

The UNIlabpro sp, MBRAUN four-port glove box attached with vacuum oven is an inert gas (Ar) filled gas station to handle the atmosphere sensitive materials, electrode and cell fabrication. The attached vacuum oven can be used to dry electrode materials and fabricated electrode film. The four port glove box has been designed for the electrode and cell fabrication in R&D level.

Furnaces

Tubular furnaces:

1.Model and make

Therelek, Model 2248-4 kW

Specifications

- Operate in Ar and N2 atmosphere upto 1000°C

- Press has a day light of 800 mm with a table size of 750 mm x 750 mm.

2.In-house

5 kW rating

Specifications

- Operate in Ar and N2 atmosphere upto 1000°C

- Chamber size: 90 mm dia x 300 mm

3.Model and Make

Krishna Enterprise

Specifications

- Operate in Ar and N2 upto 800°C

- Chamber size: 40 mm dia x 100 mm

4.Model and Make

Therelek, Thane

Specifications

- Operate in Ar and N2 atmosphere upto 1100°C

- Chamber size: 110 mm dia x 500 mm

Chamber furnaces:

1.Model and Make

Okay 70015-10 kW, Bysakh

Specifications

- Operate in air upto 1600°C

- Chamber size: 300 mm3

2.Model and Make

Technico make

Specifications

- Operate in air upto 1000°C

- Chamber size: 200 mm3

Reduction furnaces:

1.Model and Make

Termolab, Retort-15 kW

Specifications

- Operate in H2 and N2 upto 1200°C

- Chamber size: 200 mm dia x 300 mm

Center

Center for Nanomaterials

Glovebox (2 ports)

Model & Make

IL-2GB, Innovative Technologies, USA

Specifications

- Ports: 2 nos

- Gas: Argon

- Oxygen: <1 ppm

- Moisture: <1 ppm

- Transfer Chamber: 2

Details

Instrument used for storing and synthesis of materials under inert condition and coin cell fabrication.

Centre

Centre for Nanomaterials

Grooving Machine

Model and Make

- TOB-GCFK60, China

Specifications

- Grooving parameters: Suitable to groove with cell cases with 60 mm diameter, Height: 50-150 mm.

- Grooving height accuracy: ± 0.05 mm

- Grooving depth accuracy: ± 0.02 mm

- Capacity: Grooving minimum of 1 cell case/minute.

- Working conditions: 20-30°C, RH of 70-100%.

- The cylinder case will not rebound due to compression resistance, and provides uniform grooving.

Details

The grooving machine is used to groove cylindrical cell cases with the electrode jelly roll. It is essential for proper fitting of the jelly roll inside the cell case.

Centre

Centre for Nanomaterials

Helium gas Pycnometer

Make

POROTECH

Specifications

- Volume of the sample to be measured: up to 50 CC

Details

Centre

Centre for Nanomaterials

High vacuum high temperature Centorr furnace

Model and Make:

System VII, Centorr Vacuum Industries-USA

Specification:

Tungsten heating element and hearth; Hot zone size: 150mm x 150mm x 300mm; Maximum operating temperature: 2000 degree C; Operating

Atmosphere:

Vacuum (10^-6 Torr), Argon, Nitogen, Hydrogen (upto 1900 degree C); Quenching provision (forced gas quenching)

System details:

This multi-purpose furnace has wide range of options to carry out heat treatment, powder sintering and annealing under high (10^-6 torr) vacuum and up to 1-3 psig positive pressure of argon, nitrogen or hydrogen atmosphere. The system can be operated at high temperature up to 2000 degree C. The system is equipped with forced gas quenching setup for rapid cooling of the charge/sample(s) under inert gas within the furnace chamber after completion of the heat treatment. The system is fully automated with PLC control and has remote operation capability.

Center:

Center for Nanomaterials

High vacuum high temperature furnace

Model and Make

Hind Hi Vacuum Company Private Limited, Bengaluru, India

Specifications

- Molybdenum heating element and hearth; Hot zone size: 150 x 150 x 200 mm;

- Maximum operating temperature: 1200 degree C

Atmosphere

- Vacuum (10^-6 mbar), Argon and Nitrogen

System Details

This multi-purpose furnace has wide range of options to carry out heat treatment, powder sintering and annealing under high (10^-6 torr) vacuum and up to 1-3 psig positive pressure of argon and nitrogen atmospheres. The system can be operated at high temperature up to 1200 degree C.

Centre

Centre for Nanomaterials

Hot powder extrusion facility

Model & Make

- In-house developed facility

Specifications

- Maximum load: 1150 MPa

- Billet size; 50 mm

- Extrusion ratios: 4 to 30

- Maximum temperature: 1150°C

Details

- Alloy powders are extruded into various-sized solid rods depending on the materials.

Hydrogen Absorption/Desorption Kinetics Measurement Facility

Model & Make

Custom-made

Specifications

Kinetics can be studied in the temperature range of 30-350oC and pressure range of 0.01-70 bar

Details

The absorption/ desorption kinetics can be evaluated by monitoring the variation of pressure with time. The pressure sensors and thermocouples are connected to data logger and the data in continuously recorded during the measurement. This facility gives the hydrogen absorption/desorption kinetics in case of the materials being tested at given temperature and pressure.

Centre

Centre for Nanomaterials

Inert Gas Atomizer

Model & Make

HERMIGA 100/10 VI, PSI, UK

Specifications

- Capacity (per batch): Typically 4kg of aluminium alloys, 10kg of iron, nickel and copper dependent on charge form.

- Temperature: 175oC

Details

The equipment is used to make spherical powders using inert gas atomization process in which the oxygen content is minimum (<100 ppm). Various metal/alloy powders based on aluminium, iron, silver, zinc, nickel, gold, magnesium, copper, palladium, beryllium, cobalt, tin, lead and others can be made using this equipment.

Centre

Centre for Nanomaterials

Jelly Roll Core Flattening Machine

Model and Make

- India

Specifications

- Provided with cutting, curling and flattening function.

- The machine operates with pneumatic control.

- Operates with pneumatic supply.

- Operate jelly rolls with a min dia. of 56-58 mm

- Operates jelly rolls length ranging from 60-150 mm with weight approx. 130 g.

Details

The flattening machine used for flattening both ends of jelly roll simultaneously with three operations in series using 3 different tools. The jelly roll made by winding aluminium foils of 20 micron thick coated with 100-micron carbon on each side of foil. The flattening of jelly roll on both sides is required for laser welding of guide plates to either side of jelly roll.

Centre

Centre for Nanomaterials

Micro Focus X-Ray Diffractometer

Model and Make

- RAPID-II-D/MAX MICROFOCUS X-ray Diffraction System (RIGAKU Corp., Japan)

Specifications

- Rigaku-MICROMAX 007 HF rotating anode (Cu and Cr target)

- 2D-curved image plate detector (size: 470 x 256mm)

- collimators: 10, 30, 50, 100, 300 and 800 mm diameter

- 2theta range: -47 to +163 degree

Details

This is the most versatile laboratory scale x-ray diffraction system. It is equipped with high intensity microfocus rotating anode x-ray source-Rigaku MicroMax 007HF, which has brightness close to a second generation synchrotron with x-ray flux of 1014 to 1015 x-ray photon/mm2/s at the focal point. The system also has a highly sensitive and large image plate based 2-dimensional (2D) detector, which ensures a full scan from -47 to +163 degree for 2theta in a single exposure of very small duration. It has both Cu and Cr target option with provision to bring the beam spot size down to 10 micron. The system can be operated in reflection, transmission and glancing incidence configuration. It can perform wide range of studies like phase analysis, texture, residual stress, trace phase detection (for phase fraction of 0.1% or less) in micro/macro-area apart from thin film analysis in the glancing incidence mode. In addition, it has a provision to perform fully automated area mapping using auto stage.

Microwave Plasma Synthesis

Model & Make

Custom-made

Specifications

Ceramics such as carbides, nitrides, oxides and solid solutions with size ranging from 50-90 nm and with surface area in the range of 10-45 m2/g can be synthesized by the process

Details

In microwave plasma synthesis, the microwave produced by a magnetron are wave-guided to generate a plasma. The desired precursor is injected into the plasma, and decomposition of the precursor occurs to produce nanopowders. The particle size, morphology and phase formation can be controlled by changing process parameter like plasma forming gas, precursor, feed rate, carrier gas flow rate, additional gas flow rate and power of the magnetron. The precursor can be in solid, liquid or in gaseous form.

Centre

Centre for Nanomaterials

Multi Piston Hot Press

Model & Make

Redson make

Specifications

- No of pressure pistons : 3

- Capacity of each piston, T: 3 max.

- Number of stacks: 3

- Maximum diameter of the component, mm: 90

- Charge height with holding fixture, mm: 250

- Maximum Temperature, C : 1050

- muffle pressure, mbar : 500

- Charge stacking and loading arrangement: Semi-automatic

- Sintering atmosphere : Hydrogen, nitrogen

Details

The advantage of the above hot press is that it works on both laboratory scale as well as pilot level. The split hood deign of the muffle enables faster cooling and batch completion time. The pistons being independently operating allows different pressure conditions to be set simultaneously, facilitating less no. of cycles for different experimental conditions. The furnace has been designed such that power consumption is very minimal and can be operated with either 100 % hydrogen, or nitrogen flowing gases unlike conventional hot presses which are designed for either inert or vacuum. Thus metallic, cerametallic or even polymer based samples can be processed.

Centre

Centre for Nanomaterials

Multi-channel Battery tester

Model and Make

- LBT20184UC, Arbin Instruments

Specifications

- Serial No: 211223

- Channels: 32 Nos.

- Max Current: ~5 A

- Min Current: ~100 µA

- Voltage Range: 0 V - 10 V

Details

Arbin Instruments LBT20184UC is a multi-channel battery cycler, having total 32 channels for the testing of coin/Swagelok/pouch type cells of low to moderate capacity. The battery cycler has been designed for the testing of cells fabricated in R&D level. Each channel in this system is capable of testing the cells independently, enabling users to run tests on multiple cells at the same time. The features of Arbin Instruments LBT20184UC are: (i) completely independent channels allow users to run multiple independent tests simultaneously without affecting the other channels, (ii) accuracy up to 0.02% for low power and 0.05% for high power applications, (iii) Potentiostatic/Galvanostatic stations fine-tuned for battery Research & Development, and (iv) Up to three current ranges per station available for improved accuracy over a wide range of testing conditions.

Nano Spider

Model and Make

- NS lab 500 S, Elmarco

Specifications

- Maximum width: 500 mm

- Maximum speed : 500 mm/ minute

- Maximum Voltage: 70 KV

Details

Electrospinning is a spinning method that uses electrostatic forces to produce nano-sized diameter fibres from polymer solutions. In comparison to conventional spinning techniques, electrospun fibres have a narrower diameter (from nanometer to micrometre) and a larger surface area. The nano additives can be incorporated into the fibers during the electrospinning. The solution is fed into the device with the aid of spinning electrodes (nozzle less or syringe less). Type of polymer fibre that can be electrospun depends on flash point of the solvent used in the solution.

Oxygen-Nitrogen Analyzer

Model and Make

ON - 900, Eltra, Germany

Specifications

- Oxygen is detected as CO2 in IR-cell

- Nitrogen is detected by a thermal-conductivity-cell

- Measured oxygen in the range 0 to 0.5 %,

- Measures nitrogen in the range 0 to 0.5 %

Details

Oxygen/Nitrogen system is a microprocessor based software driven instrument for wide range measurement of oxygen and nitrogen content of metals, ores, ceramics and other inorganic materials. It uses induction furnace for CO2/SO2 conversion. It works on the principle of infrared absorption of CO2 and SO2.

Centre

Centre for Nanomaterials

Planetary Vacuum Mixer

Model and Make

- STC-EXJ5L, China

Specifications

- Capacity:5 L, diameter 200-220 mm and depth of 170-200 mm.

- Cooling Jacket: Water

- Mixing blade speed: Min. 80 rpm or more

- Dispersion rotation speed: Min.3500 rpm

- Scrape wall speed: Min.80 rpm with Teflon wall.

- Electric lifting of the base provided with lifting stroke of 280-300 mm.

- Vacuum hold:-0.099 to -0.001Mpa

Details

The planetary vacuum mixer machine is used at lab scale for research and development to prepare homogeneous and bubble free viscous slurries for the fabrication of electrode foils in lithium-ion battery and supercapacitor manufacturing process

Centre

Centre for Nanomaterials

Planetary vacuum mixer

Model and Make

- Dual shaft planetary mixer, Gelon LIB Co Ltd. China.

Specifications

- Rotary Speed: 0-800 rpm

- Mixing Container: 150 ml, 500 ml

- Mixing blades: Biaxial planetary stirring

Details

The slurry for lithium-ion battery/supercapacitor electrode coating is prepared by mixing active electrode material, conductive carbon black and a polymer binder in a planetary vacuum mixer to achieve viscous homogenous slurry.

Planetary vacuum mixer machine

Model and Make

- Dual shaft planetary mixer, Gelon LIB Co Ltd. China.

Specifications

- Rotary Speed: 0-800 rpm

- Mixing Container: 150 ml, 500 ml

- Mixing blades: Biaxial planetary stirring

Details

The slurry for lithium-ion battery/supercapacitor electrode coating is prepared by mixing Active electrode material, conductive carbon black and a polymer binder in a planetary vacuum mixer to achieve viscous homogenous slurry.

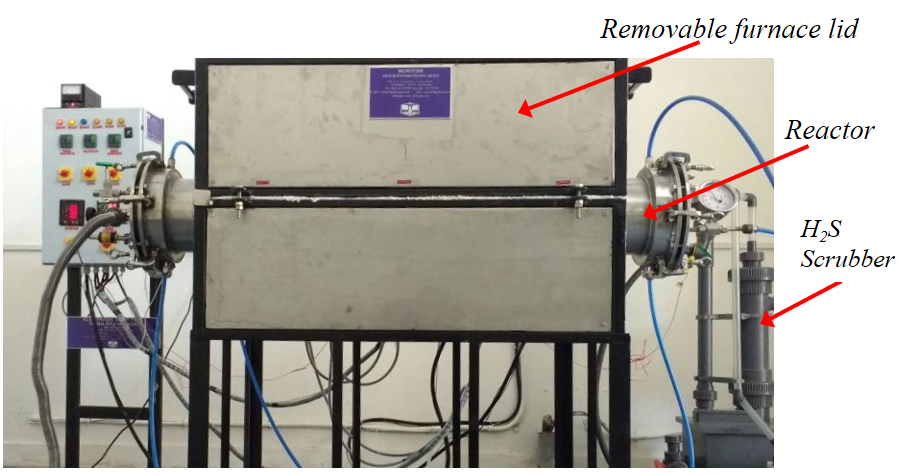

Pressure Synthesis Reactor

Model and Make

- Custom designed and fabricated

Details

Reactor can be operated under vacuum (10-3 torr) as well as under positive pressure of up to 10 bar of argon, nitrogen, hydrogen and hydrogen disulphide at a maximum temperature of 1000-degree C. The reactor can be used for elevated temperature processing (synthesis/deposition) of corrosive materials or under corrosive environment. The reactor has the provision for fast cooling as well as fast scrubbing of the effluent gases.

Pulse Power Supply

Model & Make

DPR series (DuPR 10-3-6); Dynatronix INC, USA

Specifications

- Real Time Cycle Control

- Ampere Time Cycle Control

- Ampere Time Totalizer

- Error signals for over-temperature, locked fan rotor, output out-of-tolerance and power failure/brownout conditions

- Calibration capability through the control interface

- Straight DC or High Frequency Pulse Output (0-5000 Hz) Capability

- 0 - 10.0 volts average (DC) or peak (pulsed) voltage

- 0 - 3.0 amps average current (or maximum DC current)

- 0.3 - 6.0 amps peak (pulsed) current

Details

Fully-programmable power supply for DC, Pulse and Pulse Reverse electrodeposition and Electrochemical anodization

Centre

Centre for Nanomaterials

RF Induction Plasma

Model & Make

60 kW; Tekna Plasma Systems, Canada

Specifications

- Power rating: 60 kW

- Electrode less process

- Precursor: Solid, liquid and gases

- Atmosphere: Oxidizing, reducing or inert as per requirement

- Plasmas generated through electromagnetic coupling of electrical energy in the discharge cavity

- Production rate: 0.5-1 kg/hour

Details

Nanopowders of pure metals (Al, Ni, Ti, Cu, Ag, W), oxides (Al2O3, ZrO2, TiO2, SiO2), carbides (SiC, B4C, TiC, WC) and nitrides (TiN, Si3N4, BN) etc can be produced in bulk quantities (several kilograms per hour).

Centre

Centre for Nanomaterials

Roll-to-Roll Coating Machine

Model and Make

- TOB-SY300J, China

Specifications

- Method: Comma coating method, the machine should be capable of single face continuous and intermittent coating

- Coating line speed: Adjustable upto 2 m/min

- Dryer temperature: RT-150 oC

- Drying method: Hot air circulation with upper and lower double-sided blowing for electrode drying.

- Maximum coating width: 260 mm

- Maximum coating thickness: 400 micron

Details

The roll-to-roll coating machine will be used for coating viscous slurry to make homogenous thickness electrode foils for cell fabrication.

Centre

Centre for Nanomaterials

Sealing Machine

Model and Make

- TOB-MFK60, China

Specifications

- Sealing parameters: Suitable to seal with cell cases with 60 mm diameter, Height:50-150 mm.

- Capacitor height accuracy after sealing: ±0.05 mm.

- Sealing shell accuracy after sealing: ±0.03 mm

- Capacity: Sealing minimum of 1 cell case/minute

- The sealing result in airtight sealing of the case to prevent electrolyte leakage.

- It provides with a booster cylinder control mould for parallel sealing of the upper and lower moulds to easily form an automation.

Details

The sealing machine is used to seal cylindrical cell cases after grooving with the electrode jelly roll. It is essential for proper sealing of the cell for final testing and usage.

Centre

Centre for Nanomaterials

Semi-Automatic Winding Machine

Model and Make

- TOB-15060YZ, China

Specifications

- Winding unit: cylindrical type

- Needle or Mandrel diameter: 6 mm-60 mm.

- Needle length: 80 mm.

- Automatic winding, automatic needle change, automatic separator cut off, stick termination of tape and blanking is provided.

- Line tension (variable): 0.1 N to 0.7 MPa

- Production rate: 1-2 jelly roles /minute

- Control system: PLC and HMI, servo and stepper motor

Details

This machine will be used for making electrode jelly rolls for making cylindrical type Supercapacitor cells

Centre

Centre for Nanomaterials

Slitting machine

Model and Make

- TOB FT500, Xiamen TOB New Energy Technology Co Ltd. China.

Specifications

- Slitting width: 20-500 mm

- Slitting mode: single knife hobbing

- Slitting thickness: max. 300 microns

Details

The dried and calendared electrode foils are slit into desired width and length based on the cell dimensions to make jelly rolls for lithium-ion battery/supercapacitor cell fabrication.

Spark Plasma Sintering

Model & Make

SCM 1050, Sumitomo Coal Mining Co, Ltd Japan

Specifications

- Current: upto 5 kA

- Voltage: upto 10V

- Load: 100 kN

- Campact size: 30 mm dia max.

- Vacuum level: upto 6 Pa

- Molds: graphite

Details

The spark plasma sintering (SPS) process is the most advanced form of sintering where it is possible to retain submicron structures at low sintering temperatures and short times. The difference between SPS and other sintering methods has ramifications in process efficiency and energy savings as well as microstructural and compositional implications. These beneficial effects have been largely attributed to a) the higher heating rates, b) imposition of an electric field and c) applied stress during sintering.

Centre

Centre for Nanomaterials

Supercapacitor Testing Station

Model No & Make :

PARSTAT 2000 & Advanced Measurement Technology INC, USA

Key Features

Advanced Measurement Technology INC, is a multi-channel testing system designed for R& D and production of supercapacitors, batteries and other electrochemical energy storage devices. Each channel operates independently of each other enabling users to run tests on multiple devices at the same time.

The features of Advanced Measurement Technology INC, are (i) completely independent channels allow users to run multiple independent tests simultaneously without affecting the other channels, (ii) accuracy up to 0.02% for low power and 0.05% for high power applications, (iii) Potentiostatic/Galvanostatic stations fine-tuned for battery Research & Development, and (iv) High capacity current boosters (20A) are available to test the commercial supercapcitor devices.

Specifications

- Serial No: PMC CHS08A

- Dimensions (W xL xH, inch): 14 x30 x25

- Channels: 24 Nos.

- Current range: -2 A ~ 5nA

- Voltage Range: 0 V ~ 10 V

- Frequency range: 10 µHz- 7 MHz

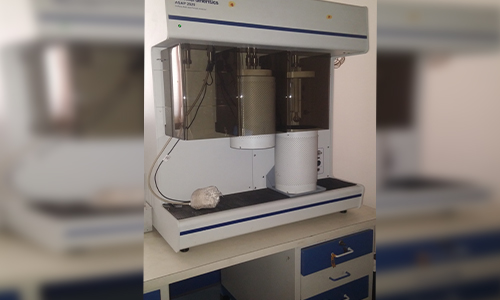

Surface Area and Porosity Analyzer

Model & Make

ASAP 2020

Details

Surface area and porosity are two important physical properties of the nanopowders that can be measured by this method. The equipment works on gas absorption principle therefore, it is very effective tool to study the surface morphology of the materials. Surface area (as low as 0.05m2/g) can be measured. It can measure adsorption and desorption isotherms to determine the shape of pores. It is possible to carryout measurements using adsorbates such as N2, Ar, CO2 and Kr selectively and also capable of measuring Langmuir surface area and pore size distribution. Volume, area, total pore volume and pore size in the range 0.35 to 500nm can be determined.

Centre

Centre for Nanomaterials

Swagelok Cell

Model and Make

- Panama, India

Specifications

- Used for battery material testing like as coin cells

- The machine operates with pneumatic control.

- Testing will be carried out in Swagelok cell with variable diameters like 12 mm, 14 mm, 15 mm and 16 mm etc maintaining a good contact of all parts like as coin cells.

- Reusable after cleaning unlike coin cells.

Details

It is used to carry out electrochemical studies of electrodes like cathodes (NMC, LFP etc.) and anode (Graphite, LTO etc) material in half cell and full cell level.

Centre

Centre for Nanomaterials

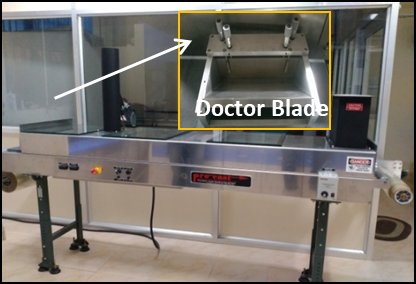

Tape caster

Model & Make

- HED International, Model No: TC-71LC

Specifications

- Overall Length : 9.66’ ( 2.95 meters ) nominal

- Casting Length : 7’ ( 2.13 meters) nominal

- Casting Width : Up to 12” ( 300 mm ) wide

- Casting Speed Range : 2 and 20 inches/minute ( ipm)

Casting Surface:

A granite surface plate 12” x 18” x 3” with a +/- 0.0005” tolerance precision ground casting surface.

Caster Construction:

Aluminum. The chamber is equipped with tempered glass view ports that are removable for product access.

Conveyor / Carrier:

Mylar or Paper.

Carrier Conveyor Drive:

A variable speed drive, located at the discharge end of the tape caster conveyor drive, is provided complete with an operator interface mounted on the caster structure.

Control Console :

Control instrumentation, switches, function labels, status lights, relays and fuses are located in the caster structure.

Doctor Blade:

An adjustable, single doctor blade fixture with a micrometer adjustable lift of 0” to 0…250” ( 0 to 6 mm )

About

The tape casting is used for the processing of ceramics, ceramic composites to make thick films for various applications such as capacitors, resistors, multilayer varistors, inductors. The green tapes are prepared by casting aqueous or organic solvent-based slip (powdered raw material suspended in a liquid) containing the ceramic powders, solvents, binders, plasticizers, surfactants, dispersants etc. to form the thick films/ tapes. It is very useful for versatile research and development activities.

Three-Dimensional (3D) Mixer

Make

- Hexagon Product Development Private Limited, Vadodara, Gujarat.

Model

- ALPHIE-10

Specifications

- Power Supply: 0.5 HP, 220 V

- Gross volume capacity: 10 Litre

- Cage Speed: 10 to 70 rpm adjustable

- Clamping device: Nonmetallic crown with rubber strings

- Speed and time change facility, forward reverse cycle speed provision

- Plug, program and operate hassle-free.

Use

- To thoroughly mix metal, ceramic and alloy powders.

- Inert atmosphere may be used in the cans if required.

Ultrasonic welding machine

Model and Make

- TOB USW 2600W, Xiamen TOB New Energy Technology Co Ltd. China.

Specifications

- Frequency: 24 KHZ

- Max. output power: 2600W

- Welding heads for Al and Cu

Details

The ultrasonic welding machine is used to weld single layer/multi-layer electrode stacks together along with terminal Al/Ni tab connections in pouch type/cylindrical lithium-ion battery cell fabrication.

UV-Visible Spectrophotometer

Model & Make

Perkin Elmer Lamda 650 UV/VIS spectrophotometer

Specifications

- Wavelength range: 175 to 900 nm

- Lamps: deuterium lamp and tungsten iodine lamp

- Fully PC controlled equipment

- Scanning speeds: 10-300 nm/min

Details:

UV visible spectroscopy enables the characterization of functional groups in a molecule as well as the determination of their concentration. It is widely applied in environment analysis, purity assessment and investigation of chemical reactions. The equipment is capable of measuring both solid (i.e. nano silver, TiO2, ZnO) and liquid samples (i.e nanopowder suspension)

Centre

Centre for Nanomaterials

Vaccum Filling Machine:

Model and Make

- TOB-ZY60B, China

Specifications

- Parameters: Suitable to seal with cell cases with 60 mm diameter, Height: 50-150 mm.

- Provides two filling stations to fill 2 cells at a time.

- Electrolyte filling capacity: 20 ml-250 ml with automatic injection mechanism.

- Vacuum during electrolyte Injection: 10-3 to 10-4 Kpa.

- The machine is pneumatically controlled.

- The machine is able to work in temperature of 20-30 °C inside a glove box under inert atmosphere.

- The size of electrolyte filling machine provided with a dimension of 1200 mm length, 780 mm depth and 920 mm height inside the glove box.

Details

The vacuum filling machine is used to inject electrolyte into the cylindrical cell cases after sealing and should be operated inside a glove box or in a dry room with less than 1 percentage relative humidity.

Centre

Centre for Nanomaterials

Vacuum Induction Melting (VIM) Furnace

Make

Jointly developed by ARCI and Inductotherm India Pvt. Ltd

Features

- Melting capacity: 2-10 kg

- Temperature capability: ~1850 °C

- Working atmosphere: Vacuum (10-4 mbar)/ inert gas

- Casting mould with heating facility (500 °C)

- Alloy addition facility with controlled atmosphere

X-Ray Photoelectron Spectroscopy (XPS)

Model & Make

Omicron Nano Technology, UK

Details

The instrument has the capabilities of depth profiling by Ar ion etching, Imaging XPS, Auger photoelectron spectroscopy (static and scanning modes), Scanning Electron Microscopy (SEM), Sample heating (upto 100oC) and cooling (liq N2 temp.). The technique being surface sensitive, it is very useful to characterize nanomaterials including, powders and thin films.

Centre

Centre for Nanomaterials

ZOZ High Energy Milling Machine

Model & Make

Simolayer CM-08, Zoz GmbH, Germany

Specifications

Production capacity: 1 kg of nanostructured powders per batch

Details

A high energy horizontal ball mill, Simolayer CM-08, is set up on a joint project between ARCI and Zoz GmbH, Germany, for the production of nanostructured and high performance materials.. The materials being produced include nanostructured zinc flakes for anti-corrosion paints, nanostructured Zn-Al flakes for cold gas dynamic spraying applications, nanostructured Ag flakes for additives in soldering paste, oxide dispersion strengthened materials, hydrogen storage materials, etc.

Centre

Centre for Nanomaterials

Zoz Simolyer Mill

Model & Make

CM-20, Zoz GmbH, Germany

Specifications

Capacity (per batch): 4 kg

Details

The equipment is used to carry out high energy milling of powders. As the mill imparts high kinetic energy to the powder through balls, the process takes short time there by eliminating contamination of the material being processed. The mill is used to produce nano-structured materials, non-equilibrium compositions and dispersion of oxides and carbon nano tubes in metals/alloys.

Centre

Centre for Nanomaterials