Centre for Automotive Energy Materials (CAEM)

In-situ carbon coating technique for layered oxide cathode materials for Lithium ion battery

Overview

Uniform carbon coating on electrode materials for lithium ion battereis is an effective method to increase the cyclic stability of lithium ion cells. By a novel in situ technique of solid state reaction of carbon precursor pillared metal hydroxides having uniform carbon coating on oxide electrodes such as LiNi1-x-yCoxMnyO2, LiMn2-xN1-xO4, LiNi1-x-yCoxAlyO2, NaNi1-x-yCoxMnyO2, Li2MnO3: LiNi1-x-yCoxMnyO2 has been achieved. A improved cyclic stability of the uniform carbon coated cathode materials compared to that of bare materials for lithium ion battereis is demonstrated

Key Features

- Air ambient synthesis

- Insitu single step uniform carbon caoting

- Scalable manufacturing process

- Easily extendable to all oxide active material for Li/Na ion battereis

Potential Applications

- Lithium ion battereis

- Sodium ion batteries

Intellectual Property Development Indices (IPDI)

- Performance and stability are validated at laboratory scale

- Scale-up synthesis is underway

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- A process for in-situ carbon coating on alkali transition metal oxide, M. B. Sahana, S. Vasu, M. Sathiya, and R. Gopalan, Patent Application No. 201611007461, Date of filing: March 03, 2016.

- In-situ carbon encapsulation of LiNi1/3Co1/3Mn1/3O2 using pillared ethylene glycol trapped in the metal hydroxide interlayers for enhanced cyclic stability S Vasu, M. B Sahana, C Sudakar, R Gopalan, G Sundararajan Electrochimica Acta 251, 363-377

Ozone-friendly magnetic refrigerators – an alternative to conventional cooling technology for energy saving

Overview

Air conditioners and refrigeration make a major contribution to the global energy consumption. Conventional refrigerators work on energy-guzzling vapor-compression technique and they produce hydrofluorocarbons that are greenhouse gases that contribute to global climate change when they escape into the atmosphere. Thus, there is a strong thrust to develop an energy-efficient technology. Magnetic refrigeration is an environmentally friendly technology that uses magnetic fields to change a magnetic material’s temperature (i.e. the magnetocaloric effect - MCE) and allows the solid material to serve as a refrigerant. This technology is energy efficient, eco-friendly and produces low vibration and noise. Thus, the need of the hour is to find suitable magnetocaloric materials that are cost-effective and exhibit large MCE spanning over a wide temperature range from low to room temperatures. Our research aims to develop magnetocaloric materials for active magnetic refrigeration applications.

Key Features

- Developing advanced materials with magnetocaloric effect for energy efficient refrigeration.

- Rare-earth free, economic Ni-Mn based Heusler alloys, Mn- based alloys, exhibiting first-order transition are being explored for magnetic refrigeration

- A huge inverse magnetic entropy of 17 J/kg-K in Ni-Mn based Heusler alloys and 19 J/kg-K in Mn-Fe-P-Si alloy (normal magnetic entropy) are obtained near ambient temperature at 3 T magnetic field

Potential Applications

- Household refrigerators

- Air-conditioning (Halls, automobiles etc.)

- Food preservation

Intellectual Property Development Indices (IPDI)

- Synthesized single phase and prudent Ni-Mn based and Mn based magnetocaloric materials, which exhibits magnetocaloric effect at ambient temperatures.

- Upscaling of the magnetocaloric materials is underway

- Development of prototype to demonstrate magnetic refrigeration is under progress.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- S.Kavita, V.V.Ramakrishna, Poonam Yadav, Sravani Kethavath, N.P.Lalla, Tiju Thomas and R.Gopalan, J.Alloys and Comp., 795,519 (2019)

High voltage carbon encapsulated-graded LiMn2O4:LiNi1-x-yCoxAlyO2 cathodes for rechargeable Li-ion pouch cells

Overview

Layered-structures such as LiNi1-x-yMnxCoyO2 and LiNi1-x-yCoxAlyO2 are currently used as cathode materials in LIB for high-energy applications. However, practical achievable capacity of these materials are restricted to 150-200 mAh/g due to the limitation in the achievable charging voltage (4.2 V) with acceptable cyclic stability. If over-charge (above 4.2 V) induced surface degradation in LiNi1-x-yCoxAlyO2 can be prevented, it is possible to achieve high reversible capacity up to 230 to 250 mAh/g. The minimization of surface induced degradation is observed in surface modified LiNi1-x-yCoxAlyO2 (LNCA)

Key Features

- Scalable synthesis method

- Higher specific capacity

Potential Applications

- Lithium ion batteries

Funding Agency : DST

Intellectual Property Development Indices (IPDI)

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Concentration Gradient-Driven Aluminum Diffusion in a Single-Step Coprecipitation of a Compositionally Graded Precursor for LiNi0.8Co0.135Al0.065O2 with Mitigated Irreversibility of H2 ↔ H3 Phase Transition, Sasikala Natarajan, Sahana B. Moodakare, Prathap Haridoss and Raghavan Gopalan, ACS Appl. Mater. Interfaces 2020, 12, 31, 34959–34970

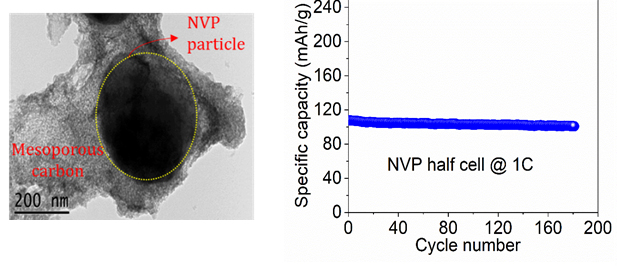

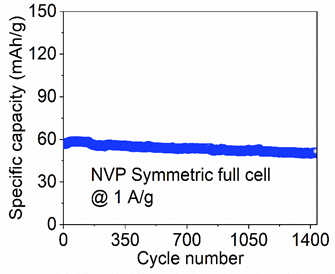

Low-cost Sodium ion batteries for energy storage applications

Overview

Sodium ion batteries (SIBs) are considered as potential alternative to Lithium ion batteries (LIBs) for large scale energy storage applications, such as grid energy storage and electric vehicle (EV) applications due to abundance of sodium, high specific energy and low-cost. However, plenty of research efforts are required to find suitable electrodes and electrolytes to achieve specific energy similar to that of LIBs. Hence, different electrode materials are selected based on their promising electrochemical performances. Polyanionic compounds with long cycle life and layered sodium transition metal oxides with high specific capacity as cathodes; whereas hard carbon and sodium titanates with low sodium insertion potential and high specific capacity as anodes have been prepared using novel chemical approaches and their electrochemical performances have been investigated using indigenously developed non-aqueous based electrolyte. Full cells (Pouch-type) have been fabricated using polyanionic compound (here, sodium vanadium phosphate) as cathode and hard carbon as anode and the electrochemical studies are under progress.

Key Features

- High specific energy and power density, good rate capability, excellent cycle life, high thermal stability and safe-in operation.

- Low- cost and wider operating temperature range.

Potential Applications

- Large scale electric energy storage (EES)

- Stationary energy storage

- Electric/hybrid electric vehicles

Intellectual Property Development Indices (IPDI)

- Electrolytes with high ionic conductivity (>10-3 S/cm) and electrochemical stability window (>4.2 V) has been prepared and tested.

- Electrode materials with excellent sodium ion storage performance has been developed, where cycle life >1000 cycles has been demonstrated in full cell configuration.

- Optimization of large scale synthesis (500 g/batch) and pouch cell fabrication (1 Ah) are under progress.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- Microwave assisted sol-gel process for preparing in-situ carbon coated electrode materials and the product there of,” (2019) Bijoy Kumar Das, P. Laxman Manikanta, N. Lakshmipriya, R. Gopalan, G. Sundararajan, Indian Patent 201911008004.

- Microwave assisted sol-gel process for preparing in-situ carbon coated electrode materials and the product thereof”, (2020) Bijoy Kumar Das, P. Laxman Manikanta, N. Lakshmipriya, R. Gopalan, G. Sundararajan, European Patent: 20763813.1

- Microwave assisted sol-gel process for preparing in-situ carbon coated electrode materials and the product thereof”, (2020) Bijoy Kumar Das, P. Laxman Manikanta, N. Lakshmipriya, R. Gopalan, G. Sundararajan, Japanese Patent: 2020-550159

- Microwave assisted sol-gel process for preparing in-situ carbon coated electrode materials and the product thereof”, (2020) Bijoy Kumar Das, P. Laxman Manikanta, N. Lakshmipriya, R. Gopalan, G. Sundararajan, Korean Patent: 10-2020-7025994

Major Publications

- Scalable synthesis and kinetic studies of carbon coated sodium titanate: A promising ultra-low intercalation voltage anode for sodium ion battery”, P. Laxman Mani Kanta, M. Venktesh, Satyesh Kumar Yadav, Bijoy Kumar Das*, R. Gopalan, Trans. Ind. Nation. Acad. Eng. 5 (2020) 475-483.

Book Chapter

- Bijoy Kumar Das, R. Gopalan (2019) 'Intercalation-based Layered Materials for Rechargeable Sodium-ion Batteries', Layered Materials for Energy Storage and Conversion. RSC Publisher.

Development of Lithium-ion Batteries for Electric Vehicle Application

Overview

Due to the depletion of the fossil energy reserves as well as alarming level of greenhouse gas emission triggered to look out for alternative clean energy sources, especially for automotive sector. The key challenge for electric vehicles is to get suitable battery to store the required amount of energy in a given volume for long driving range and speed. Lithium-ion battery (LIB) has been proven to be next generation technology to alleviate these problems. However, currently there are no manufacturers of these batteries in India. ARCI has undertaken a major task to developed LIB technology for electric vehicles by setting up a pilot plant facility for manufacturing of Lithium-ion cells and battery packs for automotive application. The objective is to establish the LIB technology using standard materials and demonstrate off-line/on-board vehicle testing. In addition high voltage/new materials will be developed indigenously. The promising materials will be optimized and scale-up for process technology.

Key Features

- ARCI has successfully fabricated prismatic/cylindrical cells (up to 20 Ah) and LIB module up to 48V, 1 kWh

- A fast cell formation protocol (6h) was developed and patented which is anticipated to reduce the cell production cost

- On-road test trails have been conducted with e-cycle (~30 km/charge) and e-scooter (~52 km/charge) using the LIB modules

- ARCI is developing several cathodes, anodes, and binder materials that could increase the performance and lifetime of LIBs for EVs. The cathode materials include LFP, NMC, NCA, LMO, LNMO, FeF3 whereas high energy/power density anodes include Si, Sn, MoO3, WO3, SnO2, Fe3O4, graphene, carbon nanohorns/nanotubes.

- Development of aqueous binders such as PVA, SA, CCD, guar gum for green and cost-efficient electrode production is underway

- Scaled up LiFePO4 by FSP process and scale-up of carbon coating technology up to 1.5 kg

- Lithium titanate was successfully synthesized and up-scaled by cost-effective high energy milling method and showed promising electrochemical performance in terms of capacity, rate capability and cyclic stability in comparison with commercial LTO.

- ARCI has signed several NDA and MOUs with potential cell manufacturers, automotive and raw materials manufacturing industries to produce Made-in-India LIBs.

Potential Applications

- Two, three and four wheeler electric vehicles

- Stationary energy storage applications

- UPS

Intellectual Property Development Indices (IPDI)

- Cells have been fabricated and electrochemical performance has been tested

- Assembly and testing of large format battery module/pack carried out with e-cycle and e-scooter under on-road conditions.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- S.R. Sahu, V.R. Rikka, P. Haridoss, A. Chatterjee, R. Gopalan and R. Prakash, " A Novel α-MoO3/Single-Walled Carbon Nanohorns Composite as High-Performance Anode Material for Fast-Charging Lithium-Ion Battery", Advanced Energy Materials, Vol 10, p 2001627, 2020

- S. R. Sahu, V.R. Rikka, P. Haridoss, R. Gopalan and R. Prakash, “Superior cycling and rate performance of micron-sized tin using aqueous-based binder as a sustainable anode for lithium-ion batteries”, Energy Technology, Vol. 7(11), Article No. 1900849, 2019

- V.R. Rikka, S.R. Sahu, A. Roy, S.N. Jana, D. Sivaprahasam, R.Prakash, R. Gopalan, and G. Sundararajan, “Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance”, Journal of Manufacturing Processes, Vol. 49, p 463-471, 2020.

- V. Rao Rikka, S. R, Sahu, R. Tadepalli, R. Bathe, T. Mohan, R. Prakash, G. Padmanabham and R. Gopalan, "Microstructure and mechanical properties of pulse laser welded SS and Al Alloys for lithium-Ion cell casings", Journal of Materials Science and Engineering B, 6, 2016, 218-225.

- R. Vallabha Rao, S.R. Sahu, P.V. Satyam, R. Prakash, M.S. Ramachandra Rao , R. Gopalan and G. Sundararajan, "In Situ/ex Situ Investigations on the Formation of the Mosaic Solid Electrolyte Interface Layer on Graphite Anode for Lithium-Ion Batteries", Journal of Physical Chemistry C Vol.122 (50), p 28717-28726 , 2018

- S.R. Sahu, V.R. Rikka, M. Jagannatham, P. Haridoss, A. Chatterjee, R. Gopalan and R. Prakash, "Synthesis of Graphene Sheets from Single Walled Carbon Nanohorns: Novel Conversion from Cone to Sheet Morphology", Materials Research Express, Vol. 4(3), Article No. 035008, 2017.

- S. Bhubaneswari, UV Varadaraju, R. Gopalan and R. Prakash “Sc-doping induced cation-disorder in LiNi0.5Mn1.5O4 spinel leading to improved electrochemical performance as cathode in lithium ion batteries”, Electrochimica Acta, Vol.327, Article No. 135008, 2019.

- S. Bhuvaneswari, U.V.Varadaraju, R.Gopalan and RajuPrakash, "Structural stability and superior electrochemical performance of Sc-doped LiMn2O4 spinel as cathode for lithium ion batteries", Electrochimica Acta, Vol. 301, p 342-351, 2019.

- Comprehensive effort on electrode slurry preparation for better electrochemical performance of LiFePO4 battery Kumari Konda, Sahana B. Moodakare, P. Logesh Kumar, Manjusha Battabyal, Jyoti R. Seth, Vinay A. Juvekar, Raghavan Gopalan, Journal of power sources, 480 (2020) 228837

- V. V. N. Phanikumar, Vallabha Rao Rikka, Bijoy Das, Raghavan Gopalan, B. V. Appa Rao and Raju Prakash, "Investigation on polyvinyl alcohol and sodium alginate as aqueous binders for lithium-titanium oxide anode in lithium-ion batteries, Ionics, 2019, Volume 25, Issue 6, pp 2549–2561.

- V. V. N. Phanikumar, B. V. A. Rao, K. V. Gobi, R. Gopalan and R. Prakash, “A sustainable tamarind kernel powder based aqueous binder for graphite anode in lithium-ion batteries”, vol 5, p 1199-1208, 2020

- Concentration Gradient-Driven Aluminum Diffusion in a Single-Step Coprecipitation of a Compositionally Graded Precursor for LiNi0.8Co0.135Al0.065O2 with Mitigated Irreversibility of H2 ↔ H3 Phase Transition, Sasikala Natarajan, Sahana B. Moodakare, Prathap Haridoss and Raghavan Gopalan, ACS Appl. Mater. Interfaces 2020, 12, 31, 34959–34970

- S. Vasu, Moodakare B. Sahana, Chandran Sudakar, R. Gopalan, G. Sundararajan, "In-situ carbon encapsulation of LiNi1/3Co1/3Mn1/3O2 using pillared ethylene glycol trapped in the metal hydroxide interlayers for enhanced cyclic stability," Electrochimica Acta 251, 363-377.

- Sasikala Natarajan, Sahana B. Moodakare, Vasu Shanmugam, Prathap Haridoss, and Raghavan Gopalan, "Infrared Spectroscopic signatures of Aluminium segregation and Partial Oxygen substitution by Sulphur in LiNi0.8Co0.15Al0.05O2", ACS Appl. Energy Materials, Vol. 1(6), p 2536-2545, 2018.

- S. R. Sahu, D. Parimala Devi, V. V. N. Phanikumar, T. Ramesh, N. Rajalakshmi, G. Praveena, R. Prakash, B. Das, R. Gopalan, "Tamarind seed skin derived fibre-like carbon nanostructures as novel anode material for lithium-ion battery", Ionics , volume 24, Issue 11, pp 3413–3421.

New soft magnetic steel alternate to Si-steel

Overview

Soft magnetic steel forms an essential component in all motors and alternators used in the automotive industry. Currently for high efficient motors Si steel (typical Si content ~2%) is being used. The ever increasing demand to phase out fossil fuel automotives and move to electric driven vehicles requires high performance motors. Hence there is a focus on alternate soft magnetic material which is cost effective and with better magnetic properties compared to Si steel. In this background we propose Fe-P as a potential alternate which is cost effective and with magnetic properties equivalent/better than Si steel. Fe-P based alloy prepared by wrought metallurgy process of induction melting, forging, hot rolling and subjected to a suitable two step heat treatment process yield soft magnetic materials with properties equivalent or better than Si steel. The formation of fine nano-precipitates of Fe3P enhances the resistivity of the alloy lowering the core loss at high frequency. Currently we have developed alloys with coercivity less than 1 Oe and a core loss of 187 W/kg at 1 kHz measured at Bmax 1 T

Key Features

- Industrially viable wrought metallurgy process

- Alloy produced from low cost raw materials (cost effectiveness)

- Better mechanical properties advantages of machinability

- Good magnetic properties equivalent/better than commercial materials

Potential Applications

- Used in alternators of automobiles

- Used in manufacture of various motors used in automobiles

- Explored for applications involving magnetic switching in valves and switch gears.

Intellectual Property Development Indices (IPDI)

- Magnetic properties measured and benchmarked with standard commercial materials

- Prototypes produced and being benchmarked with commercially used machines

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Publications

- Effect of Si addition on AC and DC magnetic properties of (Fe-P)-Si alloy, AIP Advances 6, 055921 (2016)

- AC magnetic properties and core loss behaviour of FeP soft magnetic sheets, IEEE Transactions on Magnetics 50 (2014) 2008604

- High saturation magnetization in Fe-0.4 wt.% P alloy processed by a two-step heat treatment Journal of Magnetism and Magnetic Materials 345 (2013) 239.

- Effect of recovery and recrystallization on microstructure and magnetic properties of Fe-0.4 P rolled sheets, Materialia 13 (2020) 100863

- Influence of nanoprecipitates, solid solution and grain size on the magnetic and electrical properties of Fe-P-Si alloys, Journal of Magnetism and Magnetic Materials 493 (2020) 165743

Waste Heat Recovery using Thermoelectric modules

Overview

Conversion of heat generated and let out in atmosphere in various industrial processes to electricity have the dual benefit of improving environment by decreasing greenhouse gas emission and higher system efficiency. Thermoelectric (TE) technology is one of the most reliable method for converting such wasted heat into electric energy free from any pollution and noise making moving parts. Automotive exhaust waste heat conversion is one application extensively researched by many automobile manufacturers as the world is currently facing numerous problems due to the increasing demand in energy for sustainable transportation. It is calculated that 33% of total fuel energy in automobiles is wasted as exhaust gas. Hence TE technology can play a vital role in automobiles by converting the waste heat into electricity. Converting the waste heat generated from steel, cement, glass industries are some of the other applications being developed. Utilizing the heat from solar panel, concentrated solar thermal heat to power by thermoelectric are some of the other applications being explored.

Key Features

- Scalable inorganic thermoelectric materials technology to fabricate P and N type bulk solids with ZT more than 1.5 and chemically and structurally stable up to 500°C.

- Fabrications know how for making thermoelectric modules from the ZT > 1.5 materials. Developed and patented. Ready for upscaling.

- Demonstration of TE generator technology with more than 5 % efficiency to convert heat from various sources. TEG design, validation, performance testing, field trials.

Potential Applications

- Electricity from diesel engine exhaust heat in automobiles, community incinerators and solar thermic fluid.

- Power generation from steel plant, glass melting plant waste heat.

- Power from domestic heat source like wood stove.

Intellectual Property Development Indices (IPDI)

- Scalable inorganic thermoelectric materials with figure of merit (ZT) 1.3 and abobe

- Thermoelectric modules fabrication technology (TRL 5 level), Patent Filed

- Thermoelectric generator (TEG) technology for various applications (TRL 5 level) e.g. Automobile, steel industries.

| Status | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

Major Patents / Publications

Major Patents*

- D.Sivaprahasam, B.Jayachandren, B.Prashant, R.Gopalan, “A method of preparing the thermoelectric module for power generation from automotive exhaust and the thermoelectric module thereof” Indian Patent filed

Major Publications

- M.Battabyal, B.Priyadarshini, D.Sivaprahasam, R. Gopalan, 2015. “Effect of Cu2O nanoparticle dispersion on thermoelectricproperties of n-type skutteudites”, J of Phys. D: Appl.Phys. 48, 455309. (2015)

- S.Harish, D.Sivaprahasam, M.Battabyal, R.Gopalan, 2016, “Phase stability and thermoelectric properties of Cu10.5Zn1.5Sb4S13 tetrahedrites” J of Alloys and Compound” 667, (2016) Pp. 323-328.

- B.Priyadarshni, M.Battabyal, D.Sivaprahasam, R.Gopalan, “On the formation of phases and their influence on the thermal stability and thermoelectric properties of nanostructured zinc antimonide”, J of Phys. D: Appl.Phys. 50, 015602. (2017)

- V Trivedi, M Battabyal, P Balasubramaniam, GM Muralikrishna, PK Jain, Microstructure and doping effect on the enhancement of thermoelectric properties in Ni doped Dy filled CoSb3 skutterudites, Sustainabale Energy & Fuels 2, (2018) 2687.

- M.Battabyal, P.Balasubramanian, PM.Geetu, L.Pradipkanti, DK Stapathy, R.Gopalan, Tailoring the optical phonon modes and dielectric properties of nanaocrystalline SrTiO3 via Yb doping, Materials research Express, 5, 046301. (2018)

- K.Muthamilselvan, M.Mayarani, GM Muralikrishna, M.Battabyal, Tuning the optical and thermoelectric properties of SrTiO8-xSn0.2FexO3 Materials research Express, 6, (2019) 045905

- B.Priyadarshini, M.battabyal, D.Das, AC Bose, R.Gopalan, tuning of Mg content to enhance the thermoelectric properties in binary Mg2+δSi (δ=0,0.1,0.15,0.2) materials Research Express, 6, (2019) 125519.

- B.Jayachandren, Titas Dasgupta, R.Gopalan, D.Sivaprahasam, “Elevated temperature behavior of CuPb18SbTe20/n-Ag/Cu joints for thermoelectric devices” J of Electronic Materials, 48 (2), 1276-1285 (2019)

- D.Sivaprahasam, Thermal conductivity of nanostructured Fe0.04CoSb3 Skutterudite, Materials Letter 252 (2019) 231-234.

- M.Battabyal, NS Karthisrlva, P.Rejesh, R.Gopalan, Pressure induced enhancement in the thermoelectric and mechanical properties of Ni doped skutteridites during spark plasma sintering. Materials research innovations, 2020.

- S.Harish, D.Sivaprahasam, R.Gopalan, G.Sundararajan, Design and development of new test rig for testing of automotive thermoelectric generator’ AIP Advances 9 (2019) 065004

- B.Prashant B. Prasanth a, B. Jayachandren a, Neha Hebalkar b, R. Gopalan a, S.B. Chandrasekhar b, D. Sivaprahasam a, Improved thermal stability of thermoelectric Mg2Si0.4Sn0.6, Materials Letters 276 (2020) 128204.

- B. Jayachandran, B. Prasanth, R. Gopalan, T. Dasgupta, D. Sivaprahasama, Thermally stable, low resistance Mg2Si0.4Sn0.6/Cu thermoelectric contacts using SS 304 interlayer by one step sintering., Materials Research Bulletin 136 (2021) 111147.

- V.Trivedi, M.Battabyal, S.Perumal, A.Chauhan,D.K.Satapathy, BS Murty, R.Gopalan, Effect of refractory tantalum metal filling on the microstructure and thermoelectric properties of Co4Sb12 skutterudites. ACS Omega, 2021.

.png)